Flow adjustable vibratory feeding device and operation method thereof

A technology of vibrating feeding and operating methods, which is applied to vibrating conveyors, loading/unloading, transportation and packaging, etc., can solve the problems that vibrating feeders cannot feed and measure materials, and achieve simple structure, improved efficiency, and reduced safety hidden effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

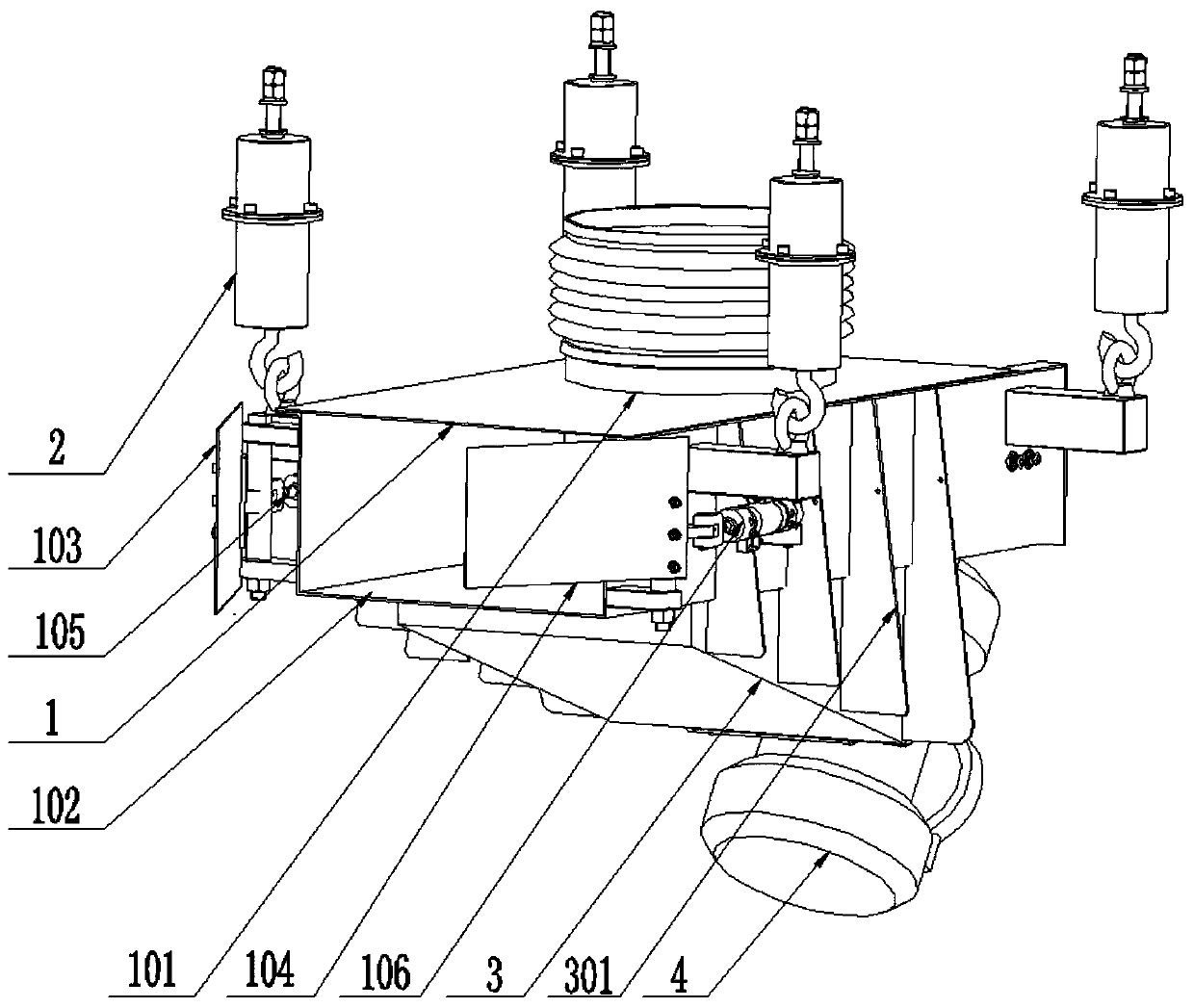

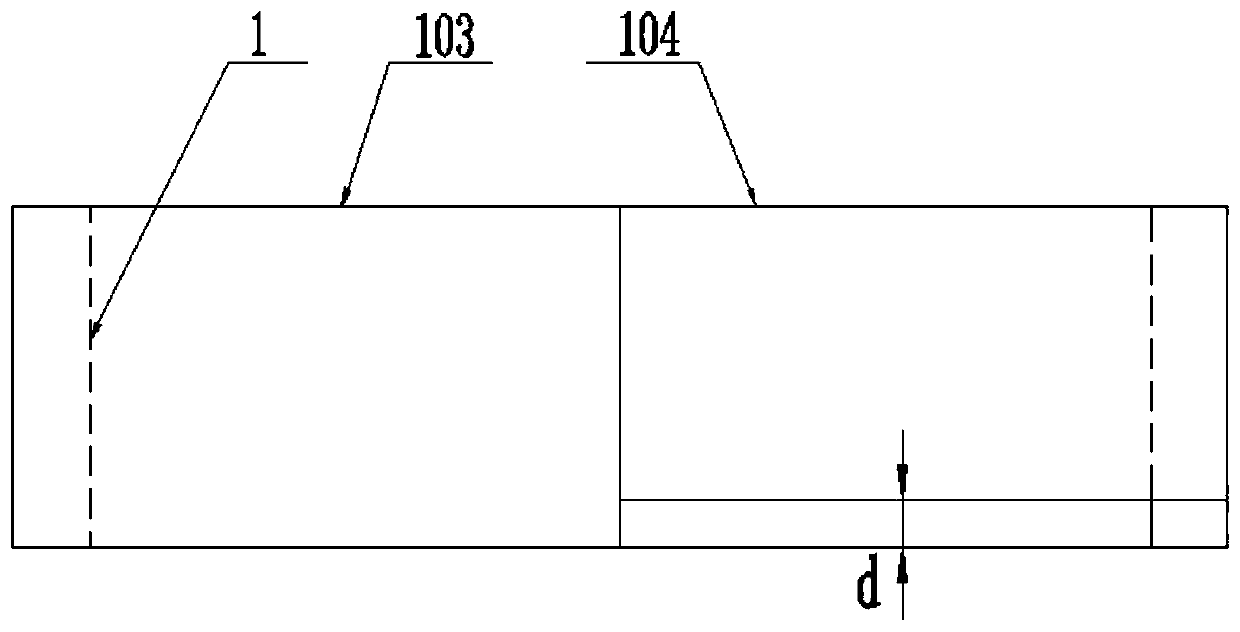

[0035] like figure 1 and figure 2 As shown, the vibration feeding device with adjustable flow rate of the present invention includes a hopper 1, a shock absorbing mechanism 2 above the hopper 1, a mounting seat 3 below the hopper 1, and a vibration motor 4 on the mounting seat 3. It is provided with a material inlet 101 and a material outlet 102, and also includes a hopper door mechanism that can open or partially close the material outlet 102. The hopper door mechanism includes a first hopper door 103 and a second hopper door 104. The first The hopper door 103 and the second hopper door 104 can be rotated to open or partially close the discharge port 102. There is a certain distance between the bottom of the second hopper door 104 and the lower end surface of the discharge port 102; The first cylinder 105 for opening and closing the hopper door 103 and the second cylinder 106 for driving the opening and closing of the second hopper door 104, the fixed end of the first cylin...

