An integrated thermal insulation board with decorative function

An insulation board and integrated technology, which is applied in the field of insulation board materials, can solve the problems of unsatisfactory insulation performance, monotonous material color, and insufficient aesthetics of insulation boards, so as to improve aesthetics, improve thermal insulation and flame retardancy, and prevent cracking. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

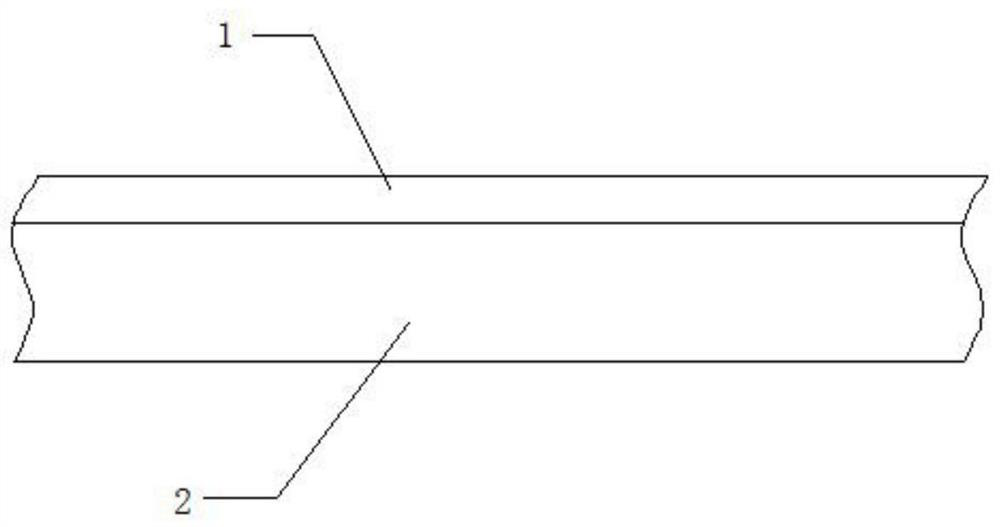

[0057] see figure 1 and figure 2, an integrated thermal insulation board with a decorative function, comprising 2 main materials of the thermal insulation board, 2 auxiliary materials of the thermal insulation board, 1 main material of the decorative board, and 1 auxiliary material of the decorative board;

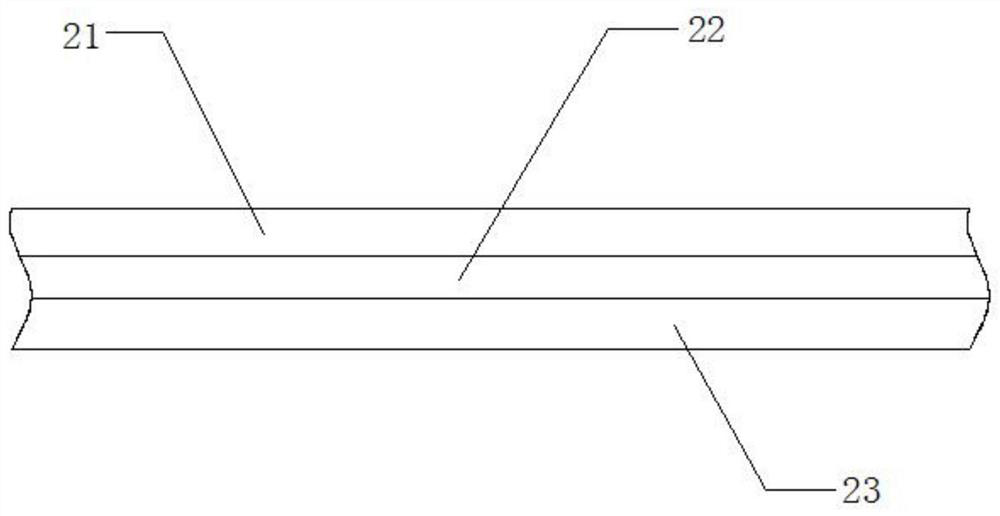

[0058] The main material of the insulation board 2 includes a pressure-resistant insulation layer 21, a flexible layer 22 and a flame-retardant layer 23;

[0059] The compressive insulation layer 21 comprises 40 parts by weight of sepiolite powder, 20 parts by weight of foamed magnesium cement and 10 parts by weight of EPS particles;

[0060] The flexible layer 22 includes 20 parts by weight of sodium silicate, 30 parts by weight of volcanic rock fiber and 10 parts by weight of polystyrene;

[0061] The flame retardant layer 23 includes 2 parts by weight of phenolic resin, 2 parts by weight of rock wool and 3 parts by weight of nano-bentonite;

[0062] The auxiliary ma...

Embodiment 2

[0079] As a preferred solution of Embodiment 1, it includes the main material of the insulation board 2, the auxiliary material of the insulation board 2, the main material of the decorative board 1 and the auxiliary material of the decorative board 1;

[0080] The main material of the insulation board 2 includes a pressure-resistant insulation layer 21, a flexible layer 22 and a flame-retardant layer 23;

[0081] The compressive insulation layer 21 includes 80 parts by weight of sepiolite powder, 60 parts by weight of foamed magnesium cement and 30 parts by weight of EPS particles;

[0082] The flexible layer 22 includes 40 parts by weight of sodium silicate, 50 parts by weight of volcanic rock fiber and 20 parts by weight of polystyrene;

[0083] The flame retardant layer 23 includes 8 parts by weight of phenolic resin, 10 parts by weight of rock wool and 7 parts by weight of nano-bentonite;

[0084] The auxiliary materials of the insulation board 2 include 7 parts by weigh...

Embodiment 3

[0089] As another preferred solution of the first embodiment, it includes the main material of the insulation board 2, the auxiliary material of the insulation board 2, the main material of the decorative board 1 and the auxiliary material of the decorative board 1;

[0090] The main material of the insulation board 2 includes a pressure-resistant insulation layer 21, a flexible layer 22 and a flame-retardant layer 23;

[0091] The compressive insulation layer 21 includes 60 parts by weight of sepiolite powder, 40 parts by weight of foamed magnesium cement and 20 parts by weight of EPS particles;

[0092] The flexible layer 22 includes 30 parts by weight of sodium silicate, 40 parts by weight of volcanic rock fiber and 15 parts by weight of polystyrene;

[0093] The flame retardant layer 23 includes 5 parts by weight of phenolic resin, 6 parts by weight of rock wool and 5 parts by weight of nano-bentonite;

[0094] The auxiliary materials of the insulation board 2 include 5 p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com