A kind of preparation method of co-ldh zinc-air battery catalyst of sheet structure

A zinc-air battery and sheet-like structure technology, applied in the field of zinc-air battery catalysts, can solve the problems of large specific surface area of transition metal hydroxide, restricting the application of transition metal hydroxide, exposure of active sites, etc., so as to improve electrocatalysis The effect of activity, mild reaction conditions and high reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

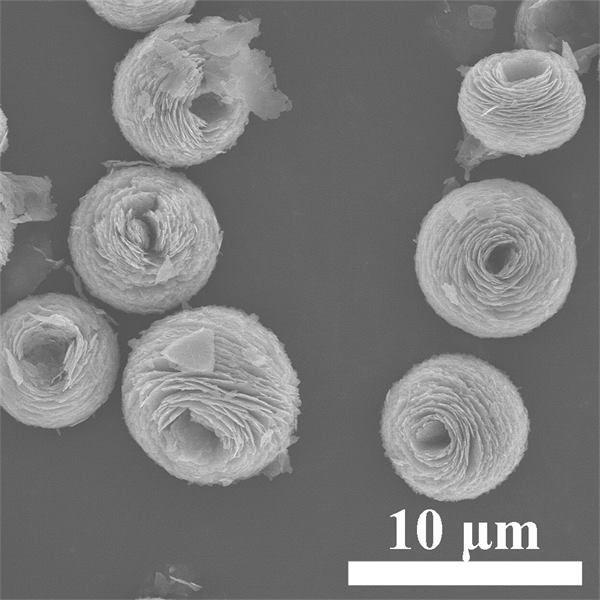

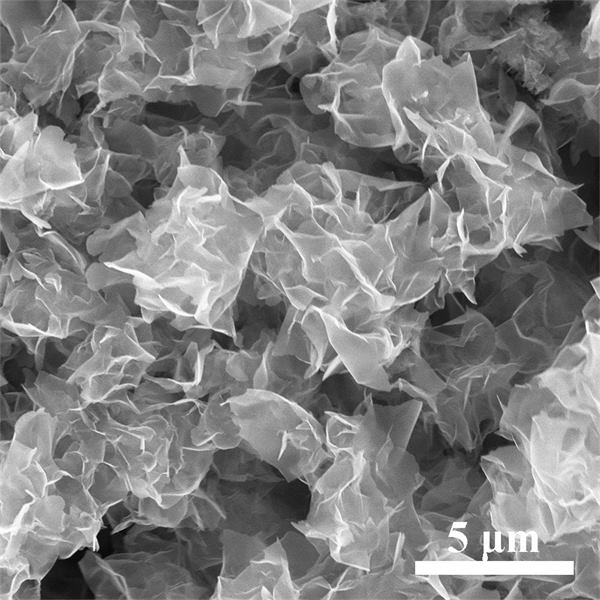

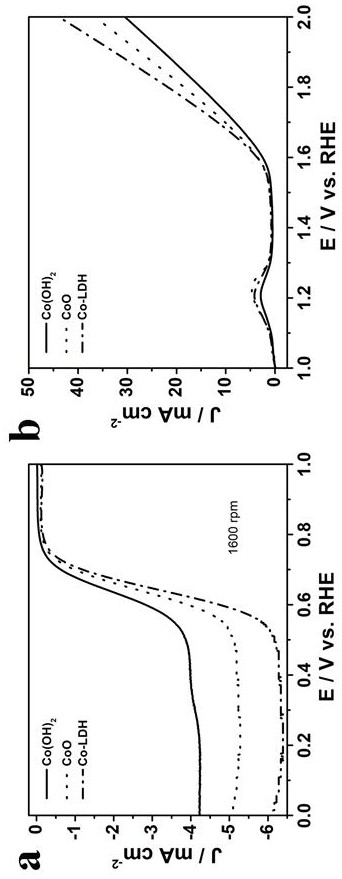

[0023] Dissolve 0.249g of cobalt acetate and 0.125g of hydrazine in 30mL of distilled water, stir at 25°C for 10min, and finally transfer to a polytetrafluoroethylene-lined stainless steel autoclave at 120°C for 6h, and wait for the reaction kettle to cool down to room temperature naturally , after being washed several times with water twice, put it in an oven and dry for 12h to obtain the pink intermediate product Co(OH) 2 ; 40mg of the above-mentioned pink intermediate product Co(OH) 2 Ultrasonic dispersion in 60mL methanol solution, after the dispersion is uniform, add 0.985g dimethylimidazole, stir for 30min, transfer to a polytetrafluoroethylene-lined reactor and keep at 100°C for 16h, wash with methanol for several times, and then dried in a vacuum oven to obtain lavender Co-LDH zinc-air battery catalyst. Depend on figure 1 It can be seen that the Co-LDH electrocatalyst prepared in this example is a two-dimensional nanosheet structure with a thickness between 5-10 nm. ...

Embodiment 2

[0026] Dissolve 0.249g of cobalt acetate and 0.063g of hydrazine in 30mL of distilled water, stir at 25°C for 10min, and finally transfer to a polytetrafluoroethylene-lined stainless steel autoclave at 120°C for 6h, and wait for the reaction kettle to cool naturally to room temperature , after being washed several times with water twice, put it in an oven and dry for 12h to obtain the pink intermediate product Co(OH) 2 , 40mg of the above pink intermediate product Co(OH) 2 Ultrasonic dispersion in 60mL methanol solution, after the dispersion is uniform, add 0.985g dimethylimidazole, stir for 30min, transfer to a polytetrafluoroethylene-lined reactor and keep at 100°C for 16h, wash with methanol for several times, and then dried in a vacuum oven to obtain lavender Co-LDH zinc-air battery catalyst.

Embodiment 3

[0028] Dissolve 0.249g of cobalt acetate and 0.125g of hydrazine in 30mL of distilled water, stir at 25°C for 10min, and finally transfer to a polytetrafluoroethylene-lined stainless steel autoclave at 120°C for 6h, and wait for the reaction kettle to cool down to room temperature naturally , after being washed several times with water twice, put it in an oven and dry for 12h to obtain the pink intermediate product Co(OH) 2 , 40mg of the above pink intermediate product Co(OH) 2 Ultrasonic dispersion in 60mL methanol solution, after the dispersion is uniform, add 0.493g dimethylimidazole, stir for 30min, then transfer to a polytetrafluoroethylene hydrothermal kettle and keep at 100°C for 16h, wash with methanol several times after the reaction is completed, Then dried in a vacuum oven to obtain lavender Co-LDH zinc-air battery catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com