Edge shoving mechanism for forming paper box, paper box forming machine and paper box forming process

A molding machine and carton technology, which is applied in paper/cardboard containers, papermaking, container manufacturing machinery, etc., can solve the problems of fast, efficient and accurate box molding, cumbersome box molding process control, and box molding accuracy. problems, to achieve the effect of improving the degree of integration and automation, high degree of openness, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

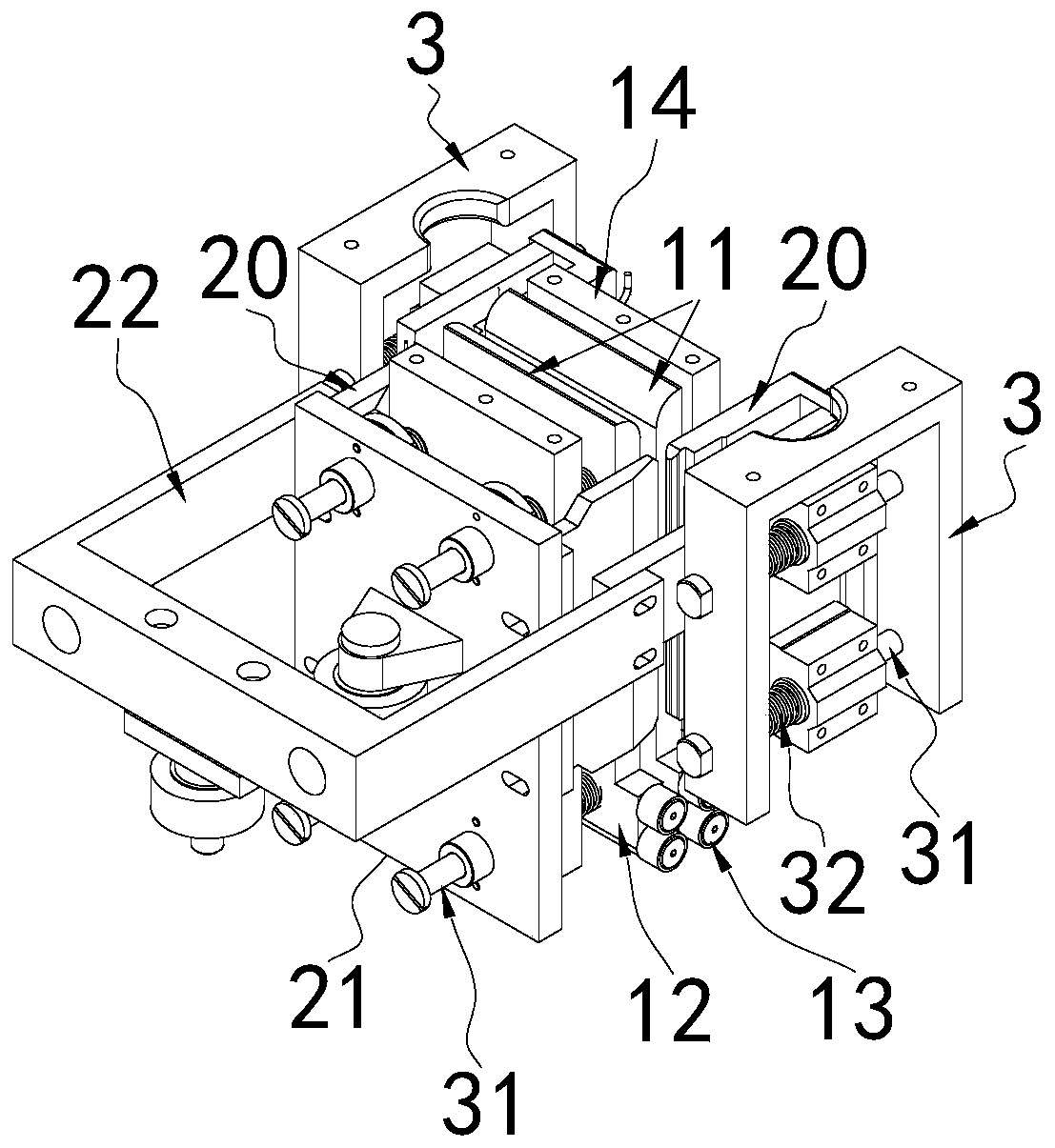