Embodiment 2

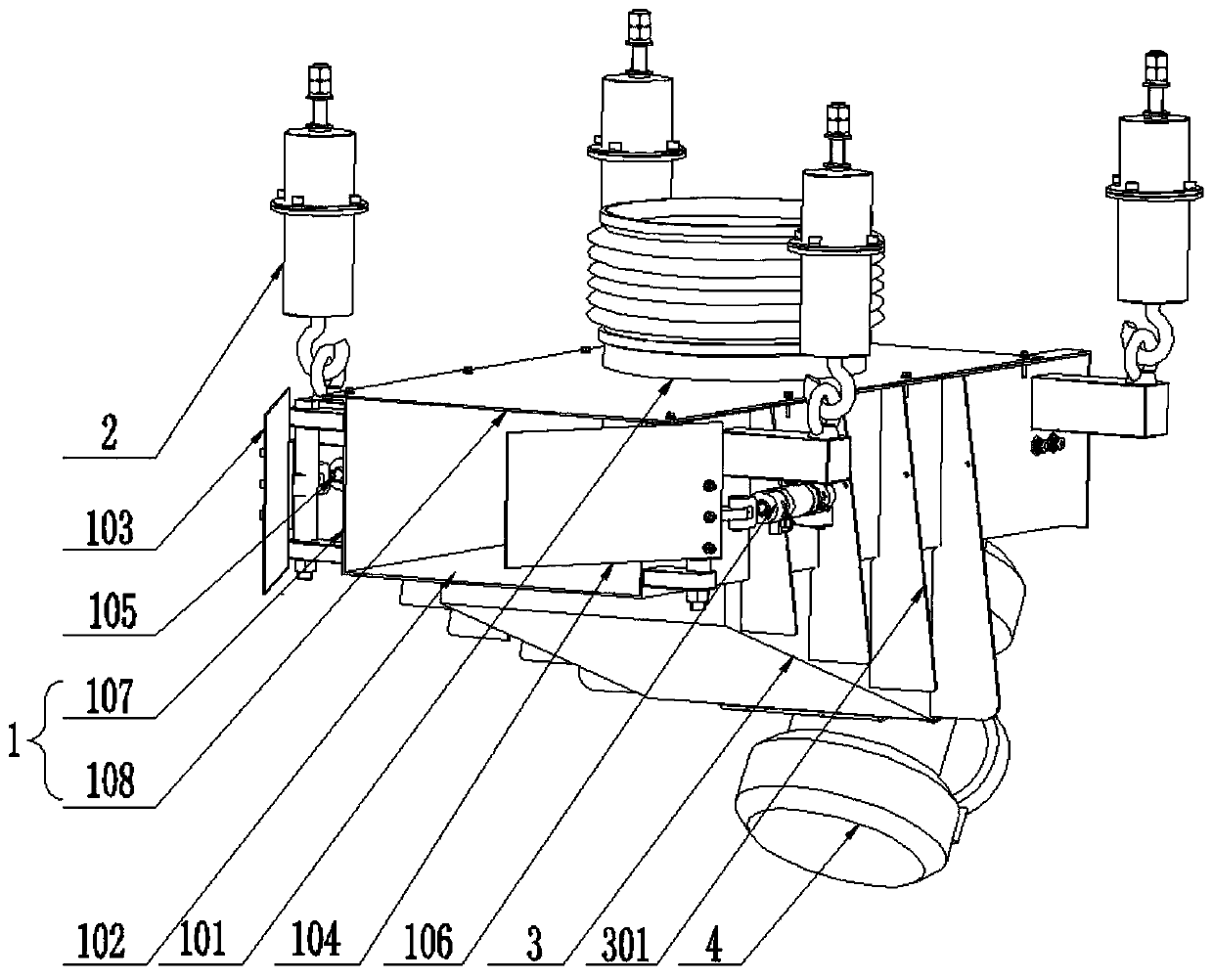

[0037] This embodiment is a further improvement made on the basis of Embodiment 1, as image 3 As shown, the hopper 1 of the present invention is detachable. The hopper 1 includes a hopper 107 and a material cover 108 arranged above the hopper 107. The hopper 107 and the material cover 108 are connected by bolts. It is convenient to clean and maintain the hopper, and it is also convenient to store and transport the hopper.

Embodiment 3

[0039] This embodiment is a further improvement made on the basis of Embodiment 1, as Figure 4 ~ Figure 7As shown, the feed inlet 101 of the present invention is provided with a feed pipe, the feed pipe extends into the hopper 1, and the distance between the bottom of the feed pipe and the bottom of the hopper 1 is continuously adjustable; the feed pipe Including the first feed pipe 501 arranged in the feed port 101 and matched with the feed port 101 and the second feed pipe 503 arranged in the first feed pipe 502, the first feed pipe 501 and the second feed pipe 501 The tubes 503 can slide mutually, the first feeding tube 501 is provided with a first chute 502, the second feeding tube 503 is provided with a second chute 504 at a corresponding position, the first feeding tube 501 and the second feeding tube 503 connected by bolts. The thickness of the material in the hopper can be controlled according to the specifications of different materials and the required feeding mete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com