Cooling cover used before spinning of hub

A cooling cover and hub technology, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve problems such as deformation of supporting parts, easy deformation of hubs, and processing failure, so as to avoid obstacles, be easy to operate, and reduce occupied space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

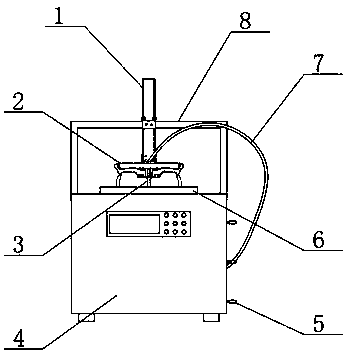

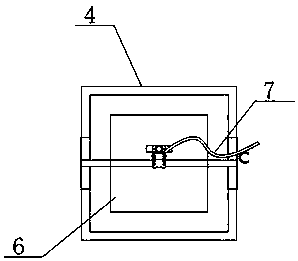

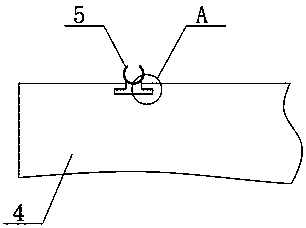

[0022] see figure 1 and figure 2 , the present invention provides a technical solution: a cooling cover before hub spinning, including a body 4, the top of the body 4 is provided with a bracket 8 in a C-shaped structure, and the two ends of the bracket 8 are fixed on the top edge of the slide rail 1 , the middle position of the surface of the support 8 is fixed with a slide rail 1, the surface of the slide rail 1 is provided with a clamping part that can slide up and down, the surface of the clamping part is fixed with a water outlet tray 2, the water outlet tray 2 is a cylindrical structure, and the water outlet The bottom surface of the disc 2 is uniformly provided with a plurality of water outlet holes, the diameter of the water outlet disc 2 is three-quarters of the diameter of the hub to be processed, and a cooling water tank is placed at the inner bottom of the body 4, and the connection between the water outlet disc 2 and the cooling water tank There are cooling water...

Embodiment 2

[0024] see Figure 1-Figure 4 , the present invention provides a technical solution: a cooling cover before hub spinning, including a body 4, the top of the body 4 is provided with a bracket 8 in a C-shaped structure, and the two ends of the bracket 8 are fixed on the top edge of the slide rail 1 , the middle position of the surface of the support 8 is fixed with a slide rail 1, the surface of the slide rail 1 is provided with a clamping part that can slide up and down, the surface of the clamping part is fixed with a water outlet tray 2, the water outlet tray 2 is a cylindrical structure, and the water outlet The bottom surface of the disc 2 is uniformly provided with a plurality of water outlet holes, the diameter of the water outlet disc 2 is three-quarters of the diameter of the hub to be processed, and a cooling water tank is placed at the inner bottom of the body 4, and the connection between the water outlet disc 2 and the cooling water tank There are cooling water pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com