Methods and systems for inline parts average testing and latent reliability defect detection

A technology of average testing and reliability, applied in registration/indicating quality control system, semiconductor/solid-state device testing/measurement, measuring electricity, etc., can solve problems such as reliability failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Reference will now be made in detail to the disclosed subject matter which is illustrated in the accompanying drawings.

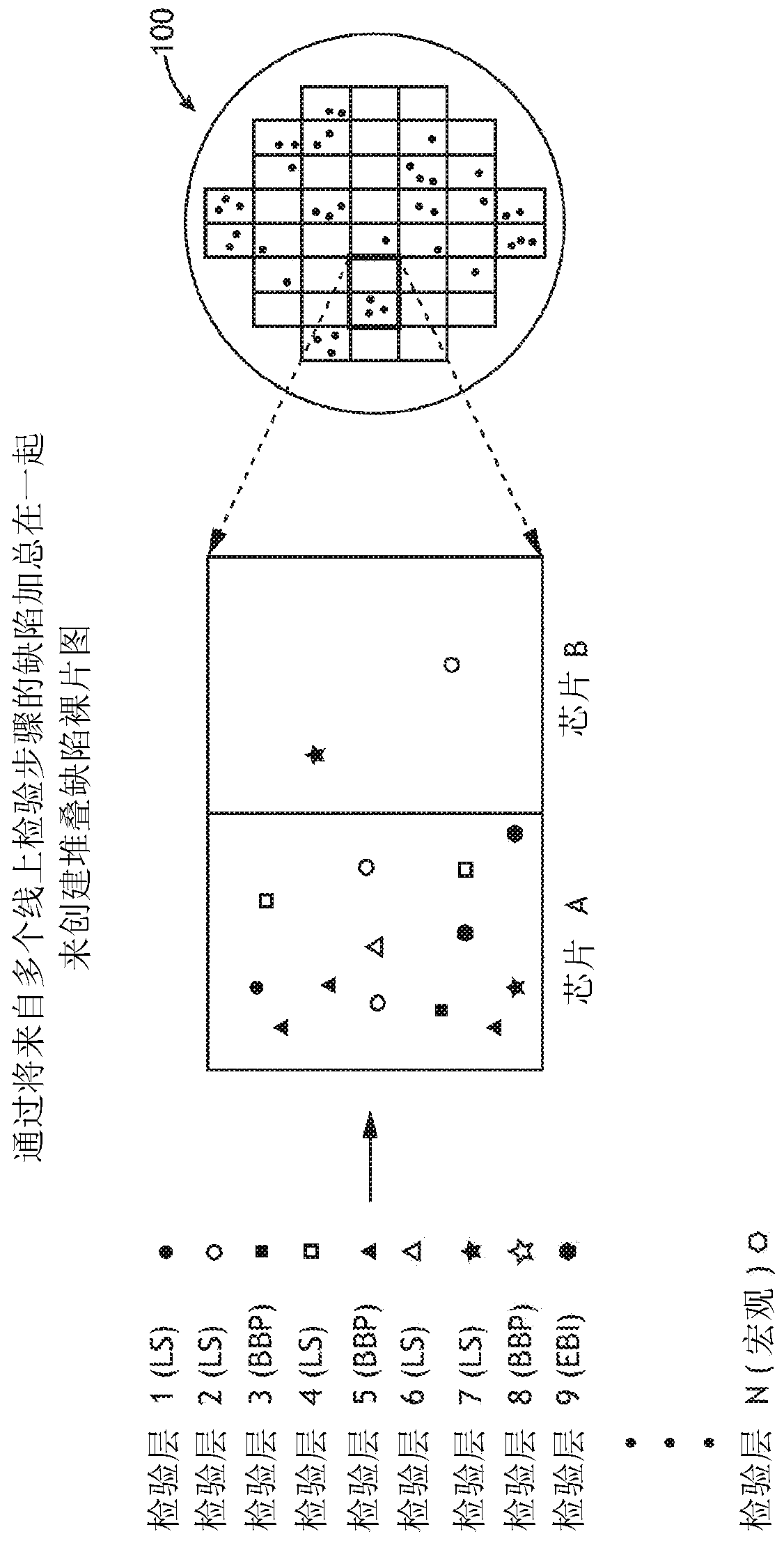

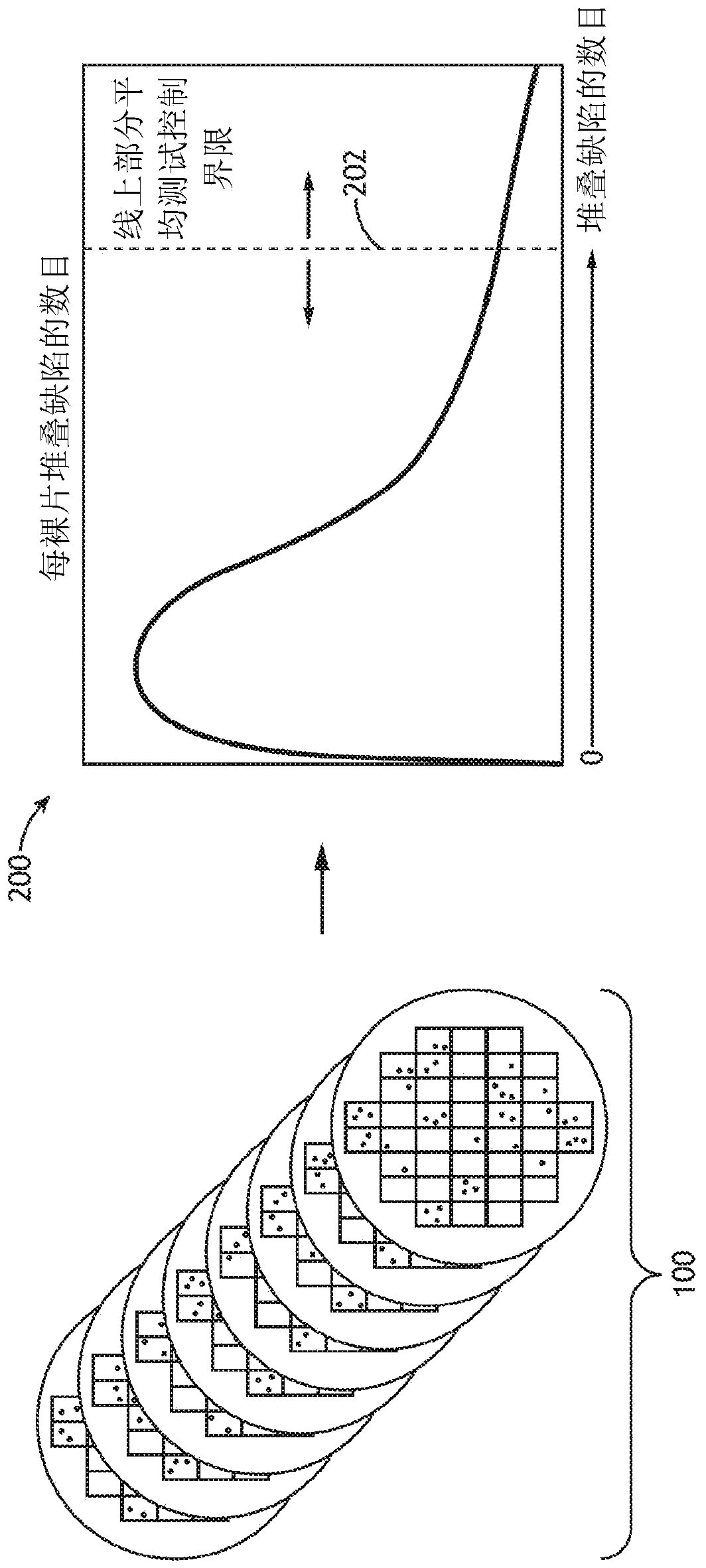

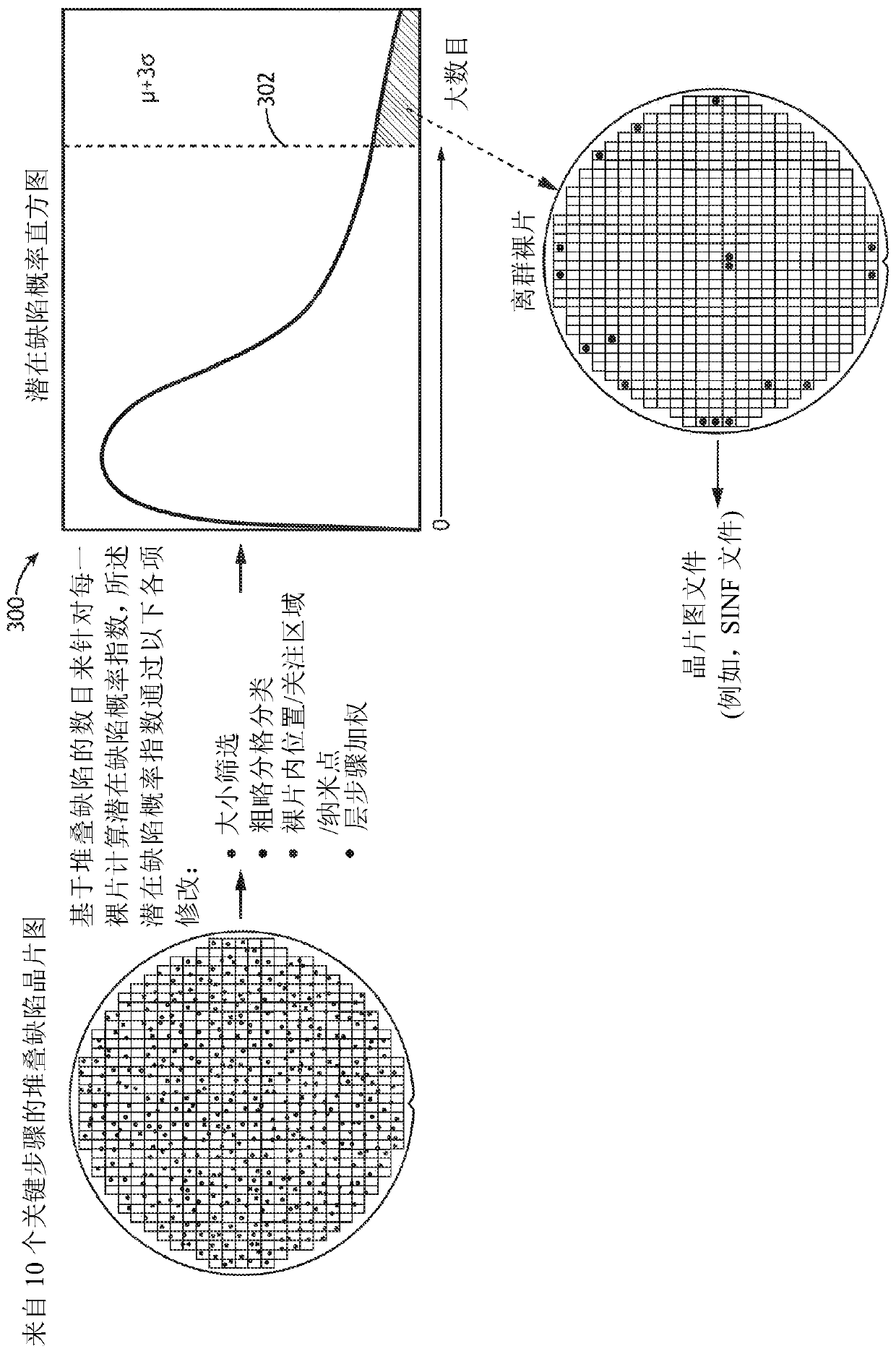

[0017] Embodiments of the present invention are directed to methods and systems for in-line partial averaging testing and potential reliability defect identification and / or detection. A latent reliability defect refers to a defect from manufacturing present in a device that passes initial quality testing but still results in premature failure when activated in its operating environment. For example, wafers can be fabricated and used to produce various types of semiconductor electronic components. These semiconductor electronic components can then be used in the field for various purposes (e.g., they can be incorporated into automobiles or other types of vehicles that require high reliability or low field failure rates, aircraft, military, medical, and other devices) and Operates in various types of environments. Some of these semiconductor electron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com