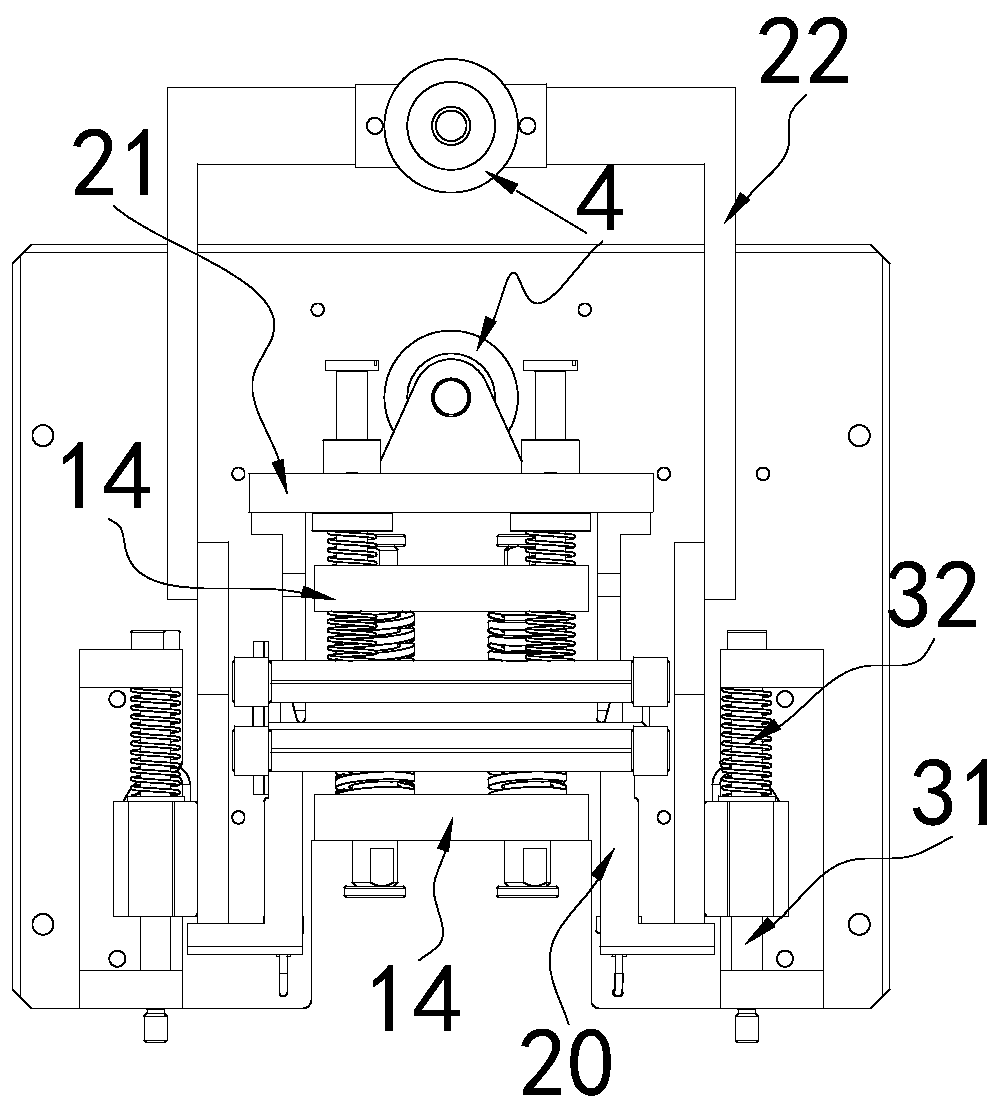

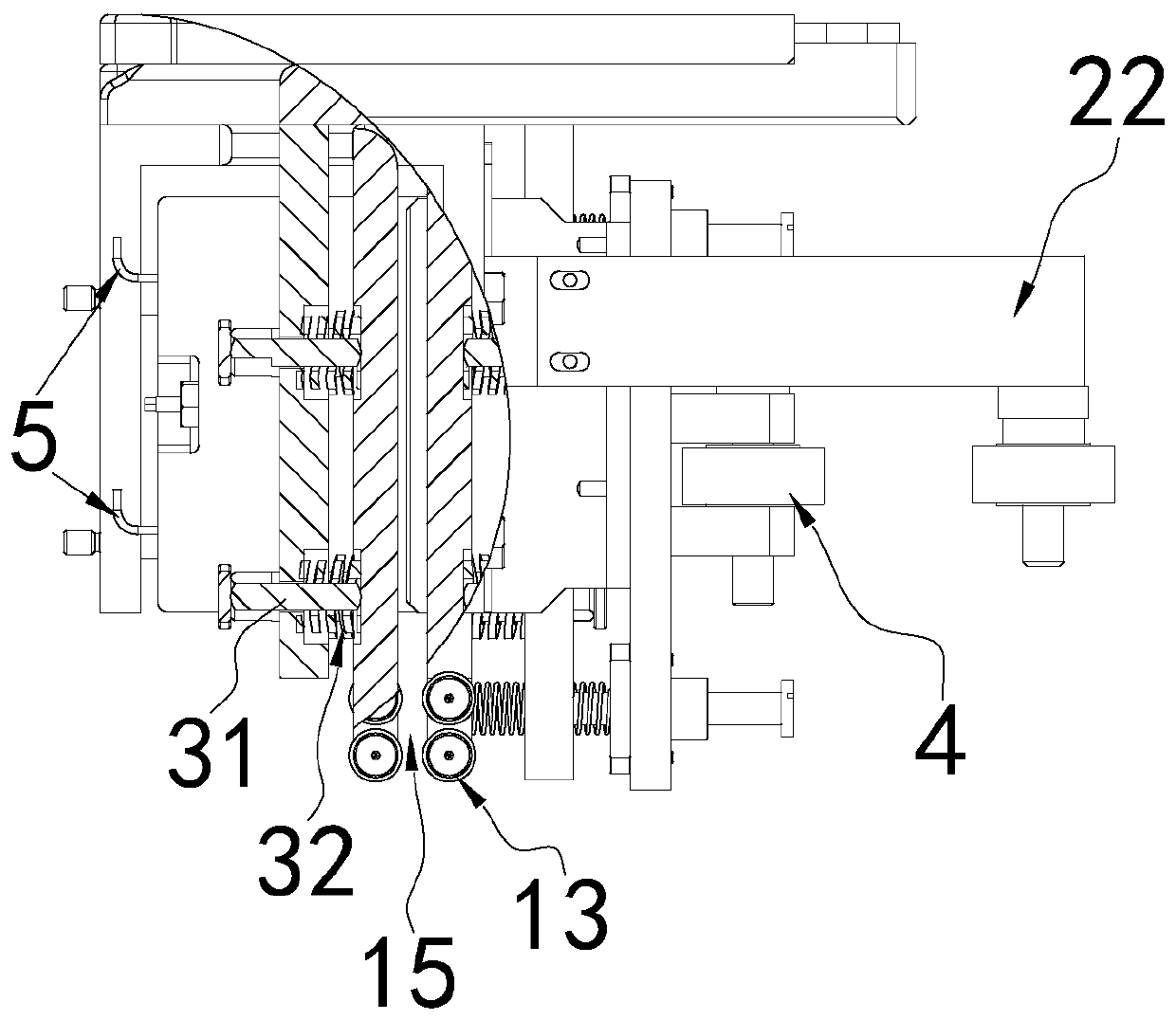

[0062] Such as Figure 1-15 as shown, figure 1 is the perspective view of the shovel edge mechanism, figure 2 Middle shovel edge mechanism has base plate 73, and this figure is looking up direction, image 3 for figure 2 partial sectional view.

[0063] combine Figure 1-3 A shoveling mechanism for carton forming provided by the present invention includes two opposite fixed plates 14 and two guide frames 3, a pair of parallel pressure plates 11 are arranged between the two fixed plates 14, and the pressure plates 11 and the fixed plate 14 are connected by an elastic guide assembly (guide shaft 31, spring 32); a first shoveling part 21 and a second shoveling part 22 are also included, and the first and second shoveling parts are both A shovel plate 20 is provided, and the shovel plate 20 is located on the side of the pressure plate 11, and the shovel plate 20 and the pressure plate 11 are perpendicular to each other; the first shoveling part 21 and the fixed plate 14 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com