Processing technology of starting transmission gear

A processing technology and transmission gear technology, which is applied in the processing technology field of starting transmission gears, can solve the problems of difficult processing of gear discs, high scrap rate, and heat treatment that cannot meet the requirements of differentiation, so as to achieve optimized machining steps and low scrap rate , significant economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Embodiment 1: A kind of processing technology of starting transmission gear, it adopts to separately process the gear plate N and the gear cover M respectively first, and then combine the gear plate N and the gear cover M to process;

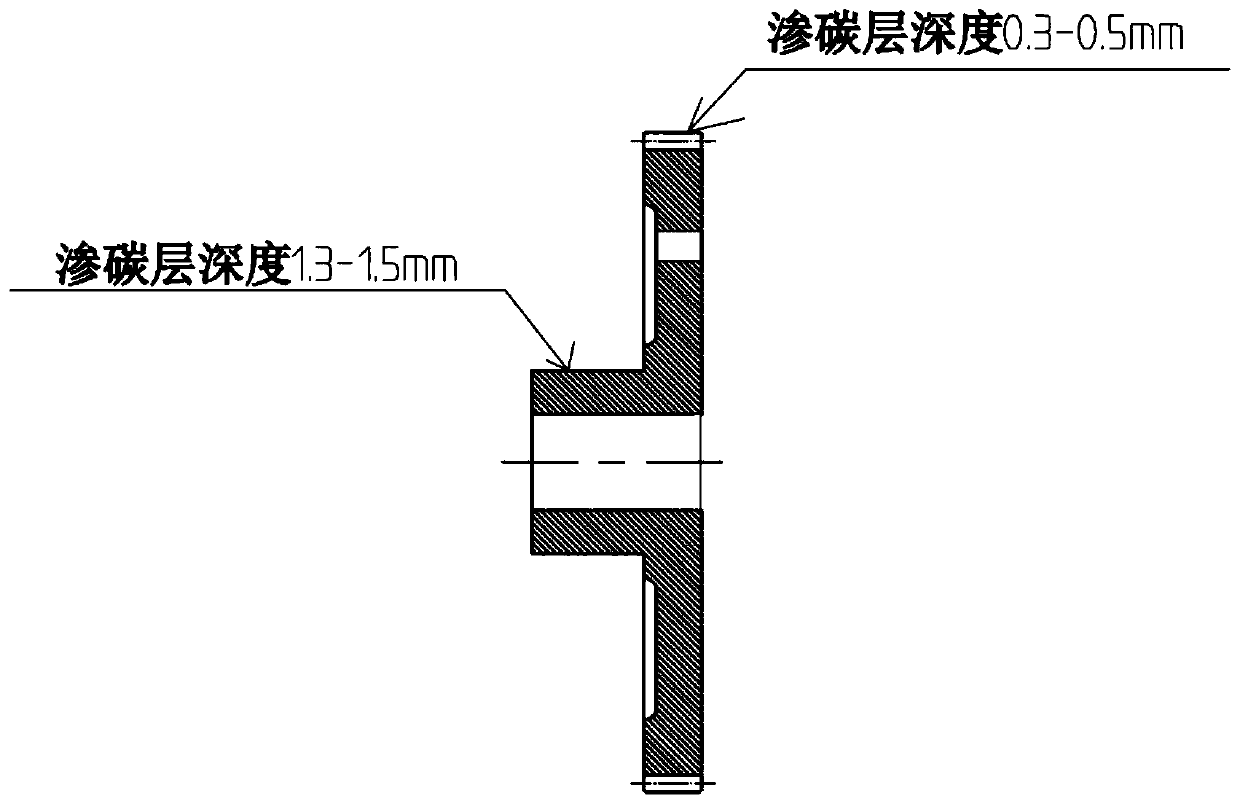

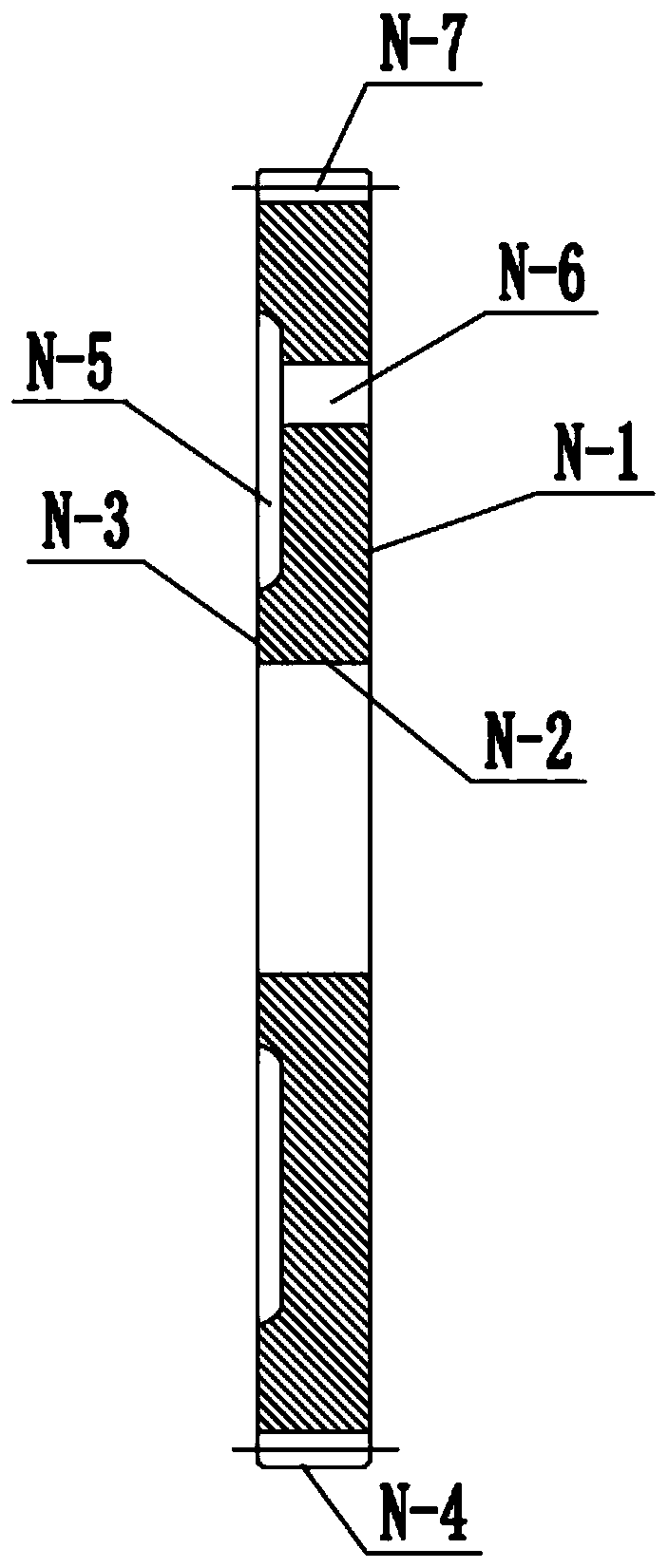

[0068] Among them, see figure 2 , the gear plate N adopts 20CrMo material, and its separate processing steps include:

[0069] a1) forging to obtain a blank;

[0070] a2) Finishing the first end surface N-1 and the first inner hole N-2;

[0071] a3) The second end surface N-3, the first outer circle N-4 and the sinking platform N-5 of the finish car;

[0072] a4) drilling or punching N-6;

[0073] a5) hobbing N-7;

[0074] a6) Deburring;

[0075] a7) Inspection;

