Wear-resistant copper zinc alloy and mechanical device using same

A wear-resistant, copper-zinc technology, applied in the direction of mechanical equipment, anti-centrifugal force rotating parts, shafts and bearings, can solve the problem of increasing the aggressiveness of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

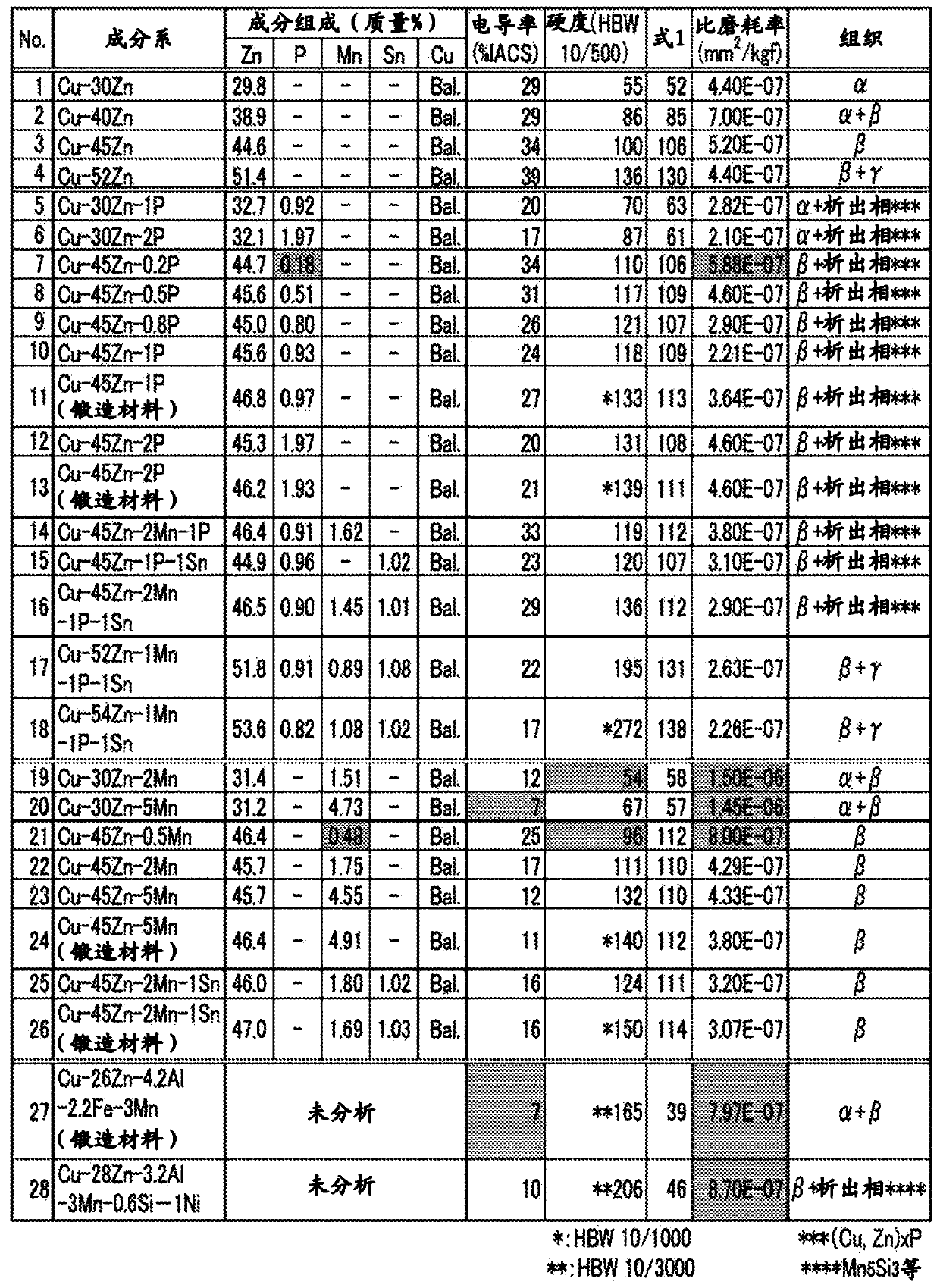

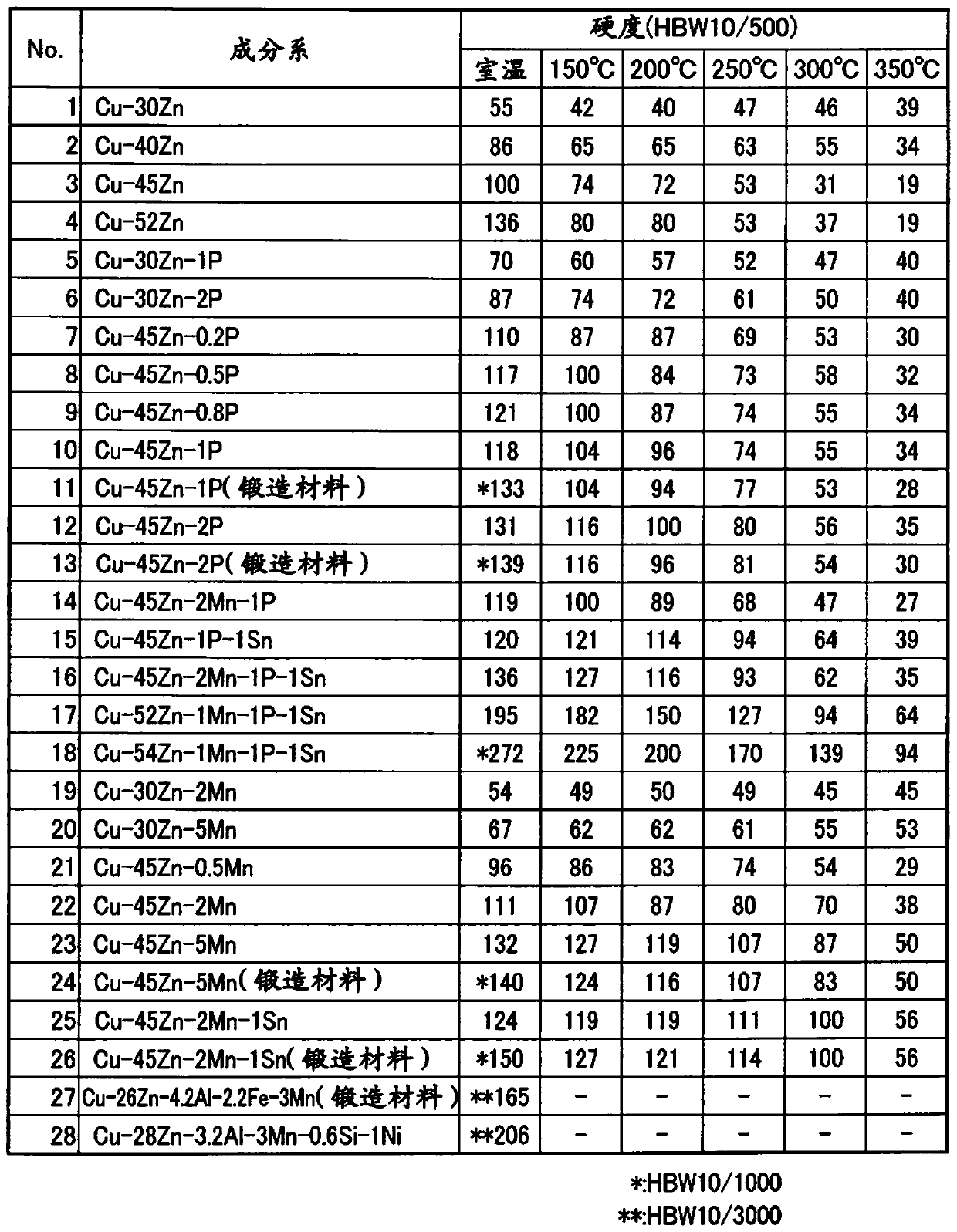

[0068] Hereinafter, for an embodiment of one of the wear-resistant copper-zinc alloys according to the present disclosure, refer to figure 1 Be explained.

