Coal screening device and using method thereof

A screening device and coal technology, applied in chemical instruments and methods, sieves, solid separation, etc., can solve the problems of easy clogging of sieve holes, wear of hammer heads, and large maintenance, so as to improve screening efficiency and increase coal production. The effect of low circulation and manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

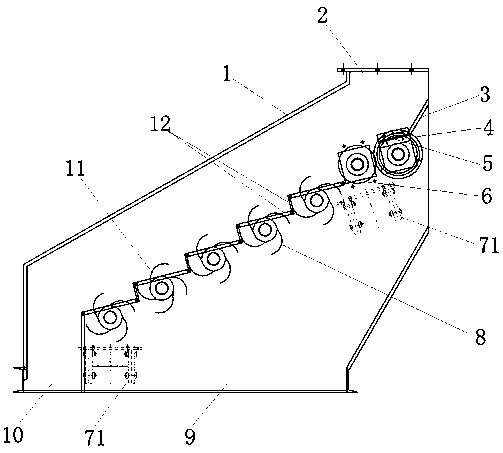

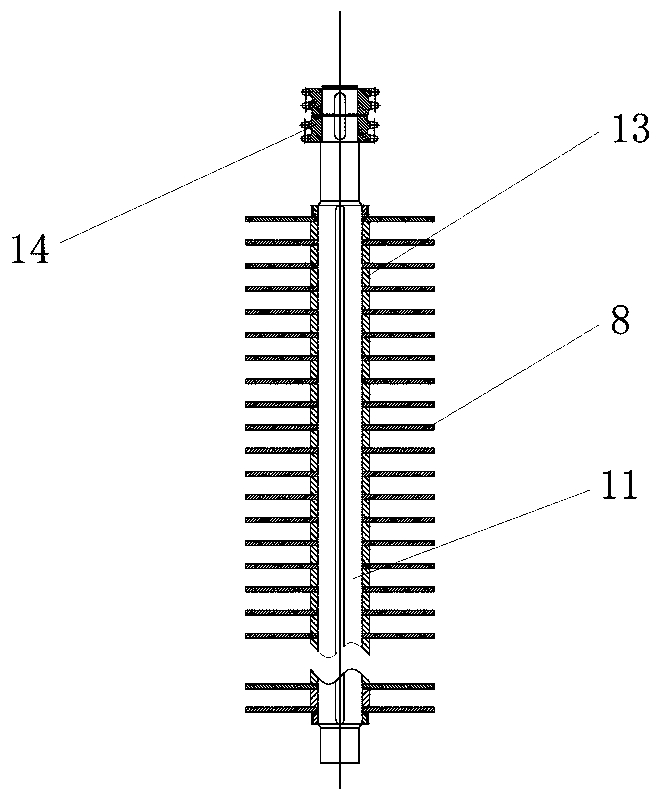

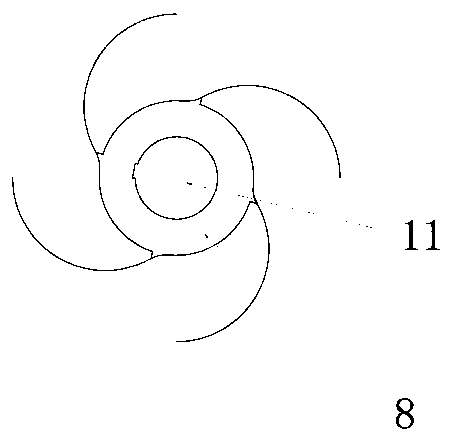

[0025] Such as figure 1 , 2 , 3, and 4, the coal screening device of the present invention comprises a housing 1, one side of the top of the housing is provided with a feed inlet 2, and the bottom is provided with small and large particle discharge ports 9,10; the housing 1 There is a stepped sieve plate 12 extending obliquely from the side of the feed port 2 to the direction of the large particle discharge port 10. The stepped sieve plate 12 passes through a plurality of sieve bars and spliced longitudinally to form a sieve plate. The stepped planes are combined and connected to form an inclined ladder; the lower side of the feed port 2 is provided with a baffle 3 for guiding, and the baffle 3 extends to the first-stage feed buffer rotary screen roller 4 and the second-stage feed buffer rotary screen. On the upper side of the sieve roller 6, the uppermost end of the stepped sieve plate 12 is connected to the lower side of the secondary feed buffer rotary sieve roller 6, wh...

Embodiment 2

[0034] The inventive device of the present embodiment comprises a housing 1, one side of the top of the housing 1 is provided with a feed inlet 2, and the bottom is provided with small and large particle discharge outlets 9, 10; 2 The stepped sieve plate 12 extending obliquely towards the large particle discharge port 10; the stepped sieve plate 12 is spliced longitudinally by a plurality of sieve bars side by side to form a sieve plate, and is connected by a combination of a stepped facade and a stepped plane to form an inclined ladder shape; the lower side of the feed port 2 is provided with a baffle 3 for guiding, and the baffle 3 extends to the upper side of the first-level feed buffer rotary sieve roller 4 and the second-stage feed buffer rotary sieve roller 6, and the steps The uppermost end of the shaped sieve plate 12 is connected to the lower side of the secondary feed buffer rotary screen roller 6, and is used to receive the coal that is buffered and pushed down fro...

Embodiment 3

[0039] The inventive device of the present embodiment comprises a housing 1, one side of the top of the housing 1 is provided with a feed inlet 2, and the bottom is provided with small and large particle discharge outlets 9, 10; 2 The stepped sieve plate 12 extending obliquely towards the large particle discharge port 10; the stepped sieve plate 12 is spliced longitudinally by a plurality of sieve bars side by side to form a sieve plate, and is connected by a combination of a stepped facade and a stepped plane to form an inclined ladder shape; the lower side of the feed port 2 is provided with a baffle 3 for guiding, and the baffle 3 extends to the upper side of the first-level feed buffer rotary sieve roller 4 and the second-stage feed buffer rotary sieve roller 6, and the steps The uppermost end of the shaped sieve plate 12 is connected to the lower side of the secondary feed buffer rotary screen roller 6, and is used to receive the coal that is buffered and pushed down fro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com