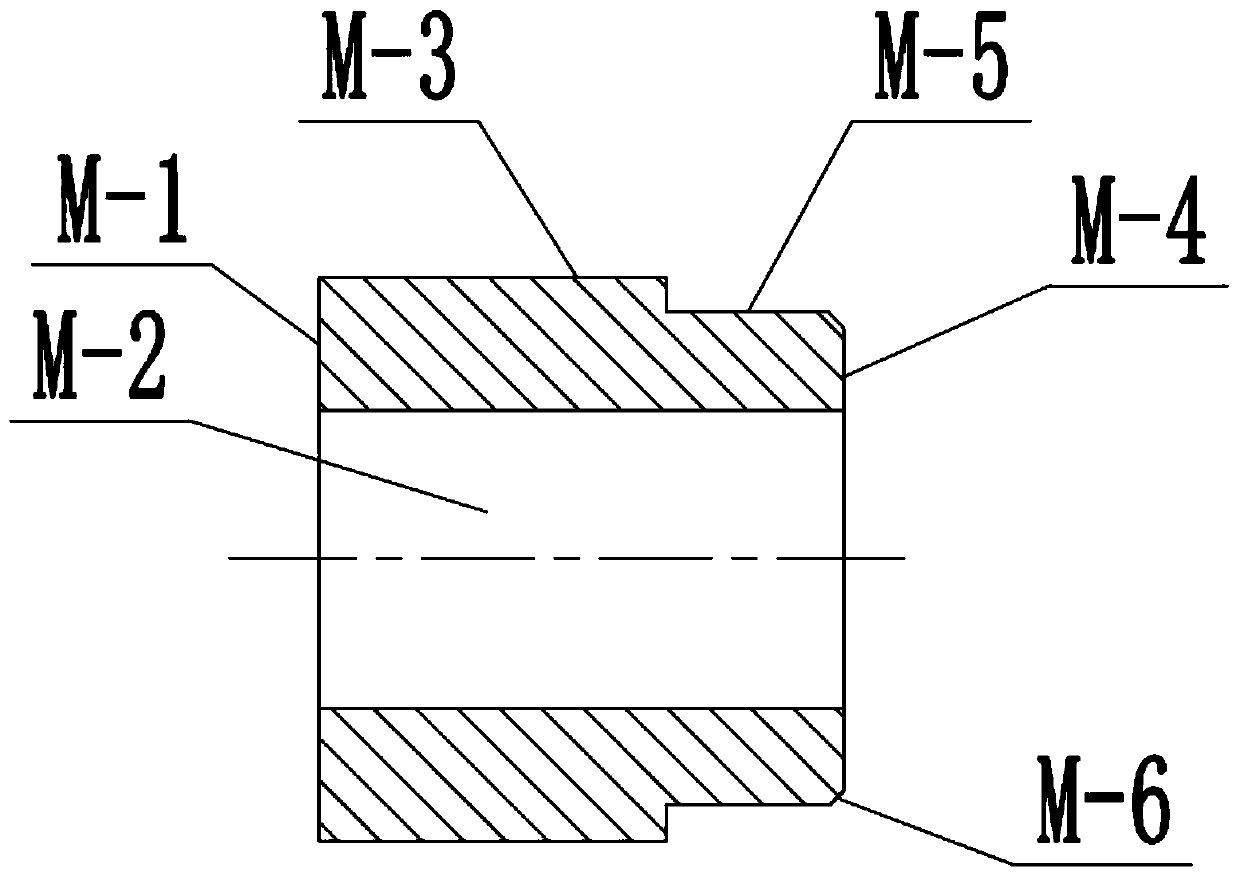

[0076] Among them, see image 3 , the gear sleeve M is made of 20CrMo material, and its separate processing steps include:

[0077] b1) forging to obtain a blank;

[0078] b2) Finishing the third end surface M-1, the second inner hole M-2 and the second outer circle M-3;...

Embodiment 2

[0111] Embodiment 2: A kind of processing technology of starting transmission gear, it adopts to separately process the gear plate N and the gear sleeve M respectively first, and then the gear plate N and the gear sleeve M are processed in combination;

[0112] Among them, see figure 2 , the gear plate N adopts 20CrMo material, and its separate processing steps include:

[0113] a1) forging to obtain a blank;

[0114] a2) Finishing the first end surface N-1 and the first inner hole N-2;

[0115] a3) The second end surface N-3, the first outer circle N-4 and the sinking platform N-5 of the finish car;

[0116] a4) drilling or punching N-6;

[0117] a5) hobbing N-7;

[0118] a6) deburring;

[0119] a7) Inspection;

[0120] Among them, see image 3 , the gear sleeve M is made of 20CrMo material, and its separate processing steps include:

[0121] b1) forging to obtain a blank;

[0122] b2) Finishing the third end surface M-1, the second inner hole M-2 and the second out...

Embodiment 3

[0155] Embodiment 3: A kind of processing technology of starting transmission gear, it adopts to separately process the gear plate N and the gear cover M respectively first, and then the gear plate N and the gear cover M are processed in combination;

[0156] Among them, see figure 2 , the gear plate N adopts 20CrMo material, and its separate processing steps include:

[0157] a1) forging to obtain a blank;

[0158] a2) Finishing the first end surface N-1 and the first inner hole N-2;

[0159] a3) The second end surface N-3, the first outer circle N-4 and the sinking platform N-5 of the finish car;

[0160] a4) drilling or punching N-6;

[0161] a5) hobbing N-7;

[0162] a6) Deburring;

[0163] a7) Inspection;

[0164] Among them, see image 3 , the gear sleeve M is made of 20CrMo material, and its separate processing steps include:

[0165] b1) forging to obtain a blank;

[0166] b2) Finishing the third end surface M-1, the second inner hole M-2 and the second outer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com