Method for adjusting multi-angle butt joint of pipelines

A multi-angle, pipeline technology, applied in the direction of tubular objects, welding equipment, auxiliary welding equipment, etc., can solve the problems of large pipeline errors, waste of resources, waste of manpower, etc., and achieve the effect of saving time, resources and manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

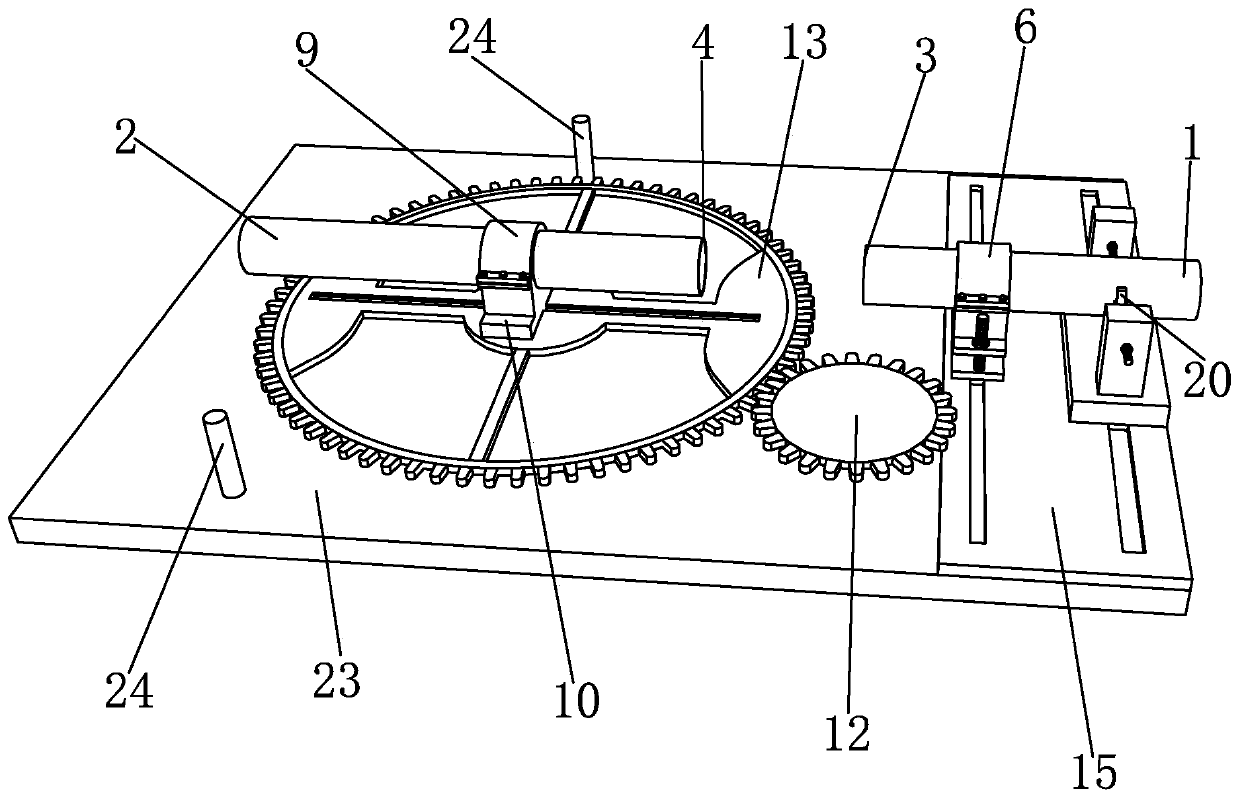

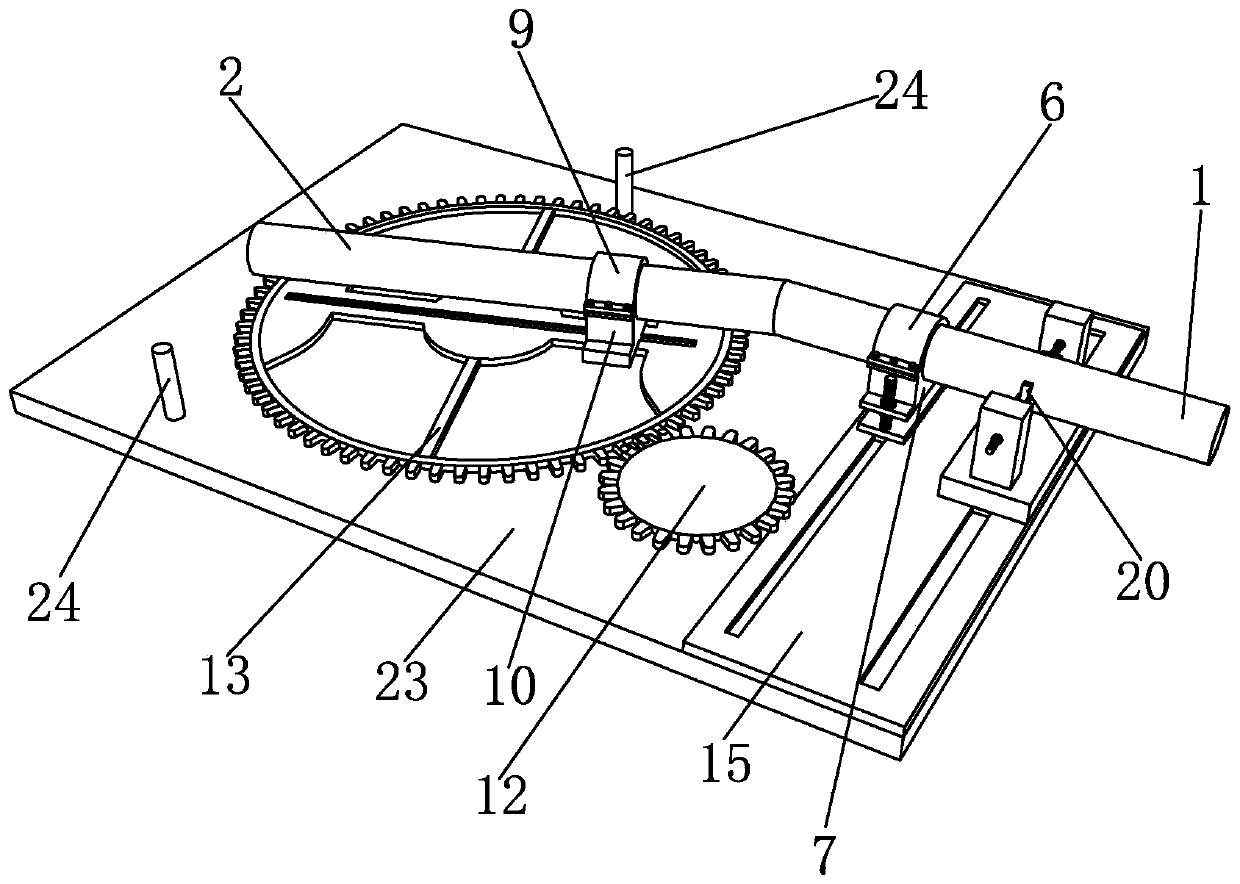

[0043] Such as Figure 1 to Figure 6 As shown, it is a method for multi-angle butt joint of adjustable pipelines of the present invention, comprising the following steps:

[0044] a. Preparation before docking

[0045] According to the requirements, first calculate the angle that needs to be connected to the pipeline, and clean the first pipeline connection interface 3 and the second pipeline connection interface 4.

[0046] b. Pipe clamping

[0047] 1) Clamping of the first pipeline 1

[0048] Unscrew the first threaded rod 5, turn off the first limit cap 6, put the first pipe 1 on the first pipe support 7, turn the first limit cap 6, clamp the first pipe 1, and tighten the first thread pole 5.

