Method for producing unidirectional moisture absorption and guiding fabric

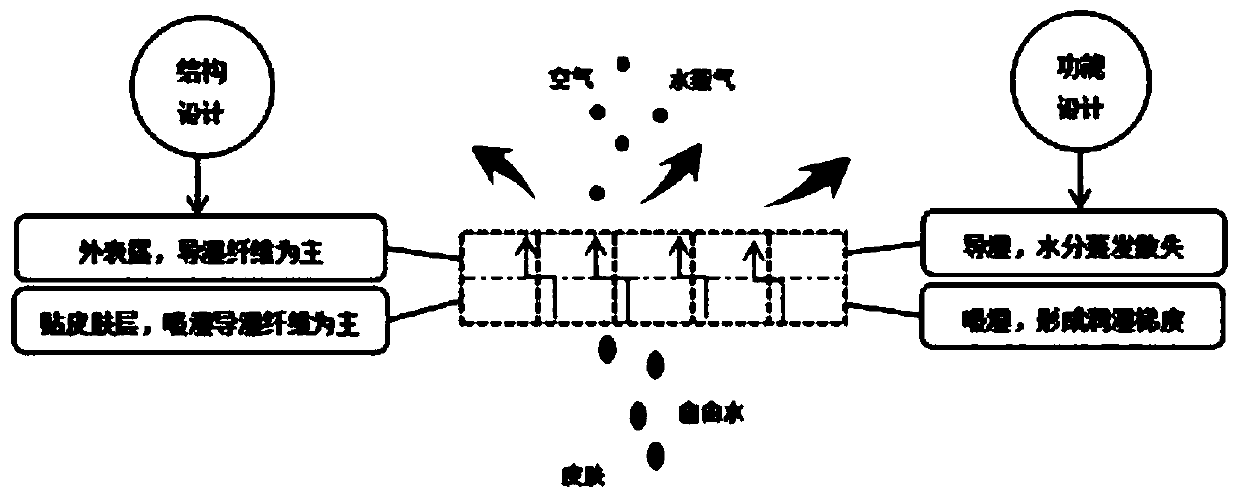

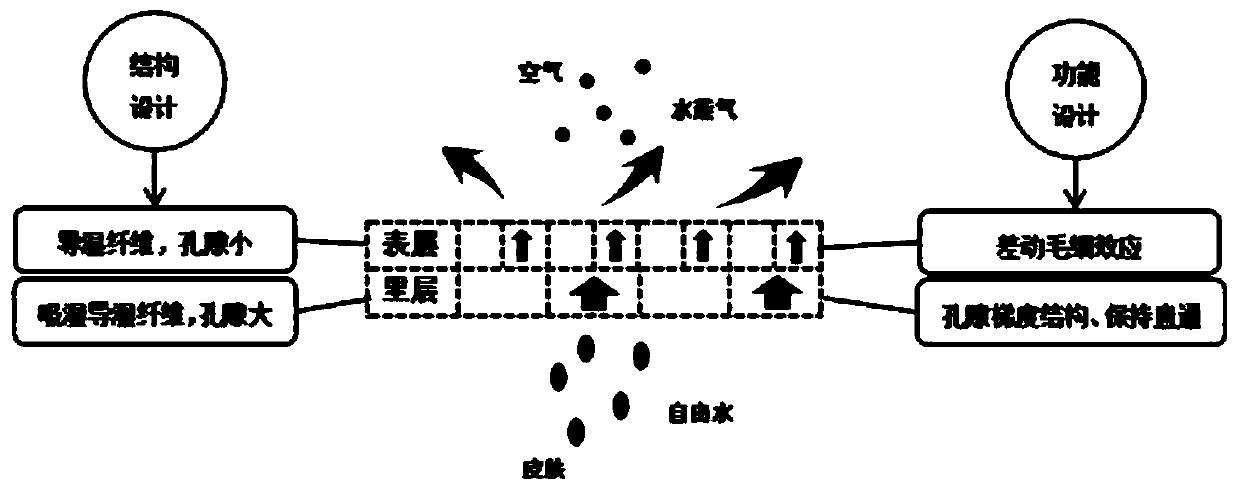

A technology of one-way moisture absorption and production method, applied in textile, fabric, multi-strand fabric and other directions, can solve the problems of poor wearing comfort and insufficient moisture conductivity of chemical fiber fabrics, and achieve the effect of wide application range and high practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The preparation of a comfortable unidirectional moisture-absorbing and moisture-conductive fabric with a single-layer structure includes the following steps:

[0037] Step 1. Select the required raw materials, coolmax fiber with an average length of 38mm and a linear density of 1.63dtex; hemp fiber with an average length of 38mm and a linear density of 1.56dtex; cotton with an average length of 38mm and a linear density of 1.33dtex fiber.

[0038] Step 2. Purely spun the coolmax fiber in step 1 into a moisture-transmitting functional yarn, and blend the hemp and cotton fiber in step 1 with a blending ratio of 70:30 to make a moisture-absorbing functional yarn. The twist of the yarn The design is 800 twists / m, and the yarn linear density is 14.58tex.

[0039] When spinning, yarn goes through the processes of opening and cleaning, carding, combing, drawing (1 to 3 passes), roving, spun yarn, and winding.

[0040] Step 3, perform performance test on the yarn prepared in step 2, m...

Embodiment 2

[0114] The preparation of coolmax fiber, hemp fiber and cotton fiber with different single-layer structure and comfortable unidirectional moisture-absorbing and moisture-transmitting fabric includes the following steps:

[0115] Step 1. Select the required raw materials, coolmax fiber with an average length of 38mm and a linear density of 1.63dtex; hemp fiber with an average length of 38mm and a linear density of 1.56dtex; cotton with an average length of 38mm and a linear density of 1.33dtex fiber.

[0116] Step 2, pure yarn spinning, using coolmax fiber in step 1 to spin into moisture-transmitting functional yarn, yarn blending, using hemp fiber and cotton fiber in step 1 with blending ratio of 70 / 30 and 50 / 50 respectively Spinning into moisture-absorbing functional yarn; among them, the yarn twist is designed to be 800 twists / m, and the yarn linear density is designed to be 14.58tex.

[0117] When spinning, yarn goes through the processes of opening and cleaning, carding, combing...

Embodiment 3

[0161] The preparation of a comfortable unidirectional moisture-absorbing and moisture-conductive fabric with a single-layer structure with different fabric warp and weft tightness specifically includes the following steps:

[0162] Steps 1 to 3 are the same as in Example 1.

[0163] Step 4, select the required yarn, the warp yarn is a coolmax pure spun yarn with a linear density of 14.58 tex, and the weft yarn is a blended yarn of hemp and cotton fiber with a linear density of 14.58 tex in a blending ratio of 70 / 30.

[0164] Step 5: Use the coolmax pure spun yarn and hemp / cotton blended yarn selected in step 4 to make a single-layer fabric through a loom.

[0165] Among them, the warp yarn is 14.58tex coolmax pure spinning yarn, and the weft yarn is 14.58tex hemp / cotton blended yarn with a blending ratio of 70 / 30; image 3 As shown, the fabric weave uses five three-fly warp satin weaves; the warp tightness of the fabric is 50%, the weft tightness is 45%, the warp density is 354 thread...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com