Working face hydraulic bracket system machine following speed and hydraulic stability predicting method

A technology of hydraulic support and hydraulic system, which is used in mine roof support, earth-moving drilling, mining equipment, etc., can solve the problems of unquantifiable working face hydraulic support system with machine speed and hydraulic stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

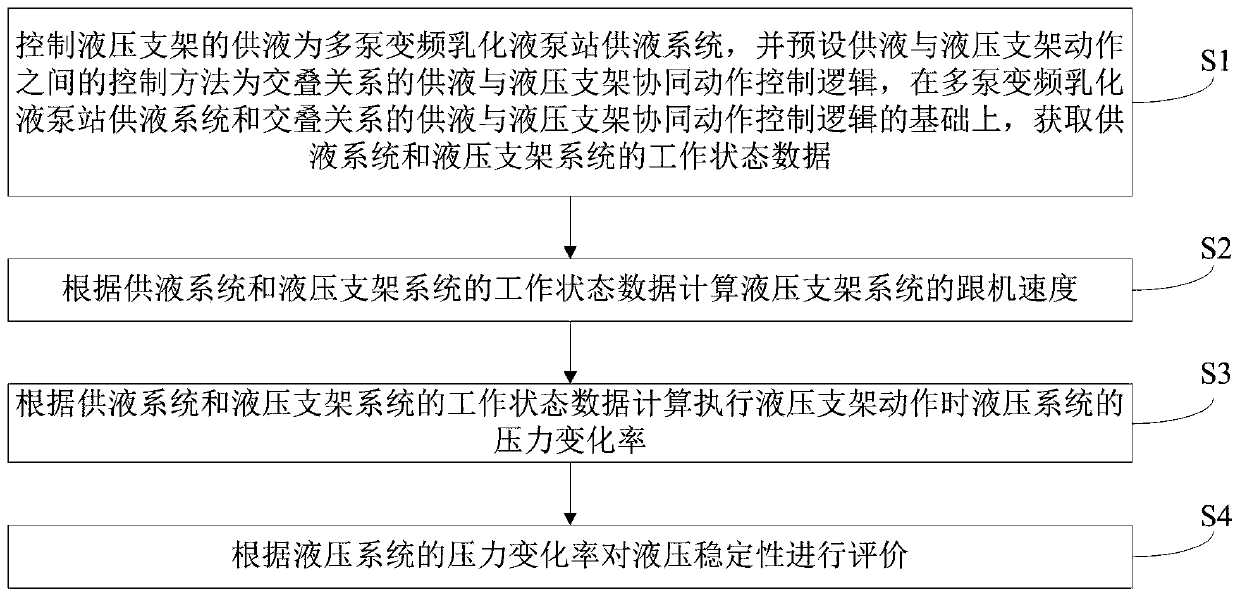

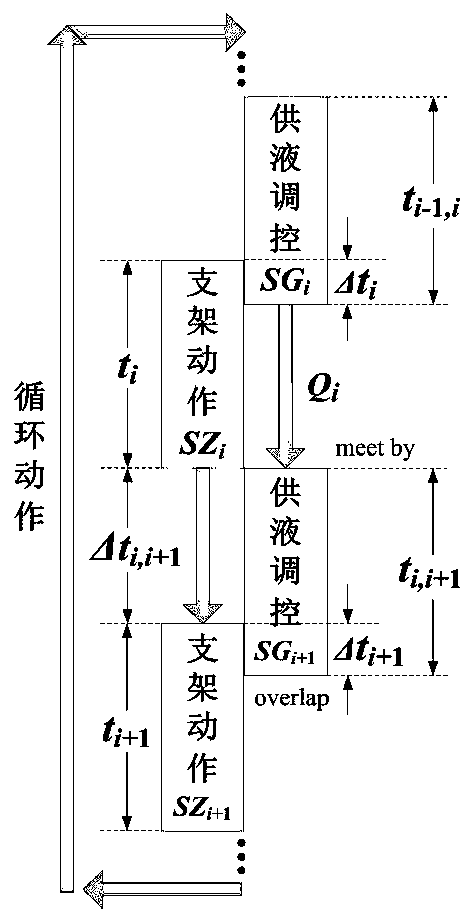

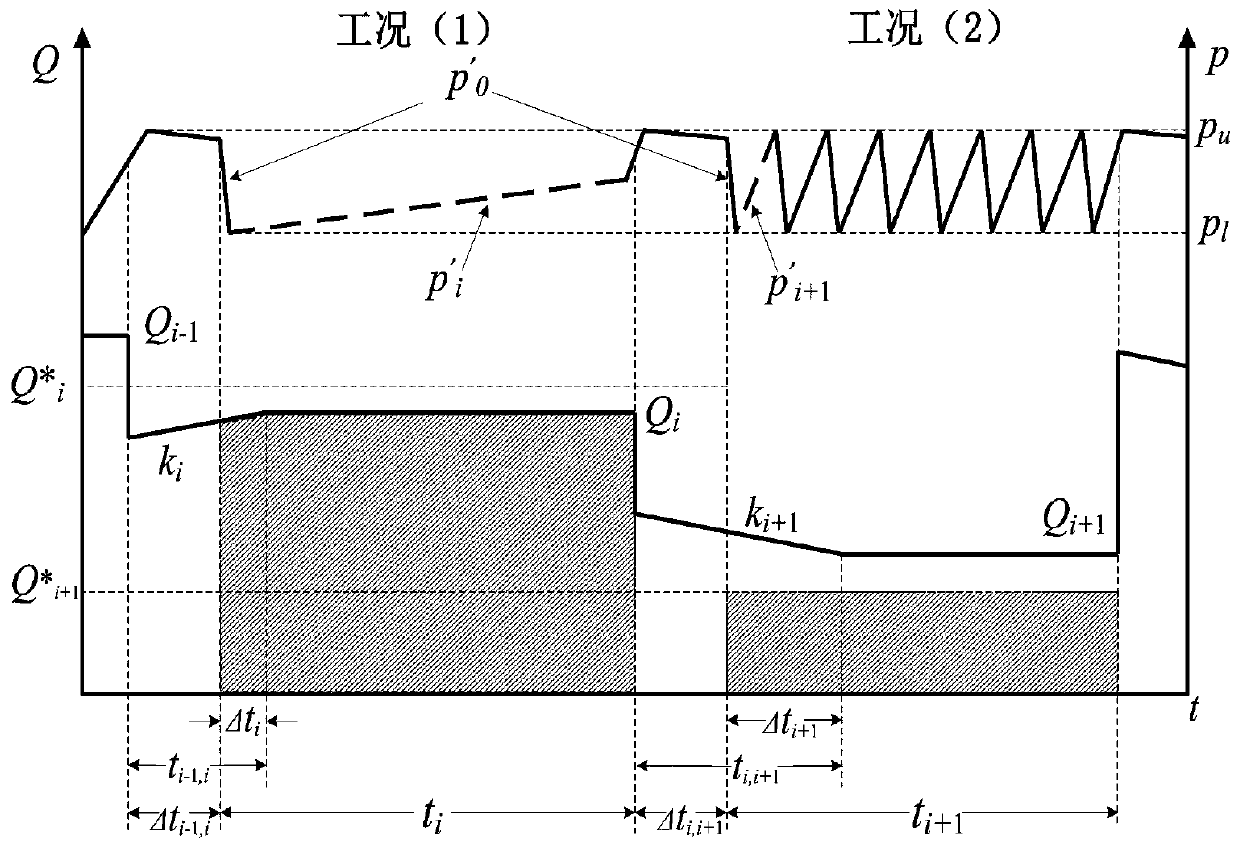

[0034] The follow-up speed of the hydraulic support system and the pressure stability of the hydraulic system are determined by the joint coupling of the hydraulic support follow-up control strategy and the hydraulic supply system control strategy. In view of this, under the premise of considering the control strategy of the hydraulic support with the machine, the present invention adopts the liquid supply system of the multi-pump frequency conversion emulsion pump station as the liquid supply power adjustment method, and based on the control method between the liquid supply and the hydraulic support action as the interactive Based on the control logic of the cooperative action of the hydraulic support system and the superimposed relationship, a method for predicting the follow-up speed and hydraulic stability of the hydraulic support system in the wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com