Multifunctional integrated forging device

An all-in-one, multi-functional technology, applied in the direction of manufacturing tools, transportation and packaging, other manufacturing equipment/tools, etc., can solve the problems of applicability and practicality limitations, affecting the efficiency of processing, waste costs, etc., to achieve effective and rapid Forging processing, reasonable structure setting, convenient operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

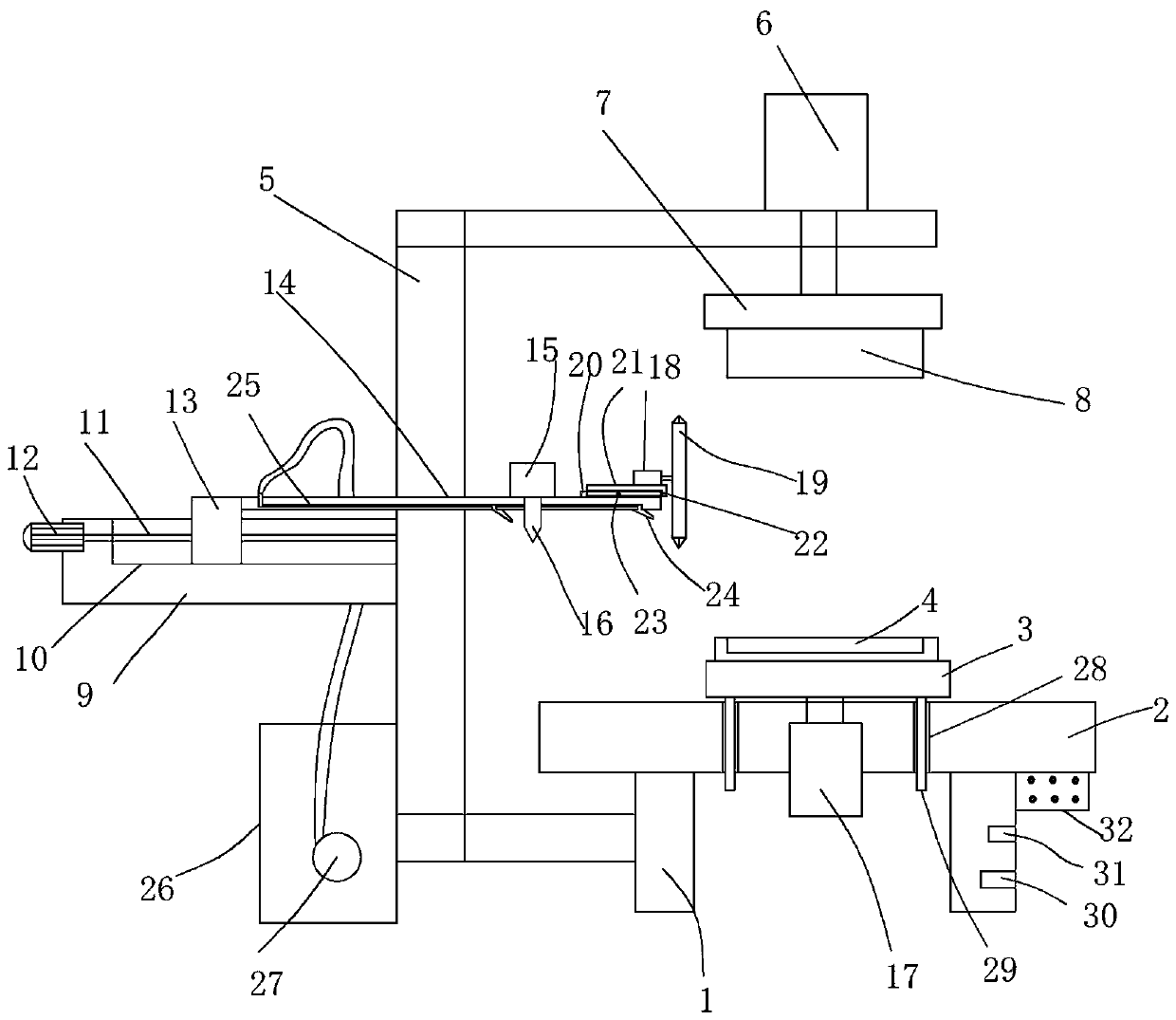

[0015] figure 1 A specific embodiment of the invention is shown in which figure 1 It is a structural schematic diagram of the present invention.

[0016] See figure 1 , a multi-functional integrated forging device, comprising a bracket 1, a forging platform 2 fixed on the bracket, a lower die base 3 is arranged on the top of the forging platform, and a forging base is fixed on the top of the lower die base The lower mold 4 is fixed with a support frame 5 on the support, a forging hydraulic cylinder 6 is fixed on the support frame, and an upper mold base 7 is fixed on the piston shaft of the forging hydraulic cylinder. The bottom surface of the seat is fixed with a forging upper mold 8, and a translation protrusion 9 is arranged on the support frame, and a translation chute 10 is opened on the translation protrusion, and the translation chute is arranged on the upper mold base and the lower mold. Between the seats, a ball screw 11 is arranged in the translation chute, and a ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap