An annular pipe sealing ring for ultra-low temperature dynamic sealing and its processing method

A technology of dynamic sealing and processing method, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of inability to apply dynamic sealing, bursting, tearing, sealing ring failure, etc., to reduce processing costs and improve accuracy. and strength, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

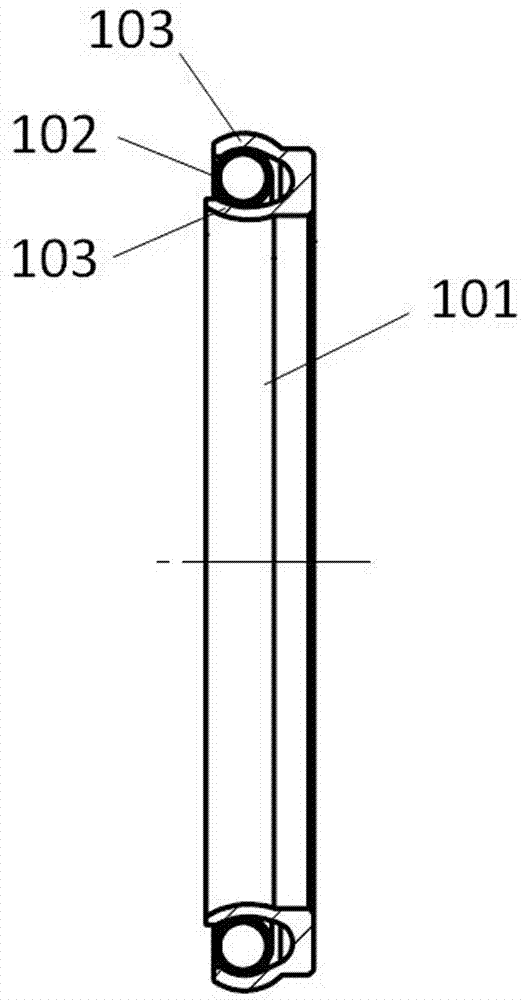

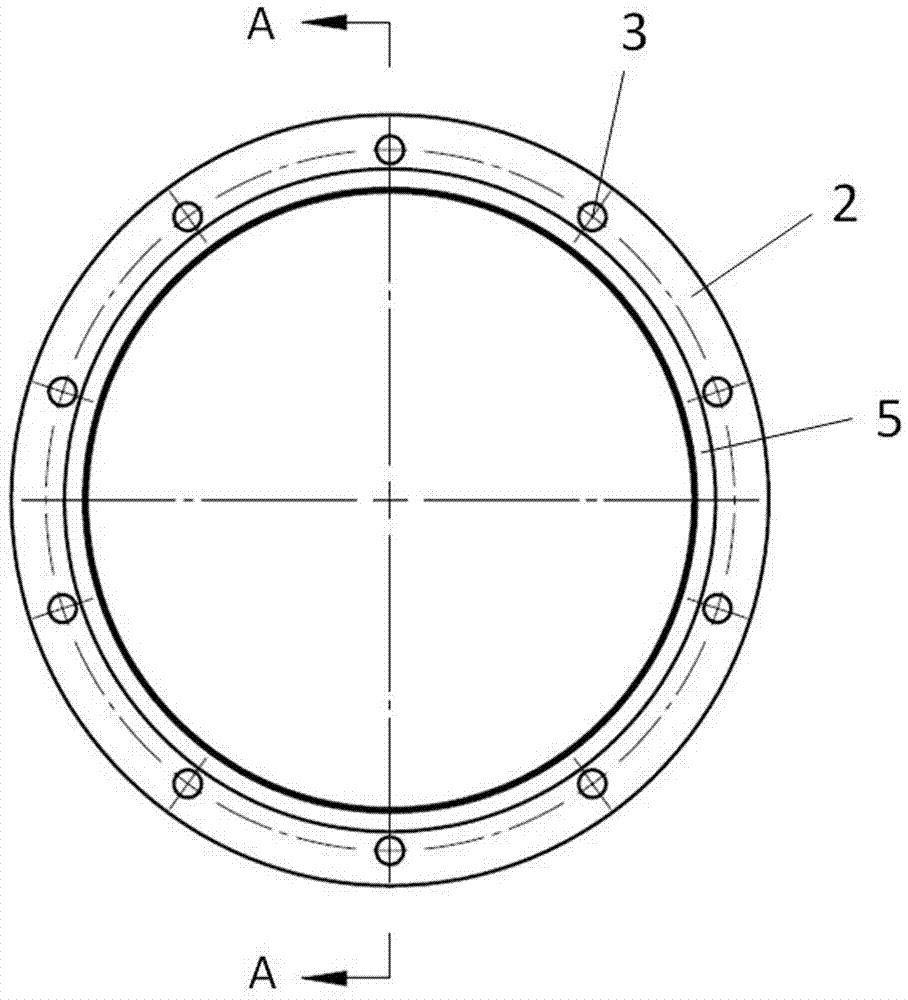

[0032] A first embodiment of an annular pipe sealing ring for ultra-low temperature dynamic sealing of the present invention, such as Figure 2 to Figure 4As shown, it includes a tube 2 provided with a hollow cavity 1, and a group of air inlet holes 3 arranged on the tube 2, the tube 2 is annular, and a support 4 is provided in the cavity 1; the support 4 is an annular rod made of low temperature resistant material, the material diameter of the annular rod is smaller than the inner diameter of the pipe 2; the pipe 2 is provided with a ring-shaped support 5, and the support 5 is connected to the mounting surface for externally installing the annular pipe sealing ring , the support 5 is set on the inner ring surface of the tube 2; a group of air inlets 3 is not less than 2 in number and distributed in an annular array, which are set on the side end or the outer ring surface of the tube 2 according to the direction of the high-pressure fluid ; The tube 2 is made of PTFE or PCTFE ...

Embodiment 2

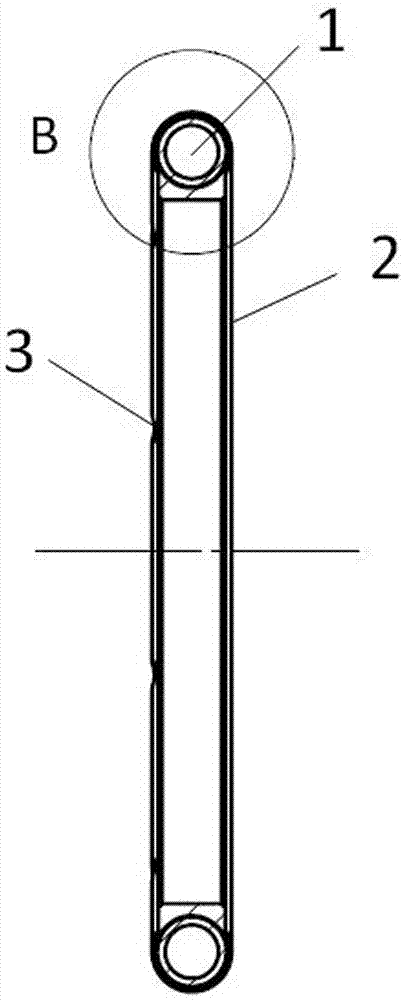

