Method for detecting radioactive separation degree in lanthanum chloride and its application

A technology of separation degree and lanthanum chloride, which is applied in the field of detection of radioactive separation degree in lanthanum chloride, can solve the problems such as long detection period of radioactive removal degree, achieve simple and convenient experiment and analysis process, strong practicability, and shorten detection time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The method for detecting the degree of radioactive separation in lanthanum chloride provided by the present embodiment is specifically:

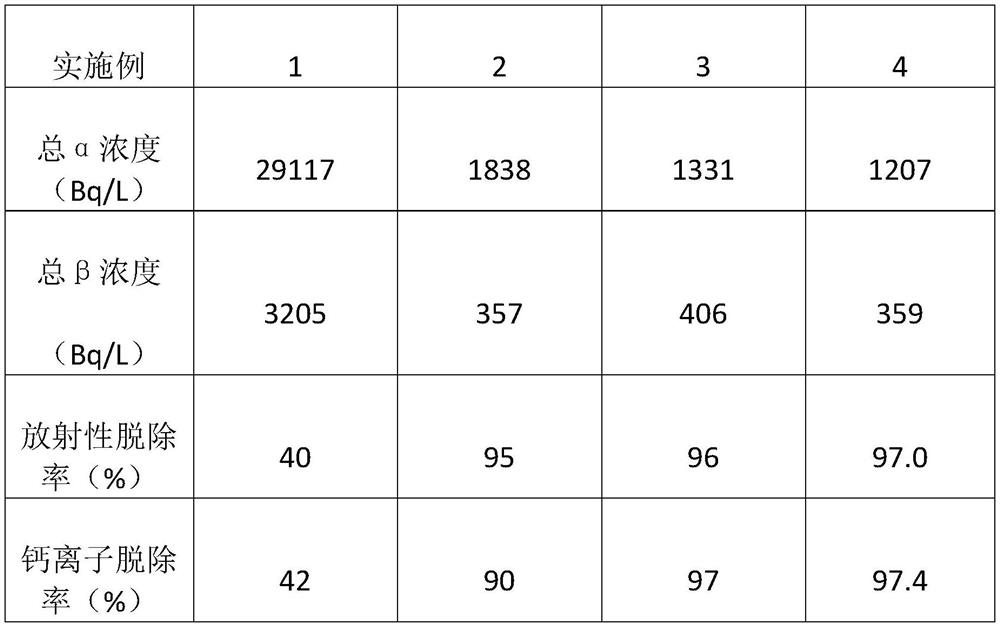

[0042] The lanthanum chloride mixed solution with a volume of 1L adopts the P507-kerosene extractant whose concentration is 1.5mol / L and saponification rate of 45% with a volume of 7L. After 10 stages of extraction and separation of radioactive elements, the loaded lanthanum extractant is obtained. The hydrochloric acid solution that volume is 1.05L carries out back extraction as stripping agent to load lanthanum extractant, and Ca in hydrochloric acid solution 2+ Concentration is 20mg / L, HCl concentration is 4.5mol / L, obtains lanthanum feed liquid, and La in lanthanum feed liquid 3+ The concentration is 1.4mol / L, Ca 2+ The total removal rate of calcium from the initial lanthanum chloride mixed solution to the lanthanum feed solution is about 42%. According to the removal rate of calcium, it can be known that the radioactive removal...

Embodiment 2

[0044] The method for detecting the degree of radioactive separation in lanthanum chloride provided by the present embodiment is specifically:

[0045] The lanthanum chloride mixed solution with a volume of 1L adopts the P507-kerosene extractant with a volume of 20L of P507 concentration of 1.2mol / L and a saponification rate of 20%. After 18 stages of extraction and separation of radioactive elements, the loaded lanthanum extractant is obtained. A volume of 1.1L hydrochloric acid solution is used as a stripping agent to back-extract the loaded lanthanum extractant, and Ca in the hydrochloric acid solution 2+ Concentration is 20mg / L, HCl concentration is 4.5mol / L, obtains lanthanum feed liquid, and La in lanthanum feed liquid 3+ The concentration is 1.35mol / L, Ca 2+ It is 171mg / L. The total removal rate of calcium from the initial lanthanum chloride mixed solution to the lanthanum feed solution is calculated to be about 90%. It can be seen that the radioactivity removal degr...

Embodiment 3

[0047] The method for detecting the degree of radioactive separation in lanthanum chloride provided by the present embodiment is specifically:

[0048] The mixed solution of lanthanum chloride with a volume of 1L adopts the P507-kerosene extractant whose concentration is 1.8mol / L and saponification rate of 36% to obtain the first solution after 27 extraction and separation of the radioactive elements with a volume of 6L. The hydrochloric acid solution of 1L is carried out back extraction to the first solution as stripping agent, and Ca in the hydrochloric acid solution 2+ Concentration is 20mg / L, HCl concentration is 4.5mol / L, obtains lanthanum feed liquid, and La in lanthanum feed liquid 3+ The concentration is 1.48mol / L, Ca 2+ It is 58mg / L. The calculated total removal rate of calcium from the initial lanthanum chloride mixed solution to the lanthanum feed solution is about 97%. According to the removal rate of calcium, it can be seen that the degree of radioactive remova...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com