A kitchen food waste disposer

A food waste treatment and kitchen technology, applied in grain treatment, chemical/physical processes, chemical instruments and methods, etc., can solve the problem of clogging the discharge pipe, unfavorable reuse, and adhesion of garbage debris to the inner wall of the discharge pipe and other problems to achieve the effect of ensuring uniformity and avoiding clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

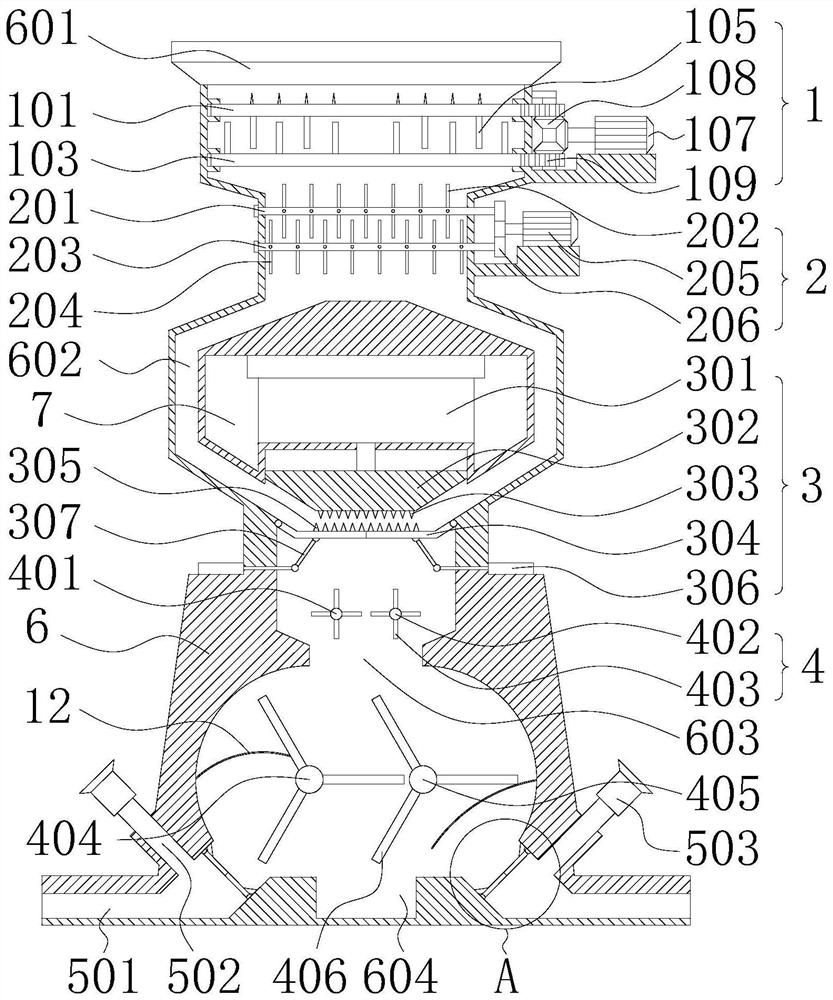

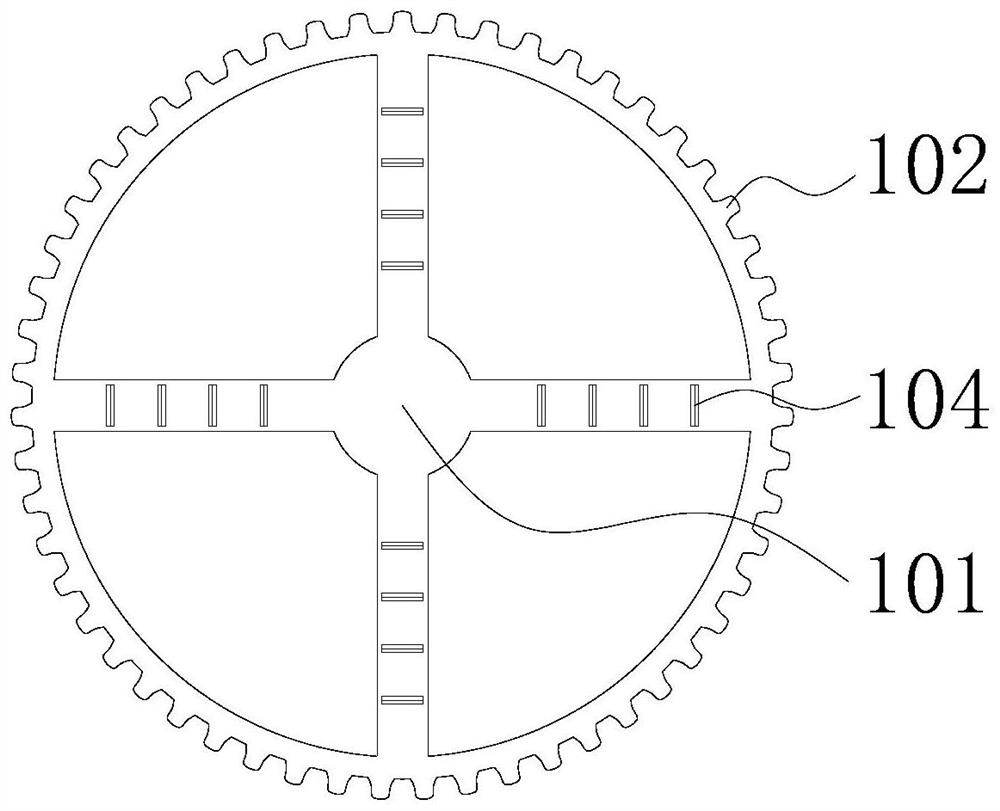

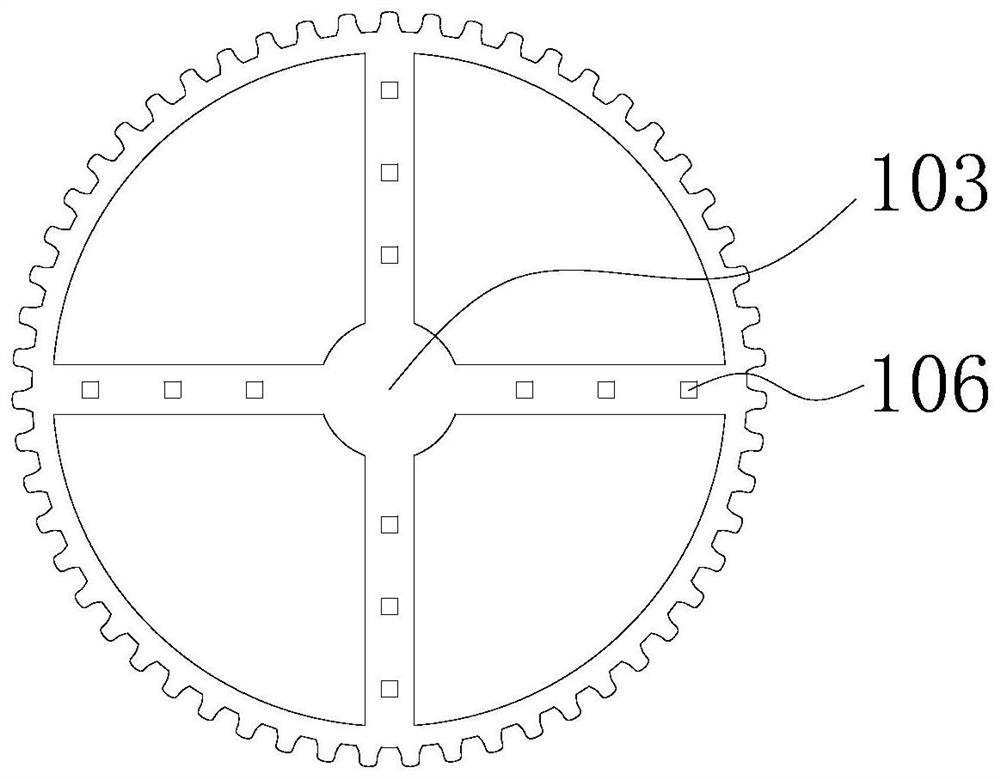

[0033] like figure 1 and Figure 4 As shown, this embodiment provides a kitchen food waste disposer, which includes a primary stirring mechanism 1 , a secondary stirring mechanism 2 , a crushing mechanism 3 , a screening mechanism 4 and a discharge mechanism 5 from top to bottom. The primary stirring mechanism 1 comprises a first stirring disc 101, a gear tooth 102, a second stirring disc 103, a blade 104, a first stirring rod 105, a second stirring rod 106, a first motor 107, a bevel gear 108 and a first gear 109 . The secondary stirring mechanism 2 includes a first stirring roller 201 , a third stirring rod 202 , a second stirring roller 203 , a fourth stirring rod 204 , a second motor 205 , a second gear 206 and a hook 207 . The crushing mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com