Bone bar meat slice pressing equipment

A technology of meat slices and equipment, applied in the direction of feed, food science, application, etc., can solve the problems of low production efficiency, time-consuming and laborious, and a large number of manual operations, and achieve high production efficiency, small manual operation burden, and easy maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

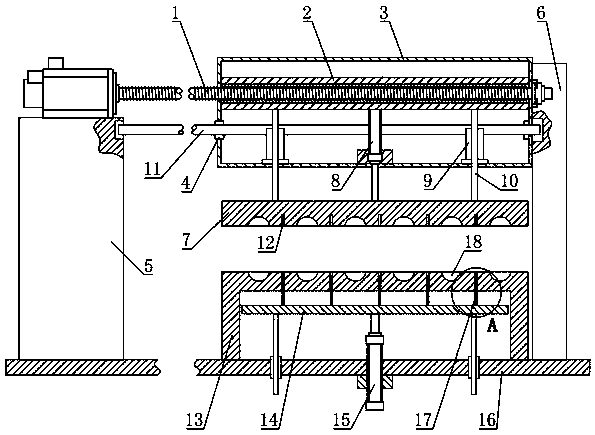

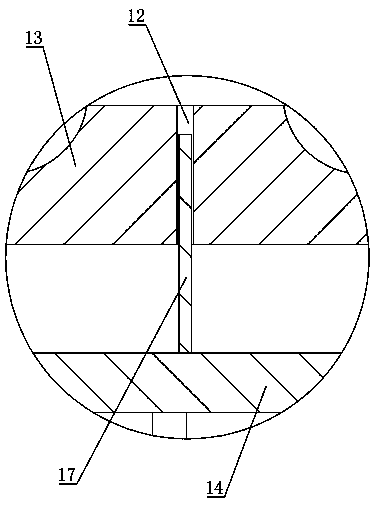

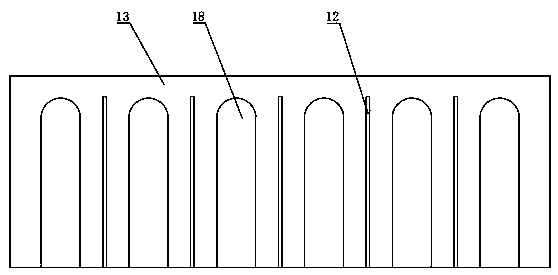

[0021] Please refer to the attached figure 1 , a kind of bone stick meat piece pressing equipment of the present invention, comprises workbench 16, and described workbench 16 is equipped with lower mold 13, and the top of workbench 16 is installed with the upper mold frame 3 that lower mold 13 is arranged at intervals, and upper mold The lower part of the frame 3 is vertically slidably equipped with a patrix 7 driven by a lifting mechanism. A plurality of die grooves 18 are correspondingly provided on the working surfaces of the patrix 7 and the lower die 13, and a knife is provided between two adjacent die recesses 18. The groove 12, the knife groove 12 on the upper mold 7 and the lower mold 13 are correspondingly arranged, and an avoidance passage is provided between the upper mold 7 and the workbench 16, and a vertical slide is installed on the workbench 16, which is driven by a lifting mechanism and located in the avoidance channel. The knife rest 14 in the channel, the cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com