[0045] A second embodiment of the annular pipe sealing ring used for ultra-low temperature dynamic sealing of the present invention, such as Figure 5 and Figure 6 As shown, it includes a tube 2 provided with a hollow cavity 1, and a group of air inlet holes 3 arranged on the tube 2, the tube 2 is annular, and a support 4 is provided in the cavity 1; the support 4 is an annular support tube made of low temperature resistant material, the material diameter of the annular support tube is smaller than the inner diameter of the tube 2, the tube 2 is a round tube, and the material diameter (the outer diameter of the cross section of the round tube) is 60 mm, the ring tube The outer diameter of the sealing ring is 2m, and the one-sided gap between the annular support pipe and the pipe 2 is 5.5mm; The mounting surfaces are connected, and the support 5 is arranged at the side end of the pipe 2; the number of the group of air inlets 3 is not less than 2, and they are distributed in a...

Embodiment 3

[0048] A third embodiment of an annular pipe sealing ring for ultra-low temperature dynamic sealing of the present invention, such as Figure 7 and Figure 8 As shown, it includes a tube 2 with a hollow cavity 1, and a group of air inlet holes 3 arranged on the tube 2. The tube 2 is annular, and a support 4 is provided in the cavity 1. The support 4 is a ring-shaped spring ring formed by spirally winding metal sheets; the tube 2 is a round tube, and the material diameter (the outer diameter of the cross-section of the round tube) is 4mm, the outer diameter of the annular tube sealing ring is 6mm, and the spring ring The one-sided gap between the pipe 2 and the pipe 2 is 0.05mm; the pipe 2 is provided with a ring-shaped support 5, and the support 5 is connected with the mounting surface for externally installing the annular pipe sealing ring, and the support 5 is arranged on the pipe 2 The outer ring surface of the outer ring surface; the number of the group of air intake hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com