Tailless aircraft

A technology of aircraft and wings, applied in the field of controlling aircraft during flight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

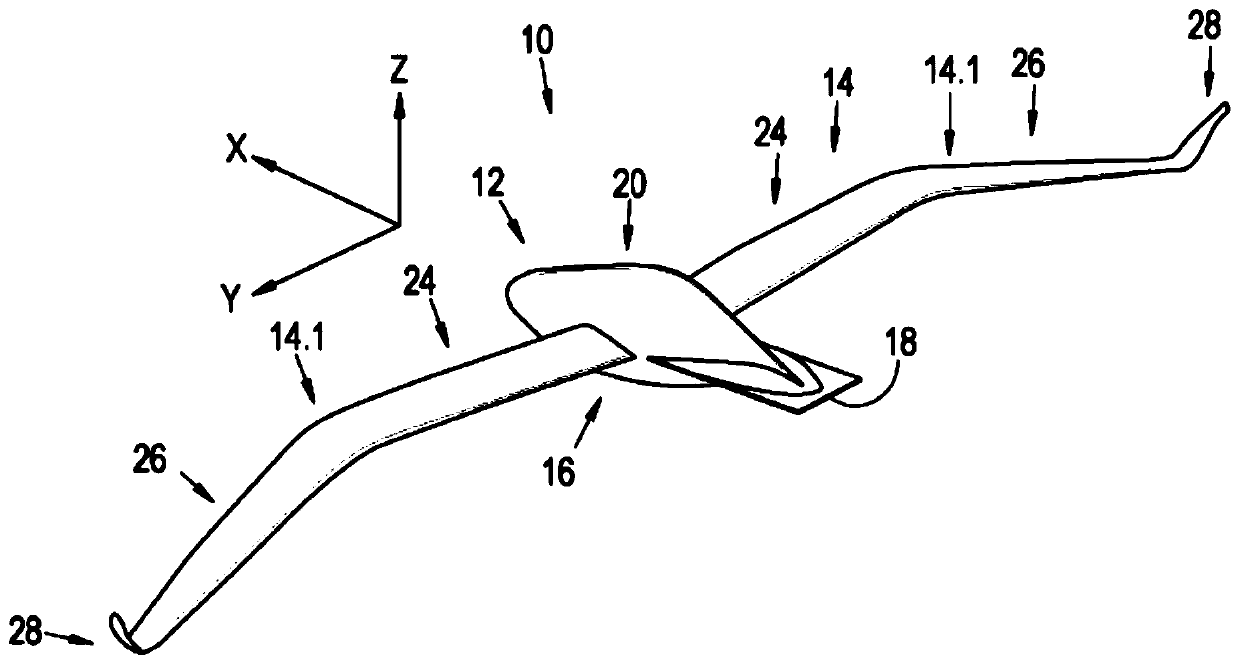

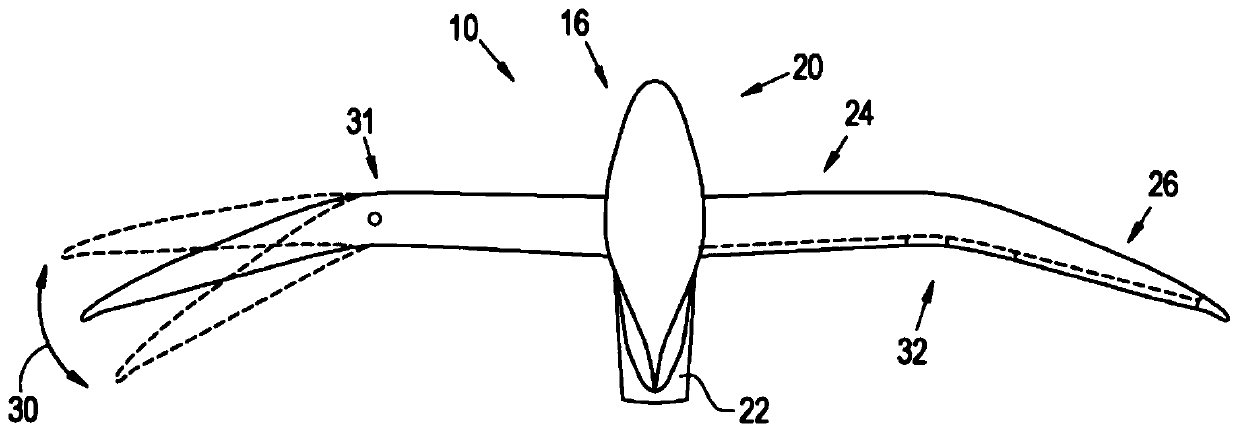

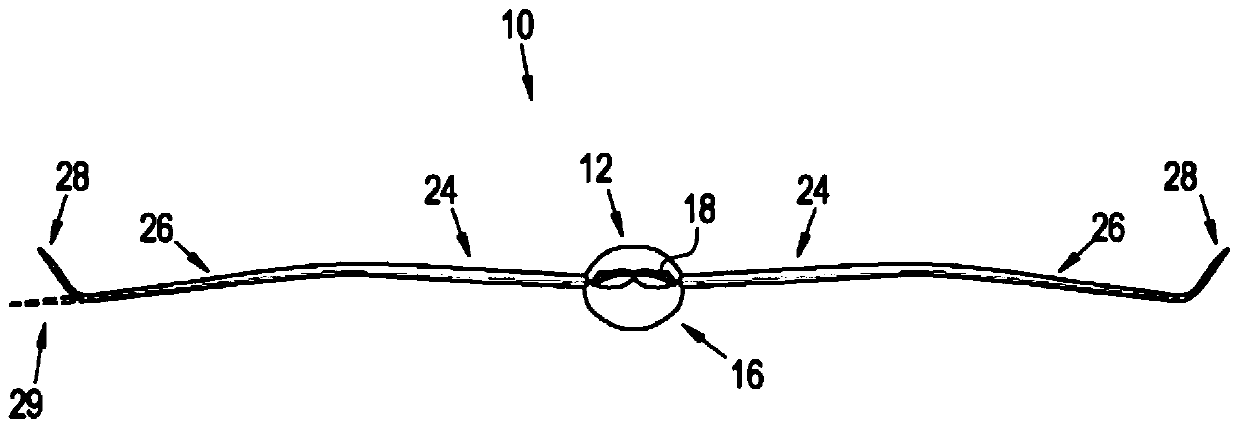

[0050]In the figures, reference numeral 10 generally refers to an aircraft according to the invention. Aircraft 10 includes a tailless fuselage, generally indicated by reference numeral 12 , and a wing 14 having two sides 14 . 1 connected to fuselage 12 and extending laterally from opposite sides of fuselage 12 .

[0051] Fuselage 12 includes an airframe generally indicated by reference numeral 16 , terminating in a transverse trailing edge 18 . In particular, the airframe 16 includes a hollow, bulbous main portion generally indicated by the reference numeral 20 and flaps 22 projecting rearwardly from the main portion 20 and forming the trailing edge 18 . relative to the attached figure 1 The vertical X, Y and Z axes shown in , when the aircraft 10 is intended to fly in the direction of the X-axis, the trailing edge 18 generally extends laterally in the direction of the Y-axis, ie, generally perpendicular to the direction of flight X. The position of the flap 22 relative to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com