Vibration noise suppression device for three-phase AC motor

A three-phase AC, vibration and noise technology, used in electromechanical devices, electric components, cooling/ventilation devices, etc., can solve the problems of poor ventilation and heat dissipation of three-phase AC motors, affecting the service life of three-phase AC motors, and large vibration and noise. , to achieve the effect of ensuring ventilation and ventilation, improving ventilation and heat dissipation, and reducing noise decibels.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

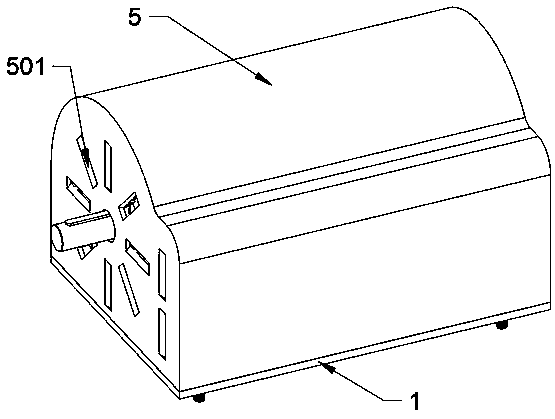

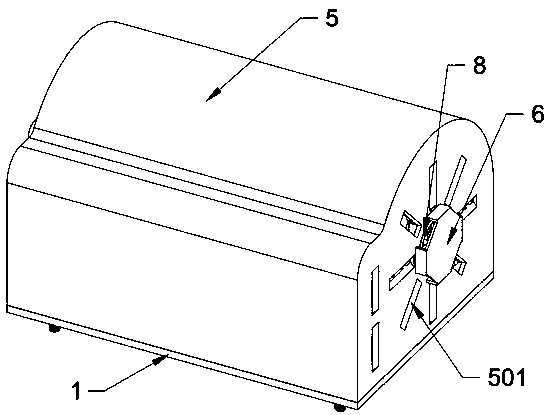

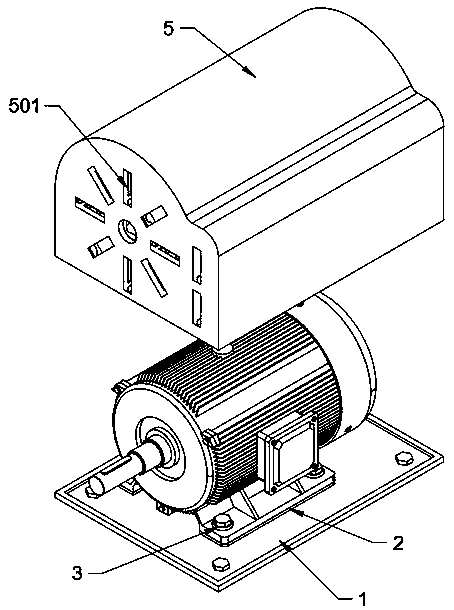

[0029] as attached figure 1 to the attached Figure 8 shown:

[0030] The present invention provides a vibration and noise suppression device for a three-phase AC motor, comprising a motor mounting plate 1, a rubber buffer pad 2, a rubber buffer pad 3, a mounting rubber strip 4, a noise reduction housing 5, a ventilation hole 501, a fan assembly hole 502, The sound insulation board 6, the sound-absorbing cotton 7 and the ventilation cooling fan 8; the motor mounting plate 1 is a rectangular plate-like structure, and the rubber buffer pad 2 and the mounting rubber strip 4 are respectively installed on the upper and lower sides of the motor mounting plate 1, and the three The phase AC motor is installed on the top end face of the motor mounting plate 1; the noise reduction housing 5 is an arc-shaped enclosure structure, and the noise reduction housing 5 is installed on the top end face of the motor mounting plate 1, and the three-phase AC motor is located in the noise reduction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com