High-frequency shearing light curing three-dimensional forming device and method

A three-dimensional forming and photocuring technology, applied in the directions of additive manufacturing, processing and manufacturing, and auxiliary operation of additional layers, etc., can solve the problems of high cost of the bottom plane of the liquid tank, less types of photosensitive resins, and reduced peeling speed, etc. High frequency stability, no peeling damage, and the effect of flat peeling damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

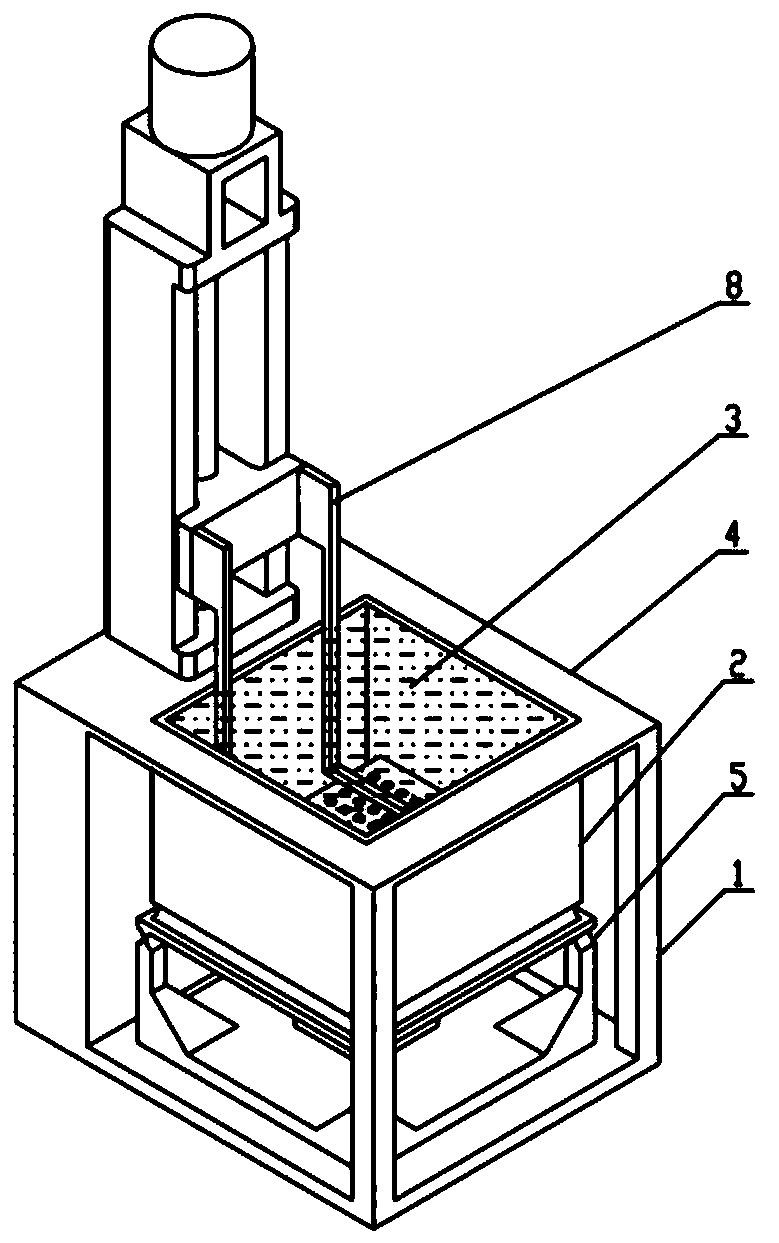