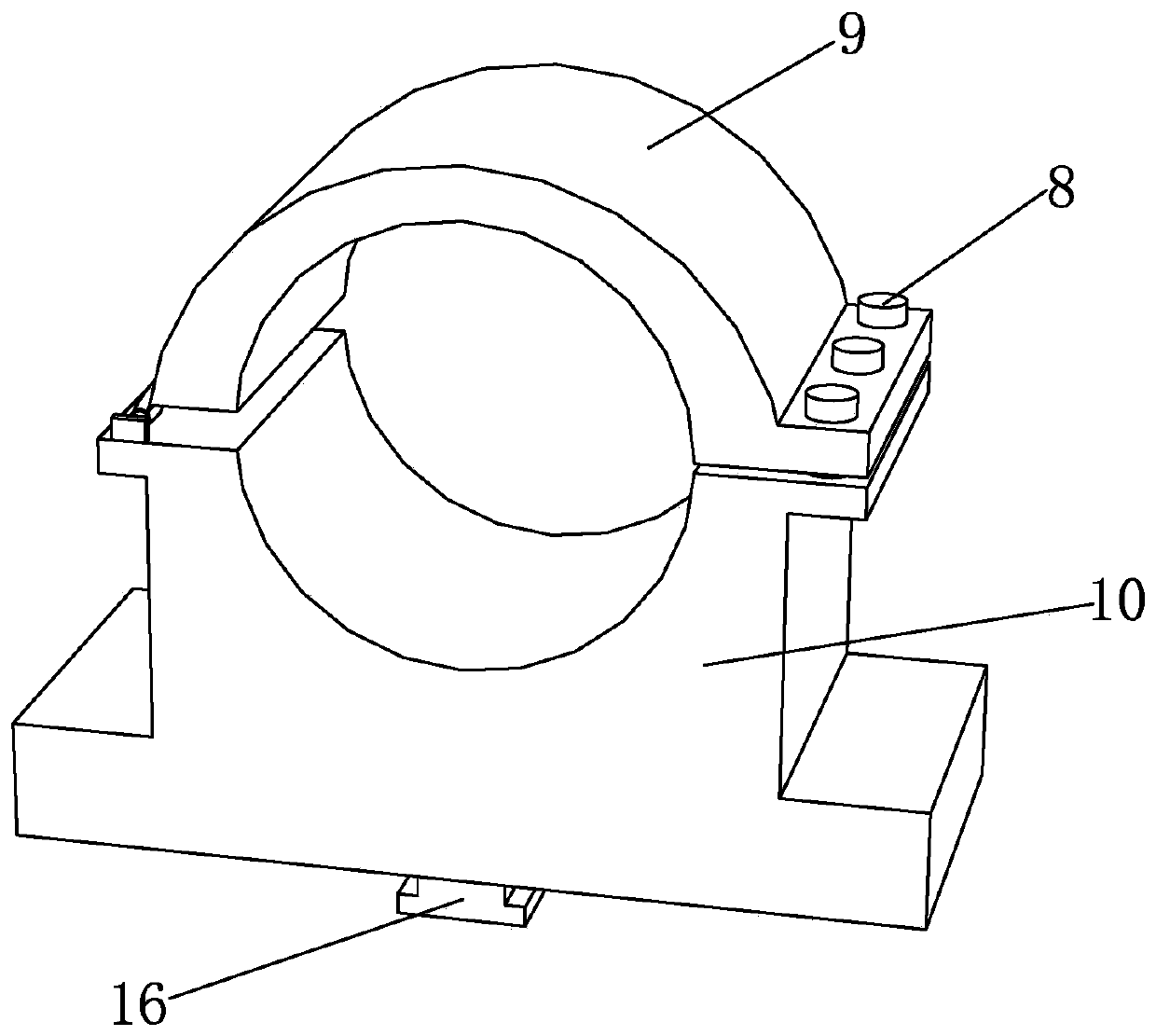

[0049] 2) Clamping of the second pipeline 2

[0050] Unscrew the second threaded rod 8, turn off the second limit cap 9, put the second pipe 2 on the second pipe support 10, turn the second limit cap 9, clamp the second pipe 2, and tighten the second thread pole 8.

[0051] c....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com