Thermal superconducting plate and thermal superconducting heat sink

A thermal superconductivity and radiator technology, applied in the field of heat transfer, can solve problems such as equipment not working properly, plate-fin radiator failure, heat transfer working medium leakage, etc., to prevent equipment from working normally, ensure heat dissipation performance, ensure performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

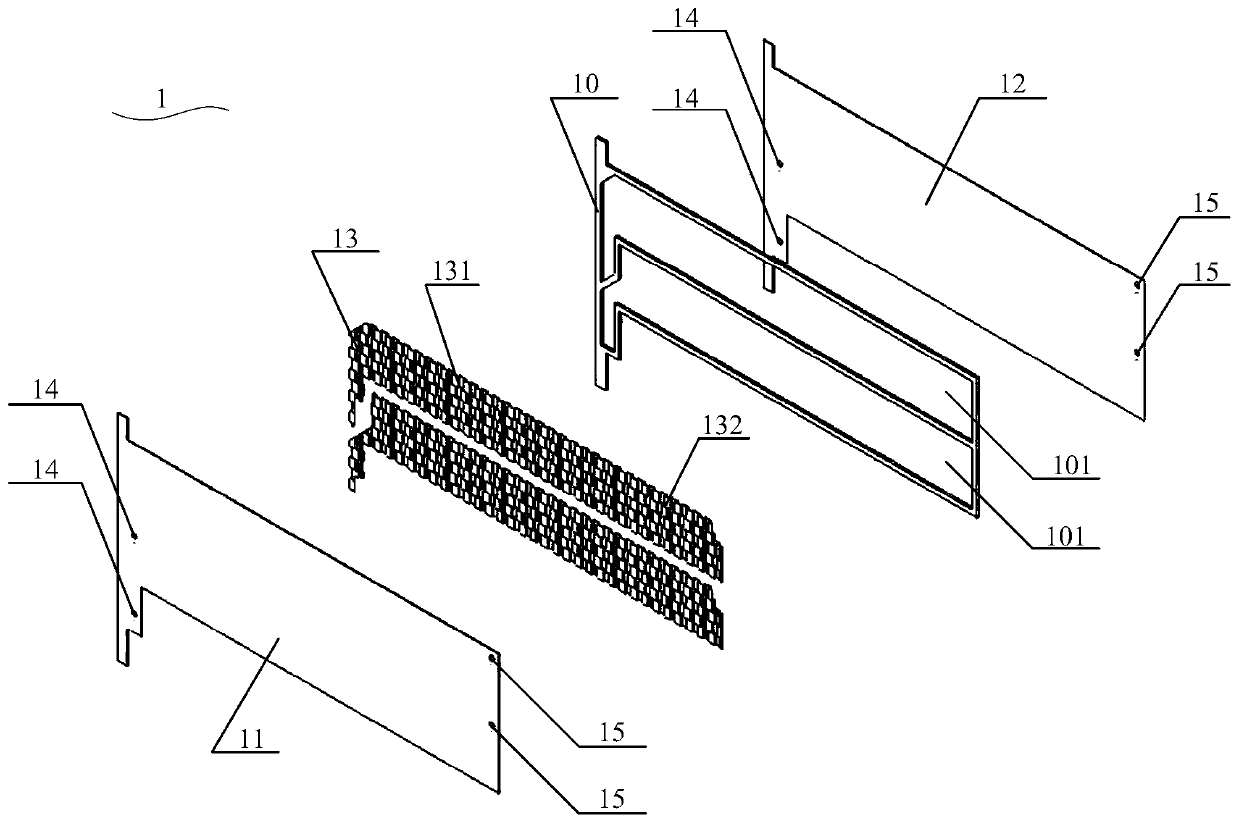

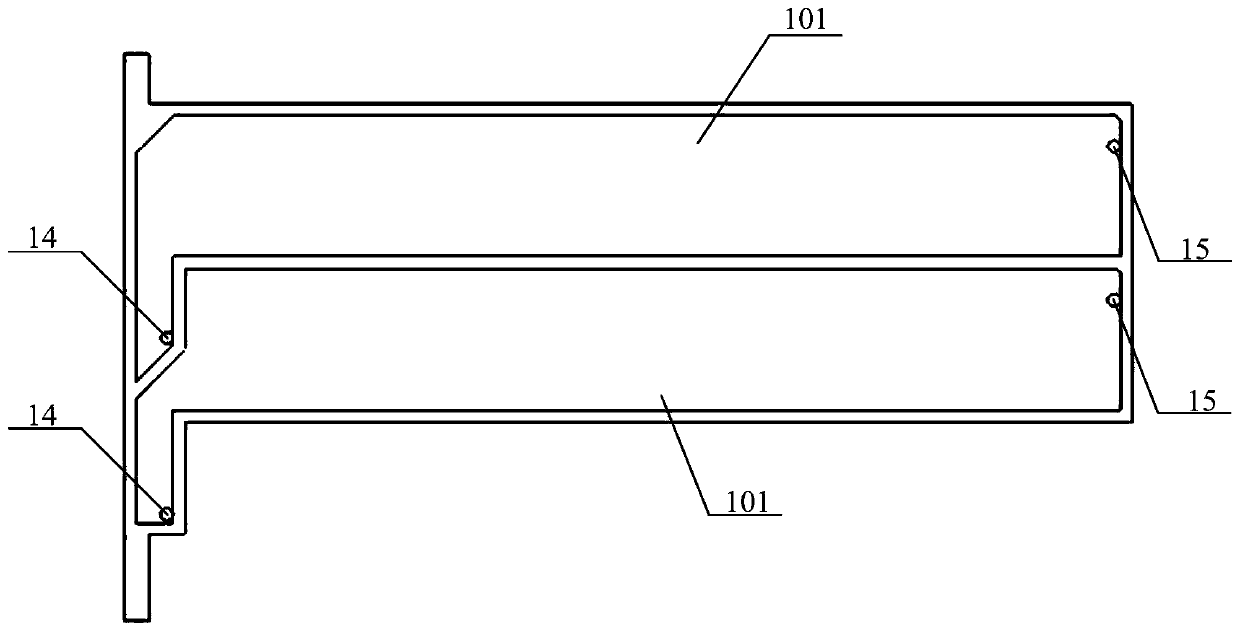

[0080] see Figure 1 to Figure 2 , the present invention provides a thermal superconducting plate 1, a plurality of mutually independent closed cavities (not shown) are formed in the thermal superconducting plate 1, and each of the closed cavities starts from the thermal superconducting plate One side of 1 extends to the opposite side, and each of the closed cavities is provided with a thermal superconducting heat transfer channel (not shown), and the thermal superconducting heat transfer channel is filled with a heat transfer working medium (where not marked). The thermal superconducting plate 1 of the present invention can form a plurality of mutually independent thermal superconducting heat transfer channels in the thermal superconducting plate 1 by arranging a plurality of mutually independent closed chambers inside, even if there is one The problem of leakage of the heat transfer working medium in the thermal superconducting heat transfer channel will not affect the norm...

