Special grinding device for spherical object

A technology of spherical objects and sound insulation devices, which is applied in the field of PLC control, can solve the problems of high noise, increased difficulty of grinding, and not easy to fix, so as to achieve the effect of increasing anti-skid performance and increasing the grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

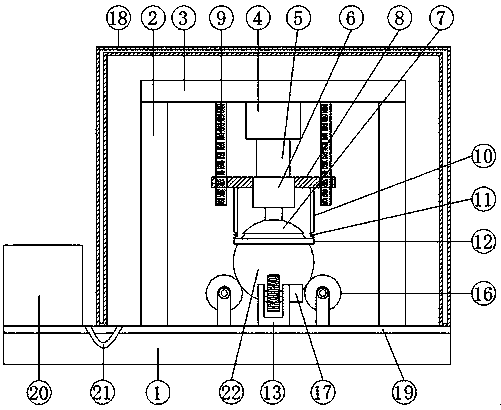

[0031] see Figure 1-4 According to an embodiment of the present invention, a special grinding device for spherical objects includes a workbench 1. The workbench 1 mainly provides a support frame assembly, a grinding device, a supporting device, a sound insulation assembly and a PLC controller 20 to prevent For the function of the table, a supporting frame device is arranged on the workbench 1, a grinding device is arranged under the supporting frame device, a supporting device is arranged below the polishing device, and a sound insulation device and a PLC controller 20 are arranged on the workbench 1.

[0032] Let's talk about the specific settings and functions of the support frame assembly, the grinding device, the supporting device, the sound insulation assembly and the PLC controller 20 in detail.

[0033] The support frame device includes two support arms 2, the support arms 2 are respectively fixed on both sides of the workbench 1, and the upper end of the support arm 2...

Embodiment 2

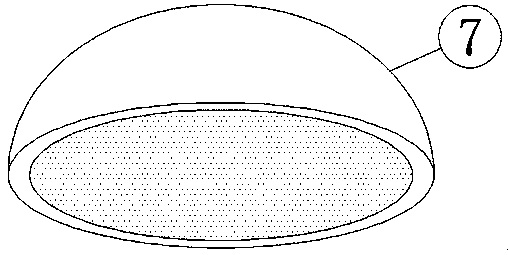

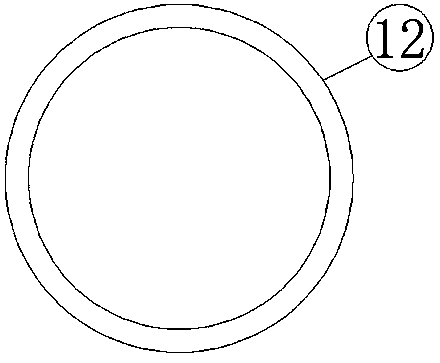

[0039] see Figure 1-4 , for the arc-shaped grinding sheet 17, the interior of the arc-shaped grinding sheet 7 is processed with frosted lines, which can increase the grinding effect of the arc-shaped grinding sheet 17; for the supporting wheel 16, the outer wall of the supporting wheel 16 is provided with anti-slip lines, Can increase the anti-skid performance of supporting wheel 16; For vacuum interlayer cover 18, vacuum interlayer cover 18 is made of tempered glass plate with vacuum interlayer, can stop the noise that grinding produces to pass through vacuum interlayer cover 18; For workbench 1, the workbench 1 is provided with a line hole 21, and the two ports of the line hole 21 are respectively arranged on both sides of the side wall of the vacuum interlayer cover 18, so that the wires in the vacuum interlayer cover 18 can pass through the line hole 21 and communicate with the PLC controller. 20 for electrical connection.

[0040] To sum up, with the help of the above t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com