Movable ship loader for automobile dumping

A ship loader, mobile technology, applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problems of large investment, dust, large land occupation, etc., and achieve the effect of reducing environmental damage, improving sanitary environment, and being flexible.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to understand the above-mentioned purpose, features and advantages of the present invention more clearly, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be noted that, in the case of no conflict, the embodiments of the present application and the features in the embodiments can be combined with each other.

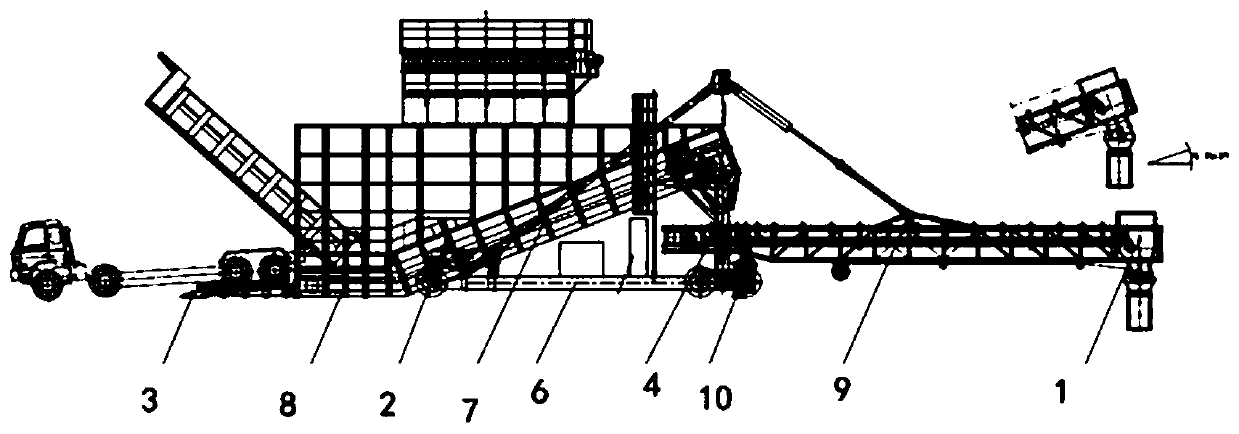

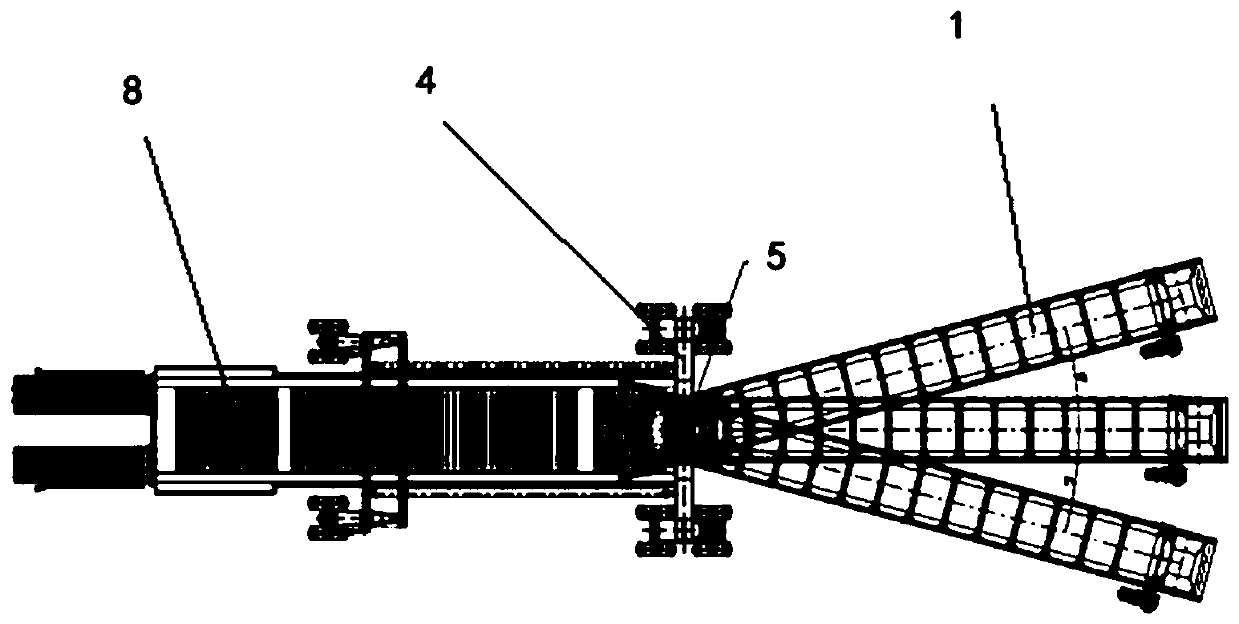

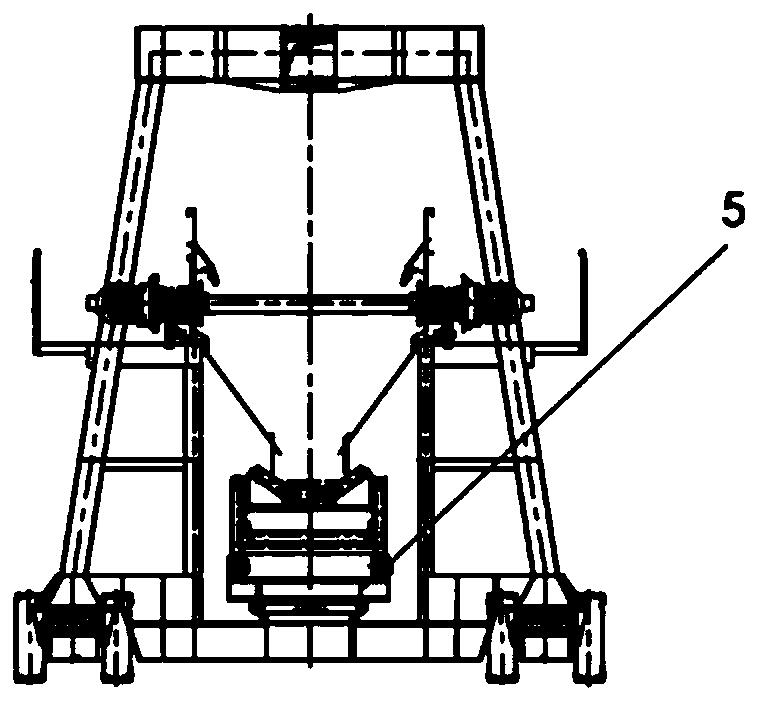

[0028] According to the mobile ship loader for automobile unloading according to the present invention, it includes a ship loader receiving section and a ship loader discharge section, a cart 2, and a dust removal device; a ship loader receiving section and a ship loader discharge section Both are connected with cart 2. The dust removal device is installed above the receiving section of the ship loader to control spillage when the dump truck is unloading. Preferably, the dust cover of the dust removal device is provided with spraying devices at the outlet and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com