Embodiment 2

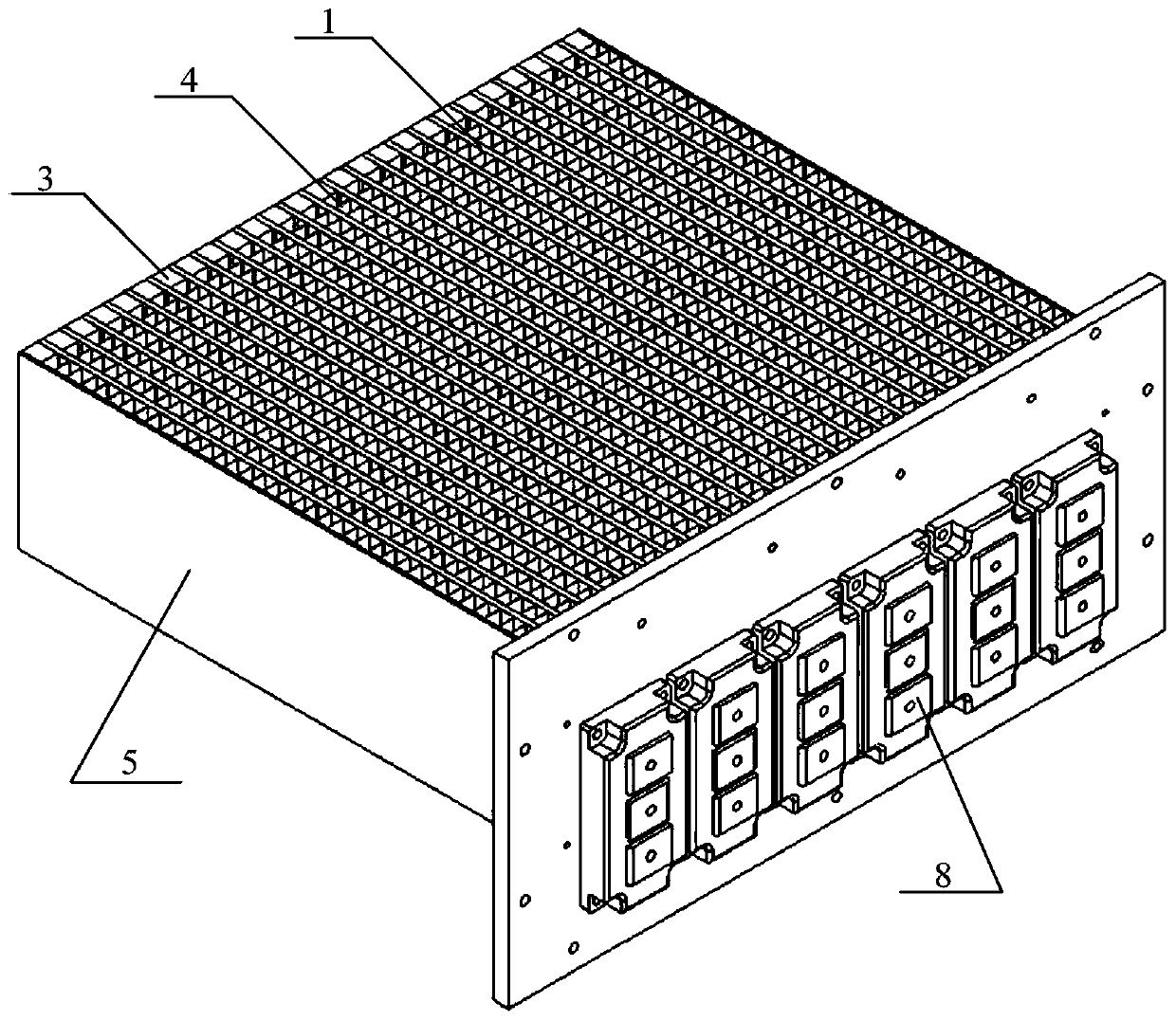

[0095] Please combine Figure 1 to Figure 2 refer to Figure 3 to Figure 6 , the present invention also provides a thermal superconducting radiator, the thermal superconducting radiator includes: a plurality of thermal superconducting plates 1 arranged at intervals, each of the thermal superconducting plates 1 is formed with a plurality of mutually independent Closed cavities (not shown), each of the closed cavities extends from one side of the thermal superconducting plate 1 to the opposite side, and each of the closed cavities is provided with a thermal superconducting heat transfer channel (not shown), the thermal superconducting heat transfer channel is filled with heat transfer working fluid (not shown); several first substrate spacers 2, the first substrate spacer 2 and the thermal superconductor The plates 1 are alternately arranged, and the first substrate spacers 2 are pasted on the surface of the thermal superconducting plate 1; several second substrate spacers 3, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com