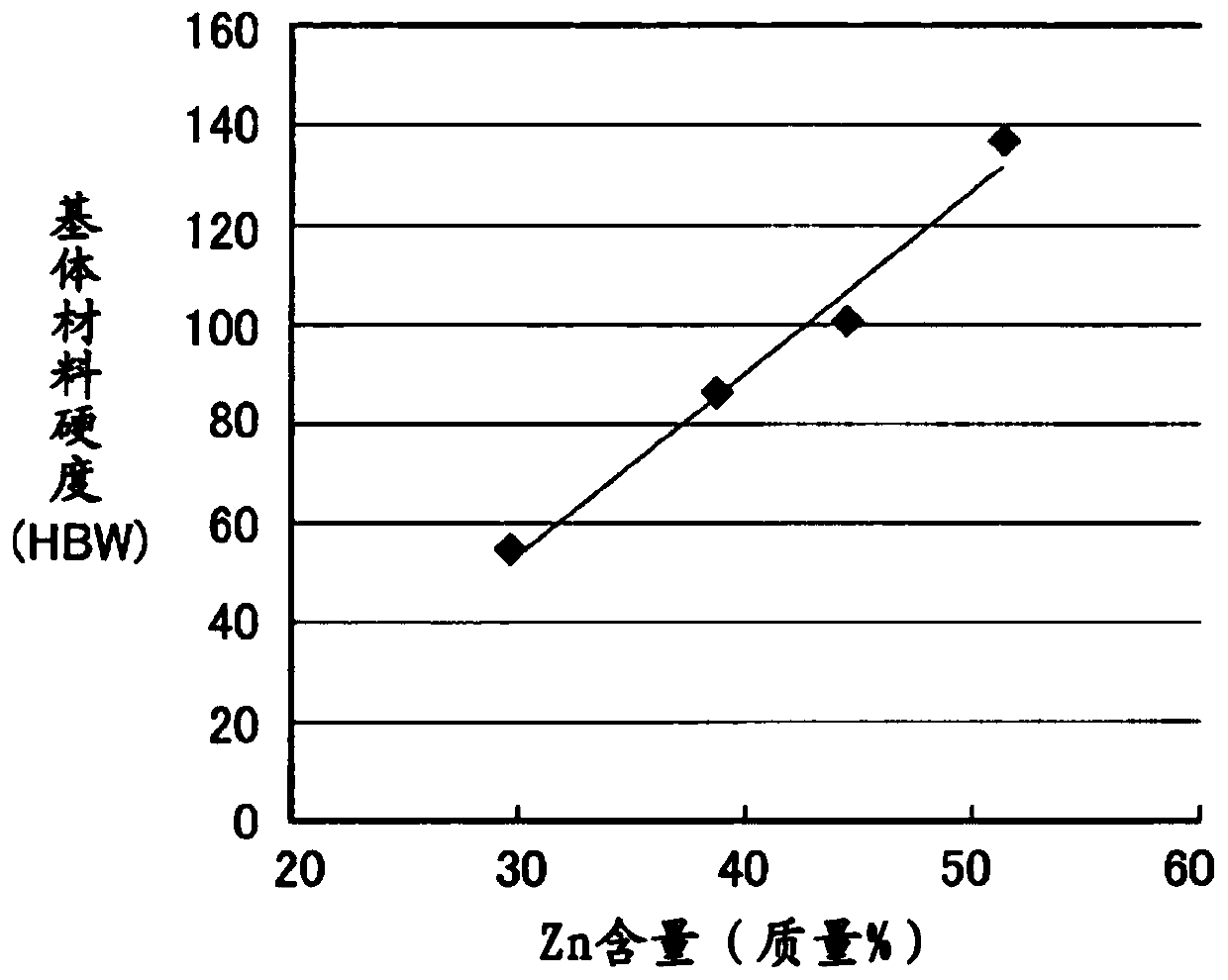

[0069] Such as figure 1 No.5, 6, 8-18, 22-26, in this embodiment, the wear-resistant copper-zinc alloy is a copper-zinc alloy containing 28-55% by mass of Zn (base material: refer to No. .1 to 4), a material containing at least one of P and Mn which is solid-dissolved in the matrix phase. Since Zn is cheaper than Cu, its content is increased, and its content makes the parent phase α phase, (α+β) phase, β phase or (β+γ) phase. For example, the Zn content is 28 to 55% by mass, typically 30, 40, 45 or 52% by mass.

[0070] As a method of improving wear resistance, a method of dispersing hard oxides and hard intermetallic compounds represented by alumina having a Vickers hardness of about 1500 HV or higher in the matrix phase is also used, However, in this embodiment, the hardness is increased by solid-solution of P and Mn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com