Gas stove control method and gas stove

A control method and technology of gas stoves, applied in the field of gas stoves, can solve the problems of low reliability, inability to sense, and failure of anti-dry burning function, and achieve the effect of high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

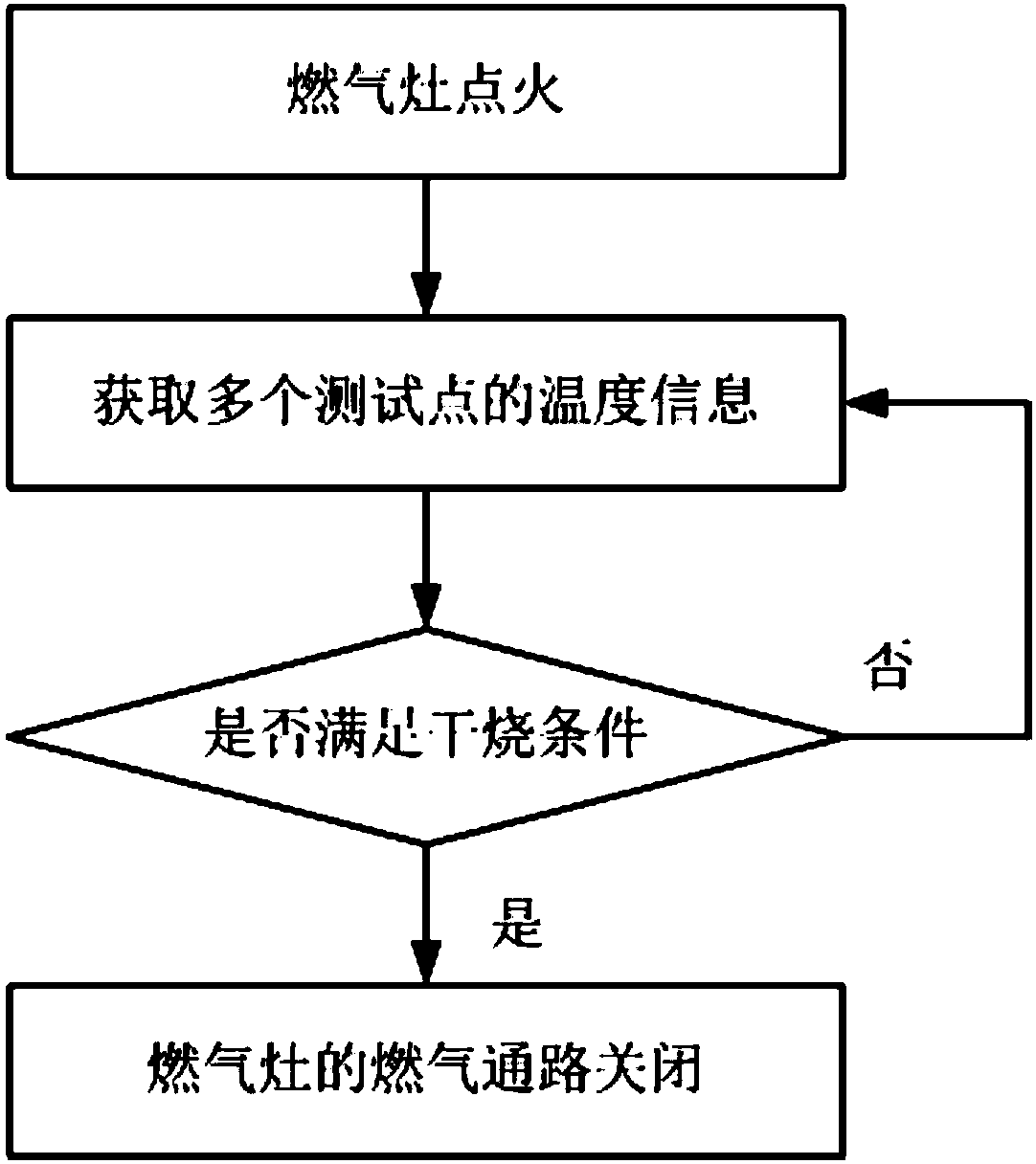

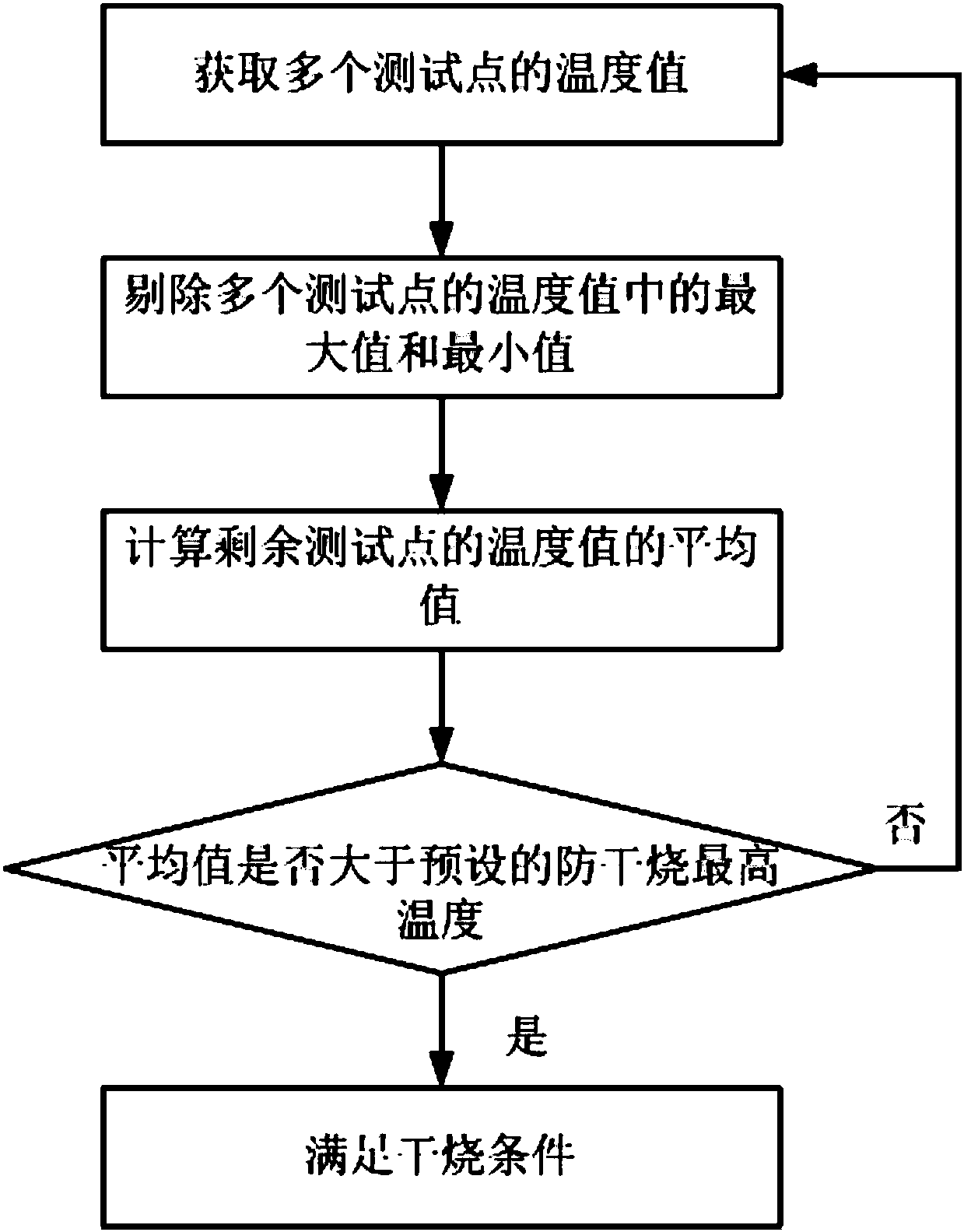

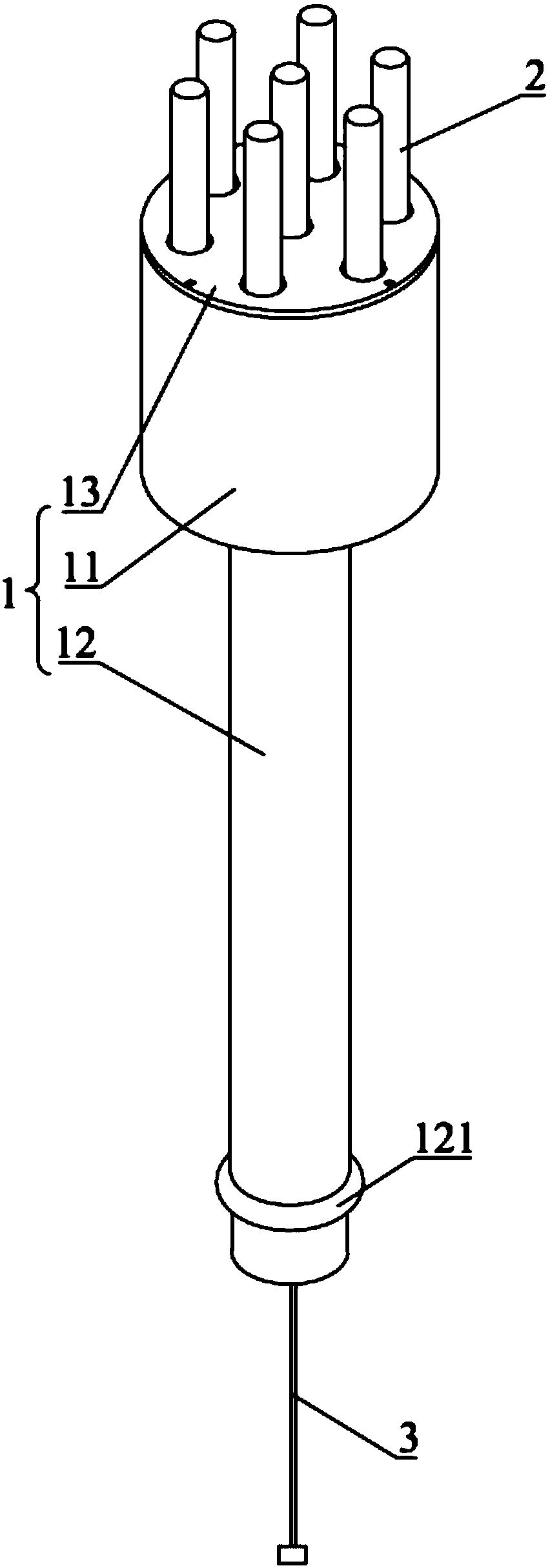

[0032] Such as figure 1 As shown, this embodiment provides a gas stove control method, which can realize the function of preventing dry burning of the gas stove. Specifically, after the gas stove is ignited, multiple test points are selected on the bottom of the pot, and the temperature information of the test points is obtained, and the temperature information of the multiple test points is comprehensively analyzed to determine whether the dry-burning condition is met. When the dry-burning condition is met, The gas channel of the gas stove is closed, and the gas supply is stopped, so as to realize the anti-dry function, improve the safety performance of the gas stove, and ensure the personal safety of the user. When the gas stove does not meet the dry burning condition, it indicates that the gas stove is in a normal working state, the gas passage of the gas stove remains open, and the temperature information of the test point is continuously obtained for re-judgment. The con...

Embodiment 2

[0052] This embodiment provides a control method of a gas stove and a gas stove, the structure of the gas stove is the same as that in Embodiment 1, the control method of the gas stove is roughly the same as that in Embodiment 1, and is different from that in Embodiment 1 The most important thing is the obtained temperature information and dry burning conditions.

[0053] Specifically, such as Figure 8 As shown, the temperature information of multiple test points in this embodiment includes the temperature rise rate of the test points. When judging whether the appliance on the gas stove is dry-burned, by calculating the average value of the temperature rise rate of multiple test points, it is judged whether the average value of the temperature rise rate is greater than the preset maximum temperature rise rate for preventing dry burning. If the average value is greater than the maximum temperature rise rate of anti-dry burning, it indicates that the appliance is in a state of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com