Oil damper and design method thereof

A technology of hydraulic shock absorbers and pressure cylinders, applied in shock absorbers, liquid shock absorbers, shock absorbers, etc., can solve problems such as structural stability and reliability need to be improved, poor operating conditions, etc. Effective and reliable structural design, easy to debug, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

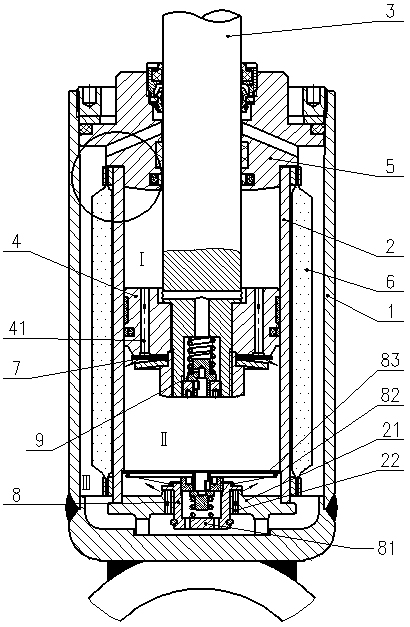

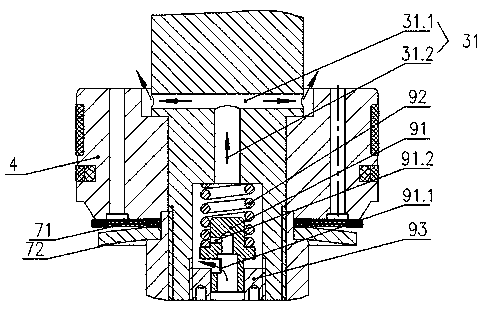

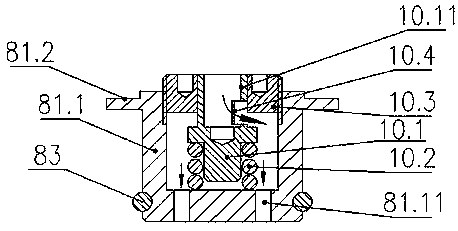

[0033] Combine below Figure 1 to Figure 4 Embodiments of the present invention are described in detail.

[0034] The hydraulic shock absorber includes an oil storage cylinder 1, a pressure cylinder 2 arranged in the oil storage cylinder 1, a piston rod 3 extending into the pressure cylinder 2 at one end, a piston 4 located in the pressure cylinder 2 and connected to the piston rod 3, The guide seat 5, which seals with the top of the oil storage cylinder 1 and guides and supports the movement of the piston rod 3, extends into the pressure cylinder 2 and abuts against the top surface of the pressure cylinder 2. The piston 4 divides the pressure cylinder 2 into two parts. The piston upper chamber I above the piston 4 and the piston lower chamber II below the piston 4 form an oil storage chamber III between the storage cylinder oil 1 and the pressure cylinder 2. The oil storage chamber III has a sealed air bag 6, and the piston The rod 3 is equipped with a stretch throttle elast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com