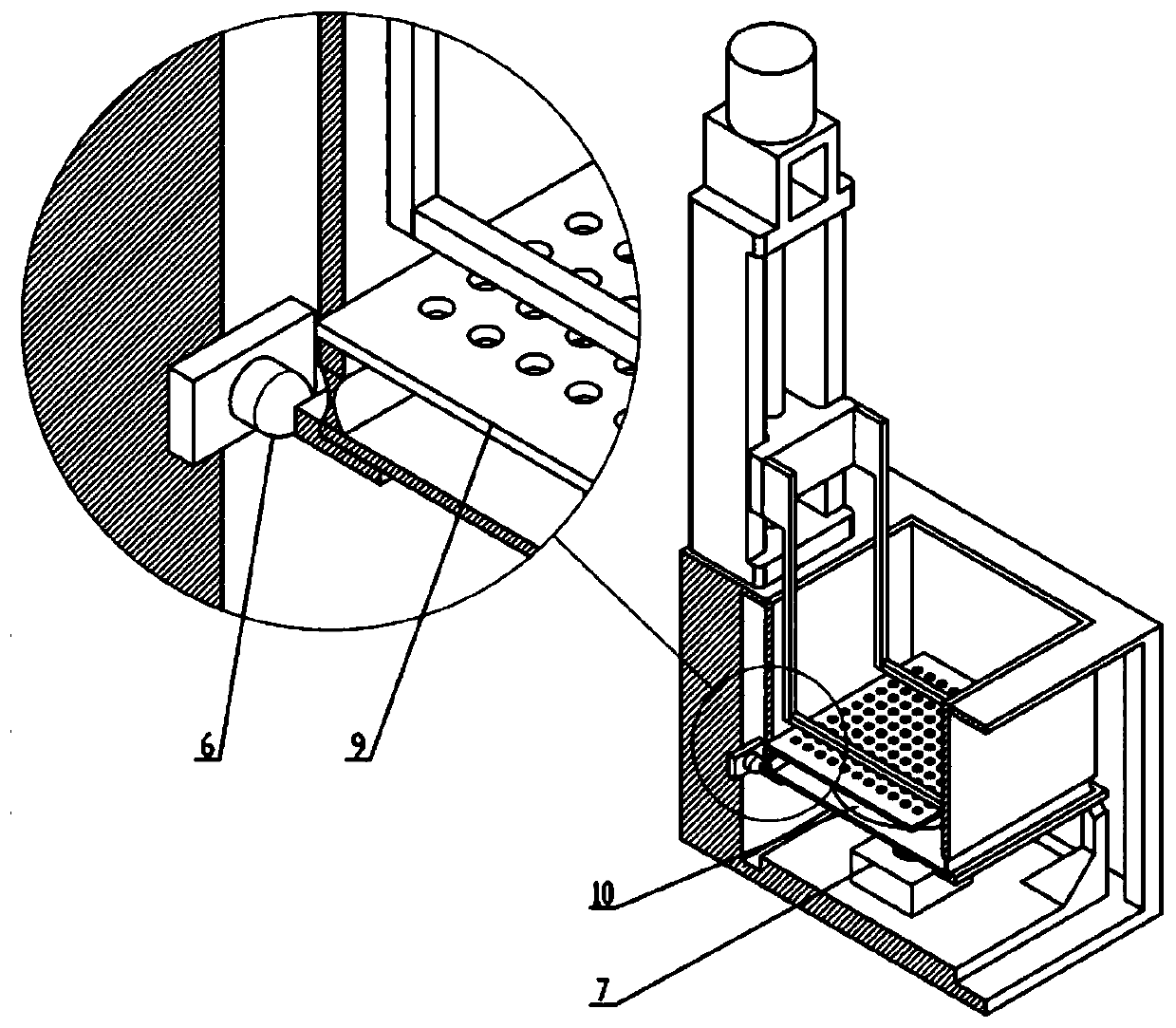

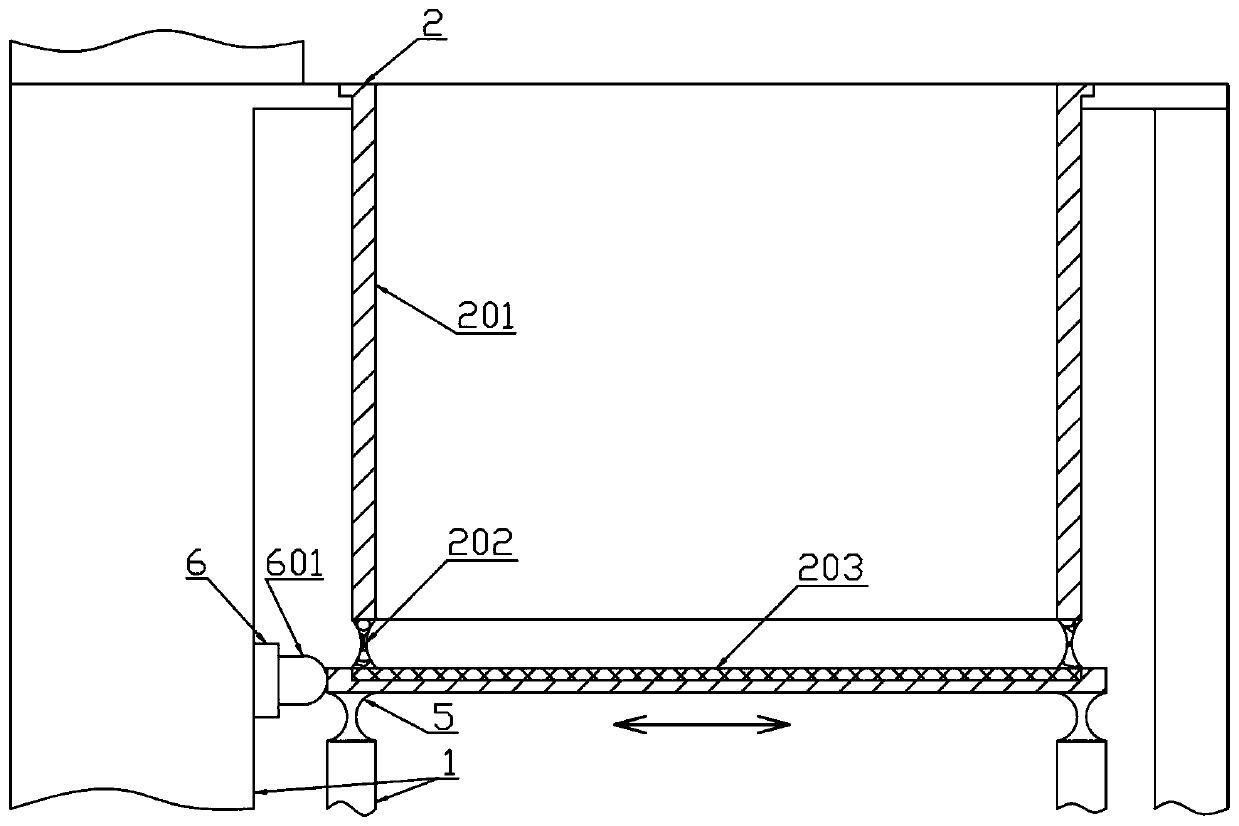

[0025] A high-frequency shear light curing three-dimensional forming device, such as figure 1 , 2, there is a liquid tank 2 in the rigid frame 1, and there is a photosensitive polymer material 3 in the liquid tank 2, and the opening of the liquid tank 2 is fitted on the top plate 4 of the rigid frame 1; there is an elastic guide rail 5 at the bottom of the rigid frame 2, and the movement of the elastic guide rail 5 The platform is connected to the bottom of the liquid tank 2; the inner surface of the rigid frame 2 has a high-frequency vibrator 6, and the actuating rod of the high-frequency vibrator 6 is connected to the bottom side of the liquid tank 2; the bottom of the rigid frame 2 has an imaging element 7, and the imaging element 7 can The optical pattern is projected onto the bottom of the liquid tank 2, and after the optical pattern penetrates the bottom of the liquid tank 2, it exposes the photosensitive polymer material 3 on the liquid surface under the liquid tank 2; ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap