Assembly type rope tightening device structure

A rope tightener and assembled technology, applied in the directions of transportation and packaging, vehicles used for freight, transport objects, etc., can solve the problems of loose ropes, displacement of goods, insufficient convenience, etc., to achieve tight connection and ensure stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

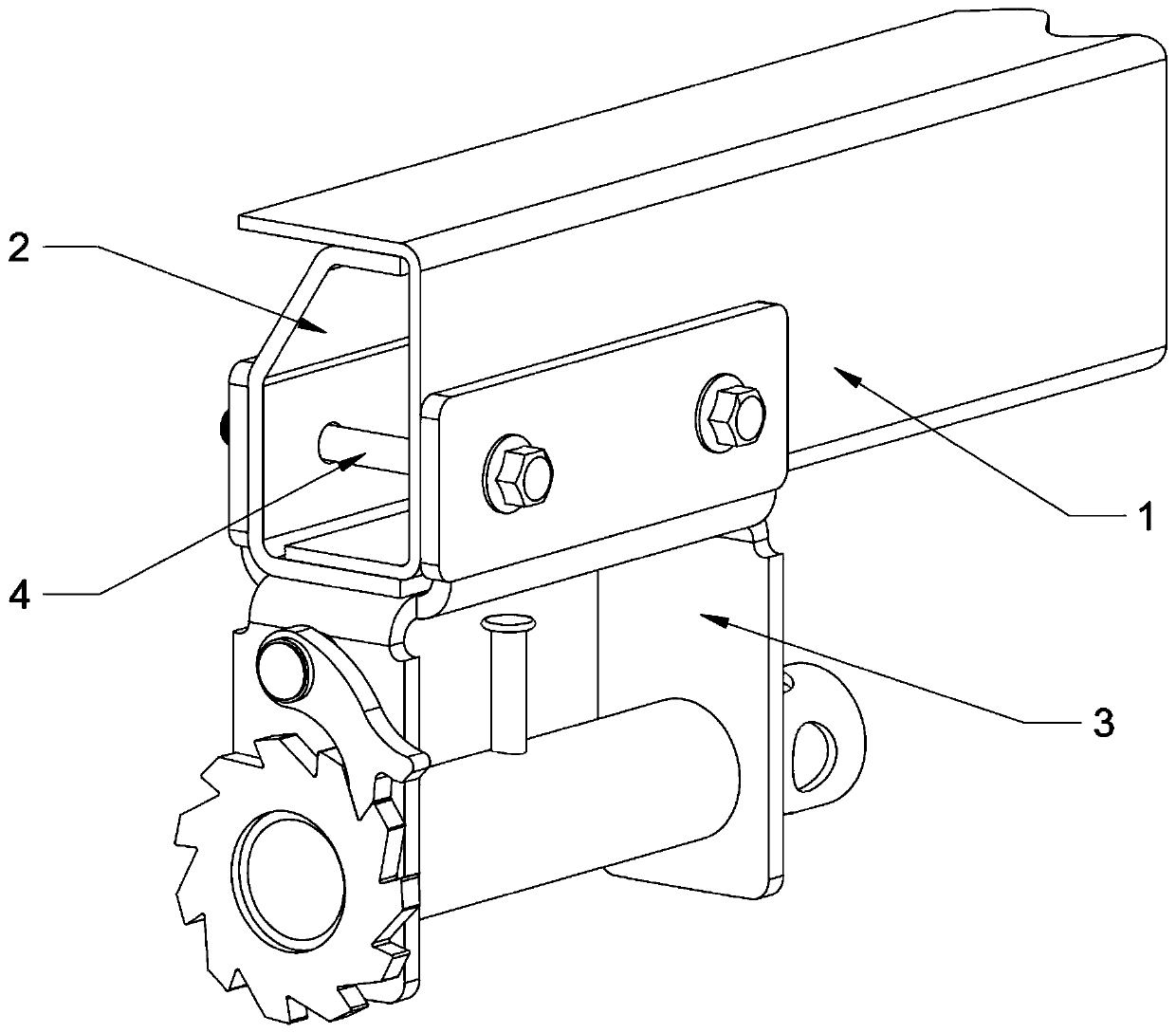

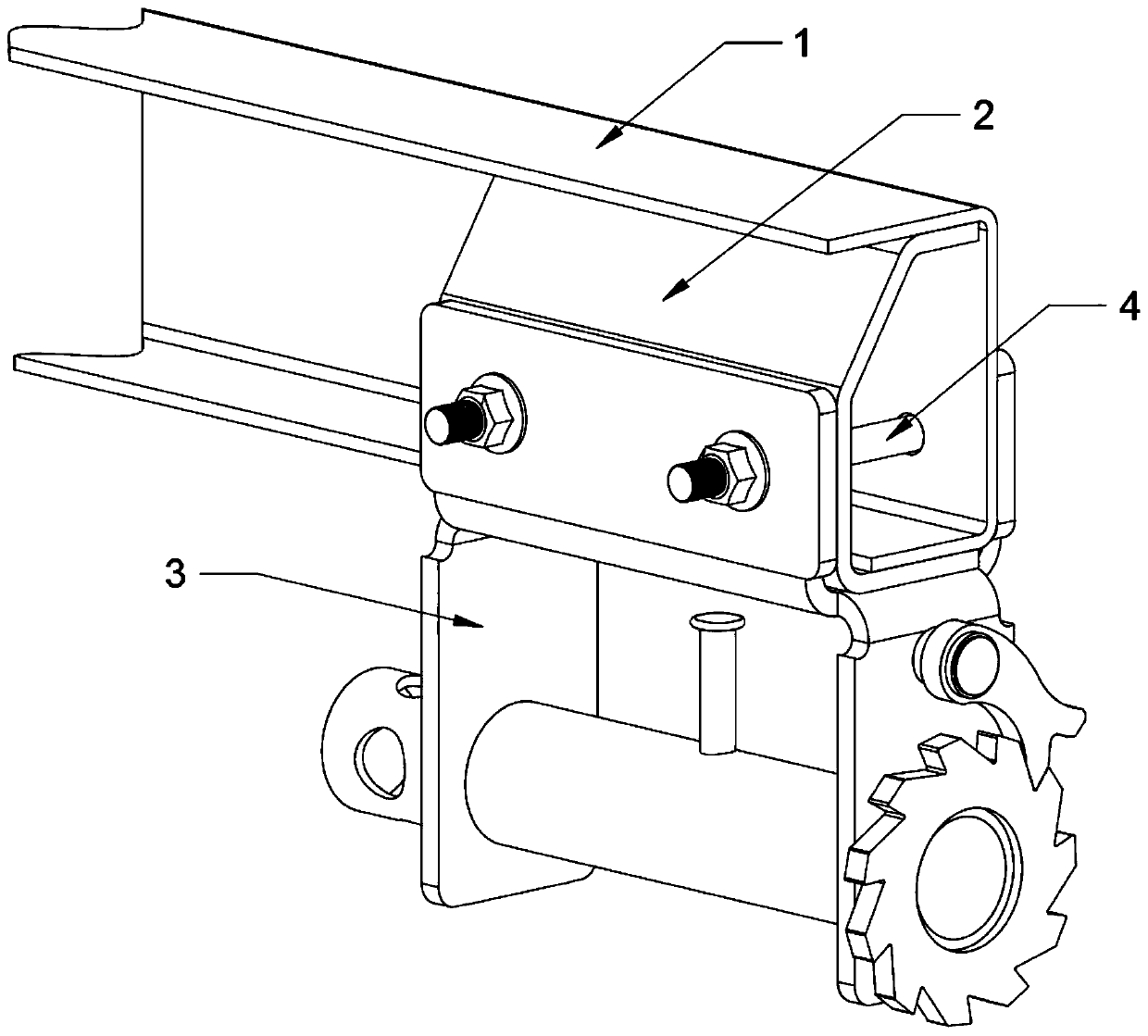

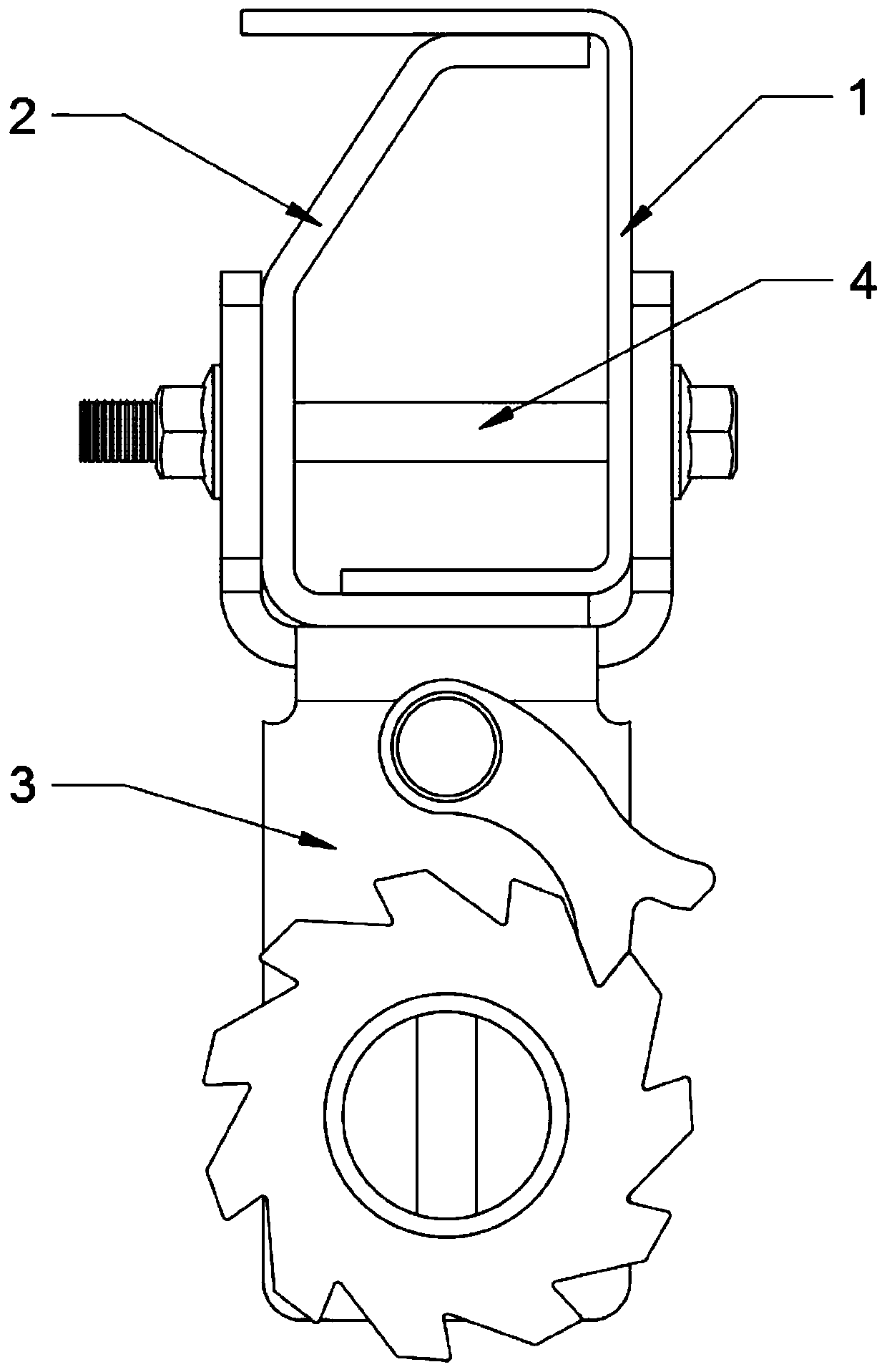

[0021] as attached figure 1 to attach Figure 4 Shown:

[0022] The present invention provides an assembled rope tightener structure, comprising a bottom plate frame 1, an outer assembly hole 101, a frame reinforcement 2, an inner assembly hole 201, an assembled rope tensioner 3, bolt connection holes 301 and bolts 4; the bottom plate There are two outer assembly holes 101 on the right side of the frame 1, and the right end of the bolt 4 is located inside the outer assembly holes 101; two inner assembly holes 201 are opened on the left side of the frame reinforcement 2, and the inner assembly holes 201 and the outer assembly holes 101 are equal in height, and the left end of the bolt 4 is located inside the inner assembly hole 201; two bolt connection holes 301 are respectively opened on the left and right sides of the top of the assembled rope tensioner 3, and the two bolts 4 are respectively installed in the assembled rope tensioner. 3 The top bolt is connected to the hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com