Poly (cyclohexene carbonate) copolymer and preparation method thereof

A technology of polycyclohexenyl carbonate and copolymer, applied in the field of polycyclohexenyl carbonate copolymer and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

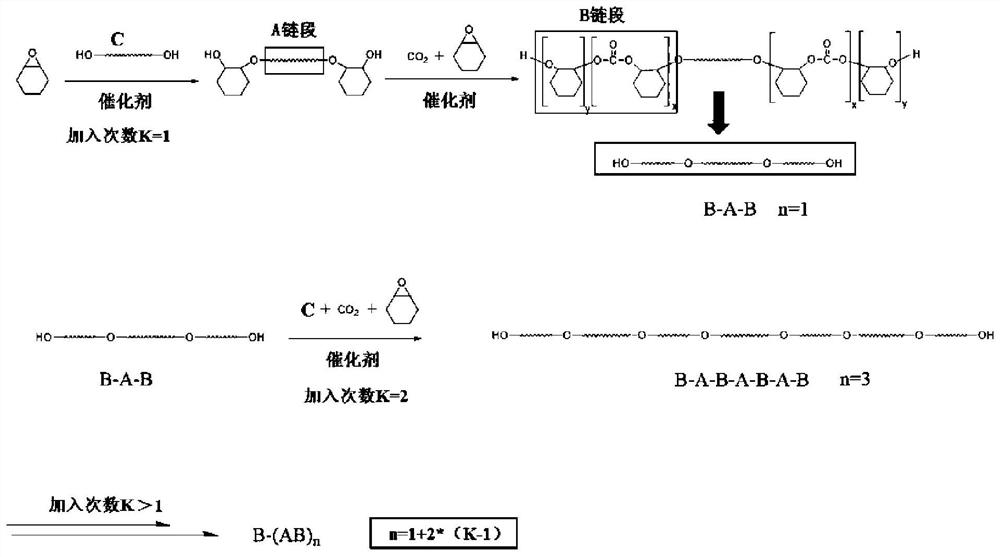

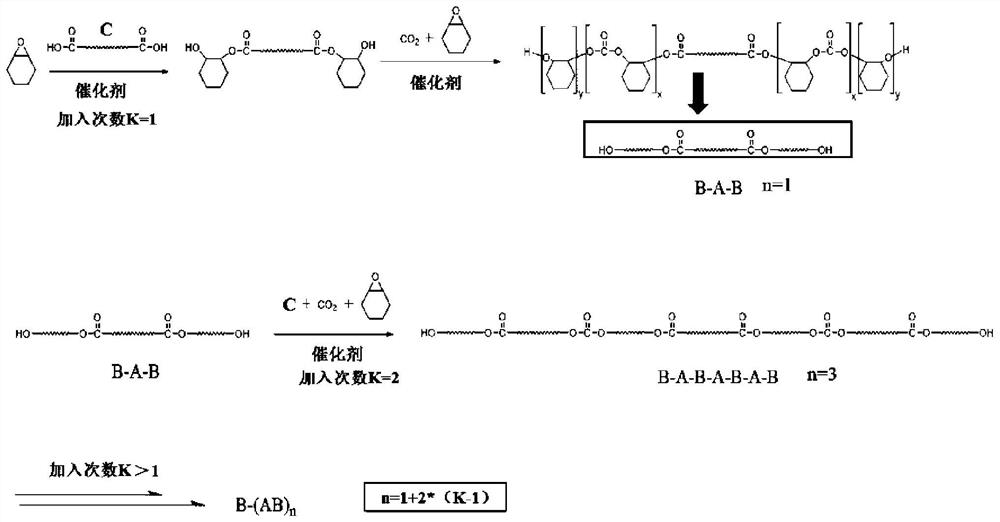

Method used

Image

Examples

Embodiment 1

[0059] A preparation method of a polycyclohexenyl carbonate copolymer, the specific preparation process is: in a 100ml high-pressure reactor after dehydration and deoxygenation, first add biocide with double-sided active ends at the initial stage of the reaction. Degraded aliphatic polyester C (polybutylene terephthalate-co-butylene adipate) (2 g, number average molecular weight 8000 g / mol, molecular weight distribution index 1.21), dried 1,2- Epoxycyclohexane (20ml), dry dioxolane (10ml) and Zn-Co double metal cyanide catalyst (5mg), fill into carbon dioxide in the autoclave by the carbon dioxide supply line with pressure regulating function again, make The pressure in the autoclave reached 5.0MPa, and the copolymerization reaction was carried out. After the copolymerization reaction, the autoclave was cooled to 25°C, and the carbon dioxide in the autoclave was slowly released. 1 H-NMR NMR sample for NMR measurement. The crude product was dissolved in dichloromethane, then p...

Embodiment 2

[0073] A preparation method of a polycyclohexenyl carbonate copolymer, the specific preparation process is: in a 50ml high-pressure reactor after dehydration and deoxygenation, firstly add a polycarbonate with active ends on both sides for the first time at the initial stage of the reaction Biodegrade aliphatic polyester C, 1,2-epoxycyclohexane, solvent and catalyst, and then fill the autoclave with carbon dioxide through the carbon dioxide supply line with pressure regulation function, so that the pressure in the autoclave reaches 5MPa, Carry out copolymerization reaction to synthesize the B segment to form a B-A-B type prepolymer; then continue to add biodegradable aliphatic polyester C with double-sided active ends to the reaction system for the second time; after the copolymerization reaction, cool the autoclave To 25 ℃, slowly let off the carbon dioxide in the high-pressure reactor, open the reactor as soon as possible to take 1 H-NMR NMR sample for NMR measurement. The ...

Embodiment 3

[0077] A preparation method of a polycyclohexenyl carbonate copolymer, the specific preparation process is: in the 100ml high-pressure reactor after dehydration and deoxygenation, firstly add the polycarbonate with active ends on both sides for the first time at the initial stage of the reaction Biodegrade aliphatic polyester C, 1,2-epoxycyclohexane, solvent and catalyst, and then fill the autoclave with carbon dioxide through the carbon dioxide supply line with pressure regulation function, so that the pressure in the autoclave reaches 4MPa, Carry out copolymerization reaction to synthesize the B segment to form a B-A-B type prepolymer; then continue to add biodegradable aliphatic polyester C with double-sided active ends to the reaction system in 2 times; after the copolymerization reaction, cool the high-pressure reactor To 25 ℃, slowly let off the carbon dioxide in the high-pressure reactor, open the reactor as soon as possible to take 1 H-NMR NMR sample for NMR measuremen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com