Hull protective structure of a fishing boat

A protective structure and hull technology, applied to fishing boats, hulls, and ship construction, can solve problems such as unfavorable long-term use of fiberglass fishing boats, damage to the outer surface of the hull, and impact on the service life of fishing boats

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

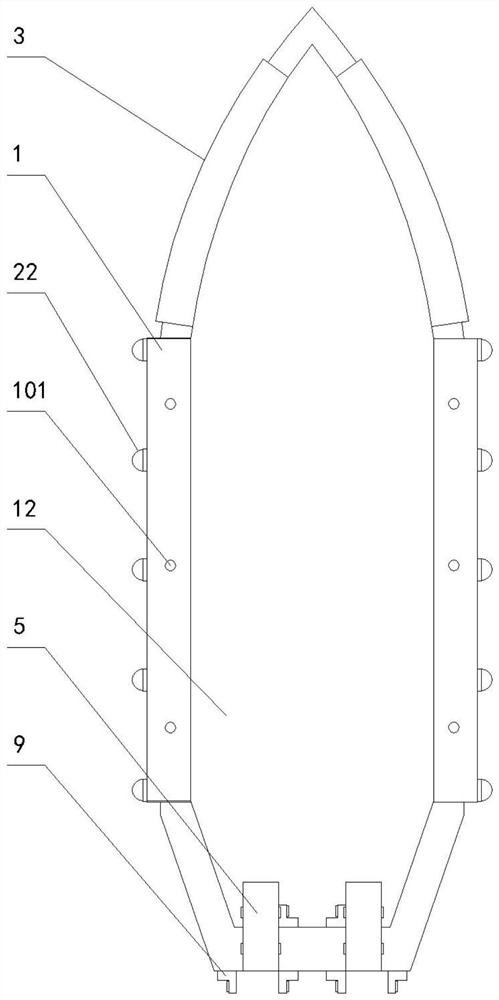

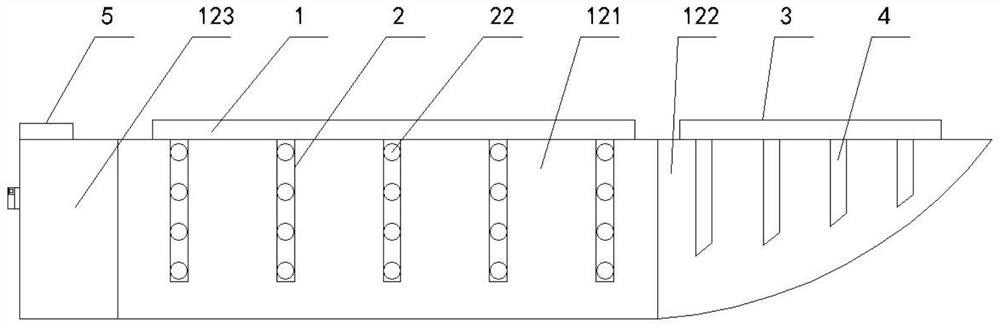

[0038] like figure 1 , figure 2 The hull protective structure of a fishing boat shown includes first protective plates arranged on the upper parts of both sides of the hull, a plurality of first protective strips arranged on the outside of both sides of the hull, and second protective plates arranged on the upper parts of both sides of the bow , a plurality of second protective strips arranged on both sides of the bow and a protective frame arranged at the stern,

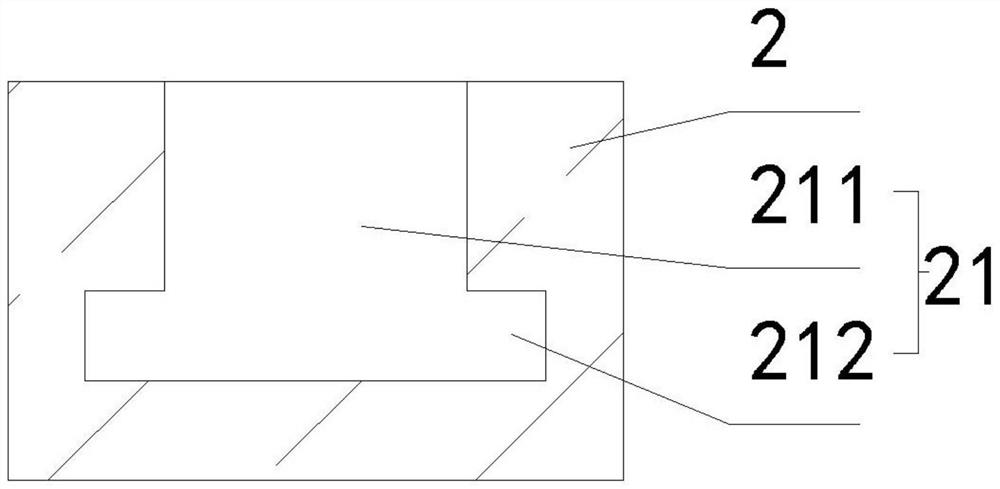

[0039] The first protective plate is horizontally and fixedly arranged on the hull, and a plurality of the first protective strips are arranged vertically in a strip shape and evenly distributed under the first protective plate. The first protective strips are arranged from top to bottom. A plurality of embedding grooves are vertically distributed, and a bullet block is embedded in the embedding groove, and the shape and size of the bottom of the bullet block correspond to the internal shape and size of the embedd...

Embodiment 2

[0051] Compared with embodiment 1, the differences of this embodiment are:

[0052] like Figure 12 As shown, the top of the fishing net salvage rack is provided with a square ring body, and the cross section of the square ring body is circular; both sides of the square ring body are fitted with a rolling ring, and the rolling ring and the square ring Bearings are arranged between the bodies, and rolling grooves are set on the side of the rolling ring. The fishing net passes through the square ring body, and the fishing net is salvaged with the fishing net fishing frame as the focus point. In the rolling groove, the rolling ring is rollingly connected with the square ring body when the fishing net rope is dragged.

[0053] The working process of the present invention:

[0054] (1) When the fishing boat is not in use, the protective frame is placed inside the stern, and the protective frame is fixed in the fishing boat through the connection structure between the protective f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com