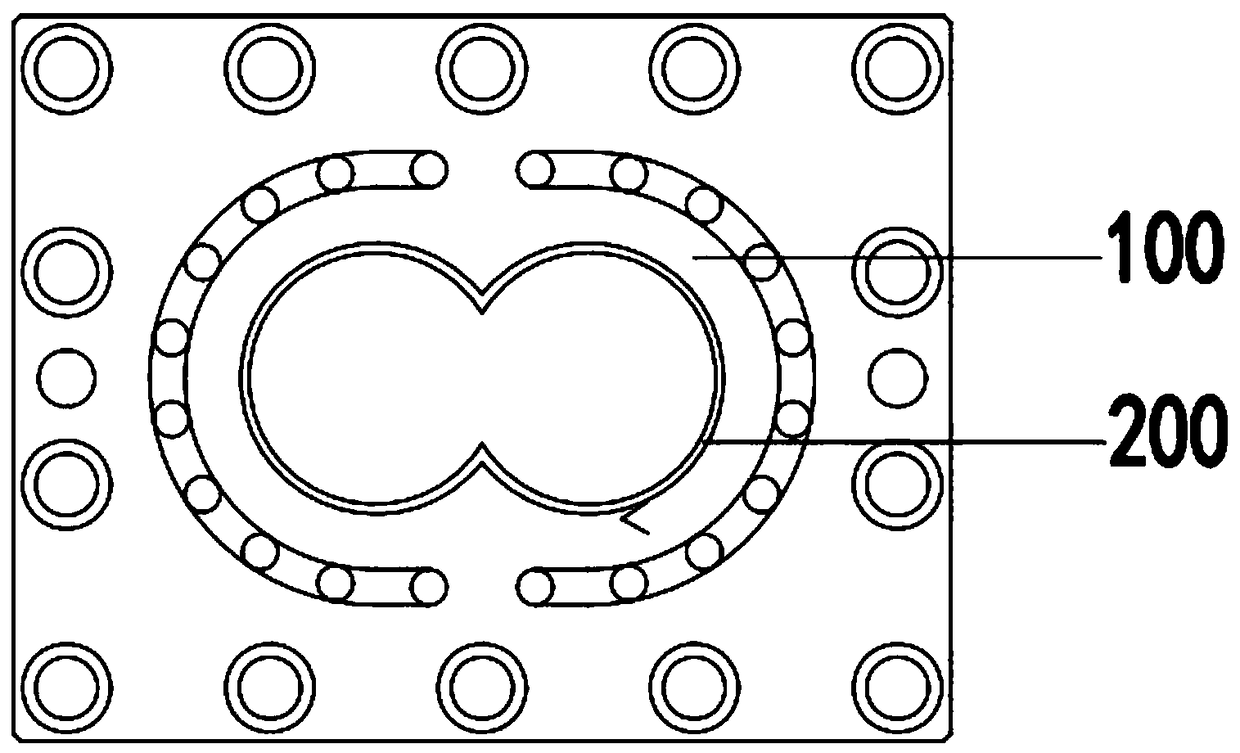

Cylinder with double metal extruders and preparation method of cylinder

A technology of bimetal and machine barrel, which is applied in the field of plastic processing, can solve the problems of unstable product quality and short service life of the barrel, and achieve the effects of sensitive response to the temperature of the barrel, saving processing costs, and high processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The invention provides a method for preparing a bimetal extruder barrel, which specifically includes the following steps:

[0033] (1) Provide a cylinder base; in order to form the alloy according to the shape of the cylinder base, it is necessary to add a set of inner molds concentric with the cylinder base in the cylinder, and seal the bottom end, the inner mold and the cylinder base The gap between them should be calculated and determined according to the designed coating thickness; and in order to prevent the moisture and impurities on the surface of the substrate from affecting the combination of the alloy and the substrate, the surface of the substrate and the inner mold must first be thoroughly cleaned and dried;

[0034] (2) In order to prevent the alloy from sticking to the inner mold after sintering, brush a layer of high-temperature release agent on the surface of the dried inner mold, and assemble it with the cylinder base after the inner mold is fully dried;...

Embodiment 1

[0048] The preparation of embodiment 1 bimetal extruder barrel

[0049] Nickel-based alloy powder is selected, and its chemical composition is B: 2.5%, C: 0.7%, Cr: 15%, Si: 3.8%, Fe: 14%, W: 0.5%, Ni: 63.5%; the powder specification is 140 / 325 mesh, hardness HRC55. Type 75 is selected as the base body of the cylinder, the diameter of the inner hole is the size of the finished product plus 3.6mm, and the surface roughness is Ra1.6um. The inner mold is designed and processed according to the size of the inner hole. Specifically include the following steps:

[0050] (1) Substrate cleaning: Provide a cylinder substrate and inner mold, and thoroughly clean the surface of the cylinder substrate and inner mold;

[0051] (2) Mold assembly: Brush a layer of high-temperature-resistant paint on the surface of the inner mold, and assemble it with the cylinder base after it is fully dried;

[0052] (3) Powder filling: pour nickel-based alloy powder into the gap between the inner mold ...

Embodiment 2

[0056] The preparation of embodiment 2 bimetal extruder barrel

[0057] Nickel-based alloy powder is selected, and its chemical composition is B: 3.5%, C: 0.9%, Cr: 16%, Si: 4.5%, Fe: 13.0%, W: 5.0%, Ni: 57.1%; the powder specification is 140 / 325 mesh, hardness HRC61. Type 75 is selected as the base body of the cylinder, the diameter of the inner hole is the size of the finished product plus 3.6mm, and the surface roughness is Ra1.6um. The inner mold is designed and processed according to the size of the inner hole. Specifically include the following steps:

[0058] (1) Substrate cleaning: Provide a cylinder substrate and inner mold, and thoroughly clean the surface of the cylinder substrate and inner mold;

[0059] (2) Mold assembly: Brush a layer of high-temperature-resistant paint on the surface of the inner mold, and assemble it with the cylinder base after it is fully dried;

[0060] (3) Powder filling: pour nickel-based alloy powder into the gap between the inner mol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com