Light-weight high-strength automobile tail door electric driving reducer

An electric drive reducer, high-strength technology, applied in door/window accessories, portable lifting devices, gear transmissions, etc., can solve the problems that it is difficult to meet the requirements of lightweight tailgate reducers, cumbersome processing and assembly, and high comprehensive cost , to achieve convenient and fast processing, improve production and processing efficiency, and low overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

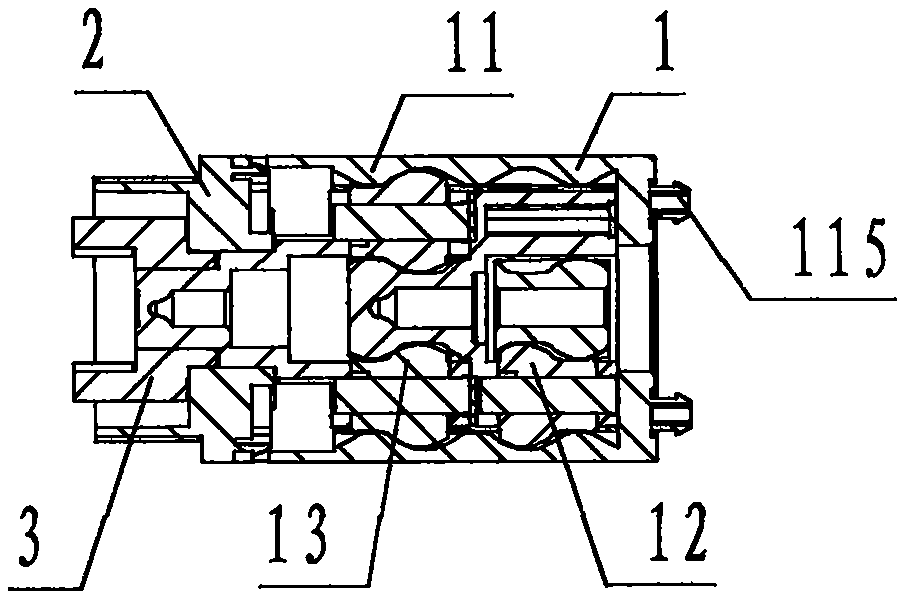

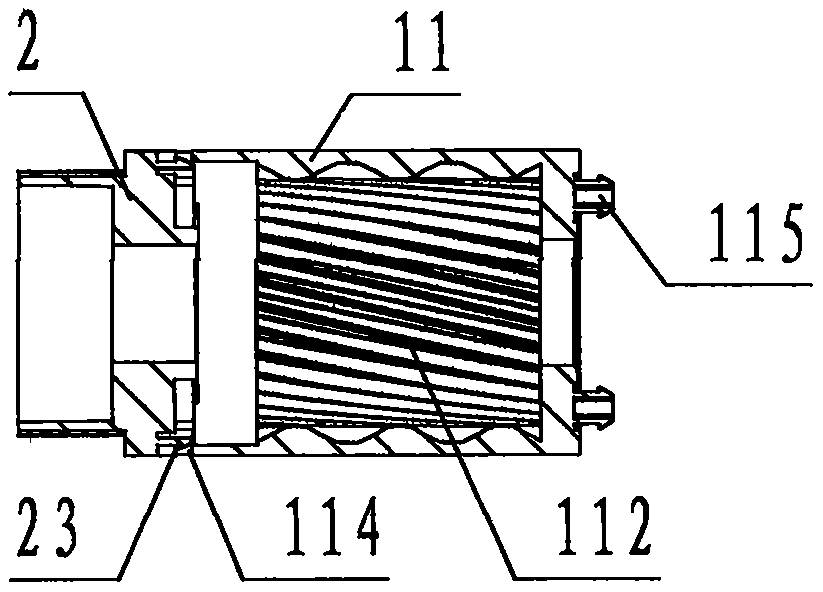

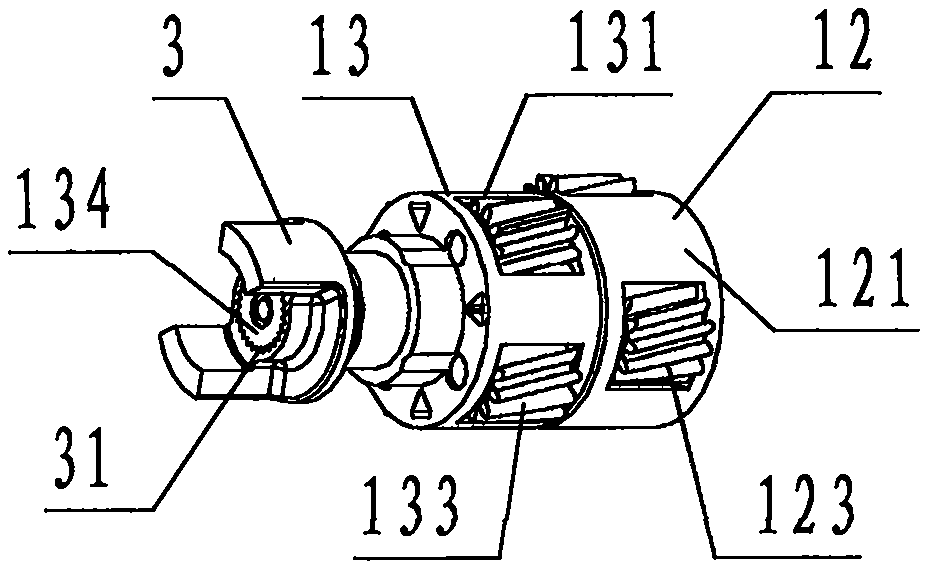

[0031] refer to Figure 1 to Figure 8 , a light-weight and high-strength automotive tailgate electric drive reducer of the present invention includes a two-stage planetary reducer 1, a connecting head 2 and a shaft coupling 3, wherein: the two-stage planetary reducer 1 consists of a reducer housing 11. A wheel core 12 and B wheel core 13 are formed. The reducer housing 11 is a cylindrical tubular plastic member. The inner wall of the reducer housing 11 is provided with cylindrical inner circular helical teeth called inner helical teeth 112 The left edge of the reducer housing 11 is evenly provided with four rectangular notches called tenon grooves 113, and the upper and lower parts of the left pipe wall of the reducer housing 11 are respectively provided with two rectangular through holes called bayonets 114; The right side of the reducer housing 11 is protruded with a four-lobed cone-shaped cone buckle 115 for connecting to the motor;

[0032] The A wheel core 12 is composed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com