Fish head and tail directional conveying device

A technology of conveying device and fish body, which is applied in the field of fish head and tail directional conveying device, can solve the problems of large volume, low conveying efficiency, large floor area, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with accompanying drawing, the present invention will be further explained:

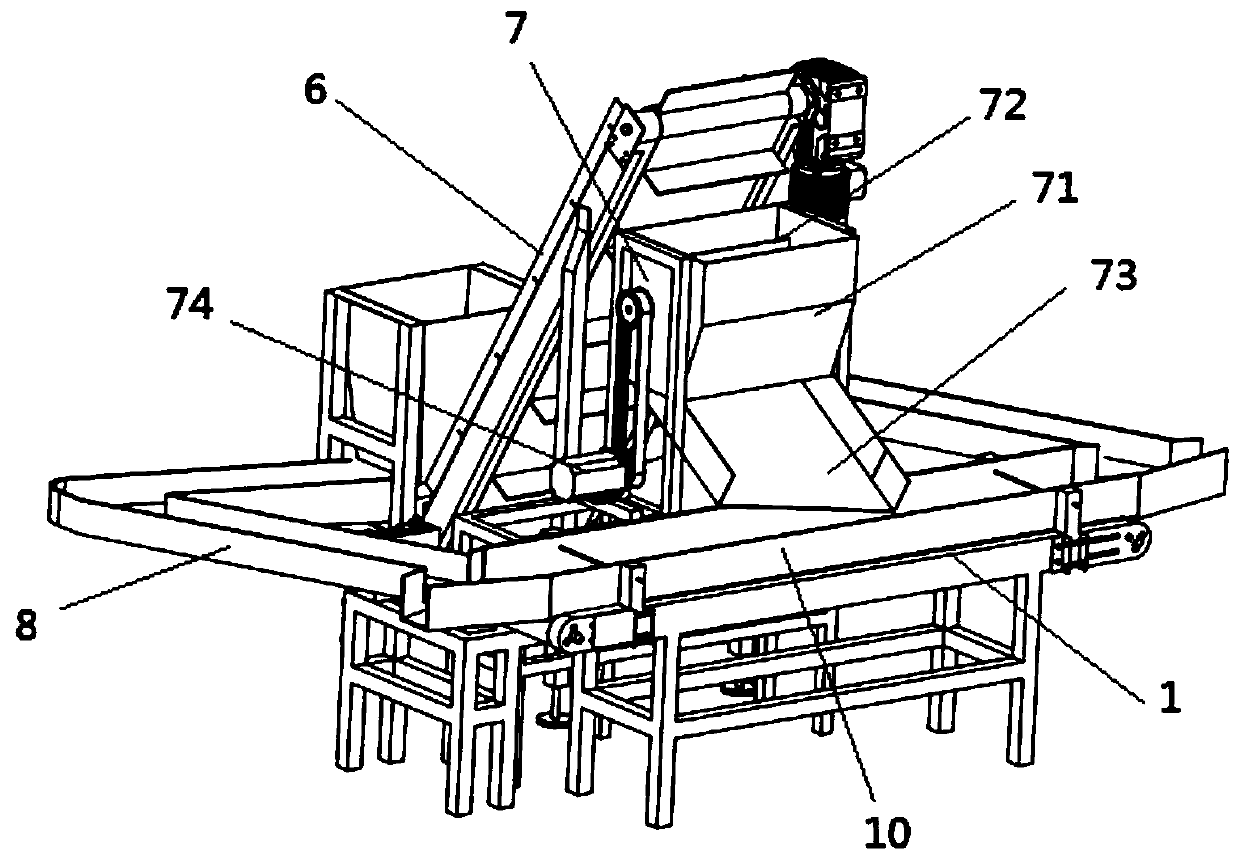

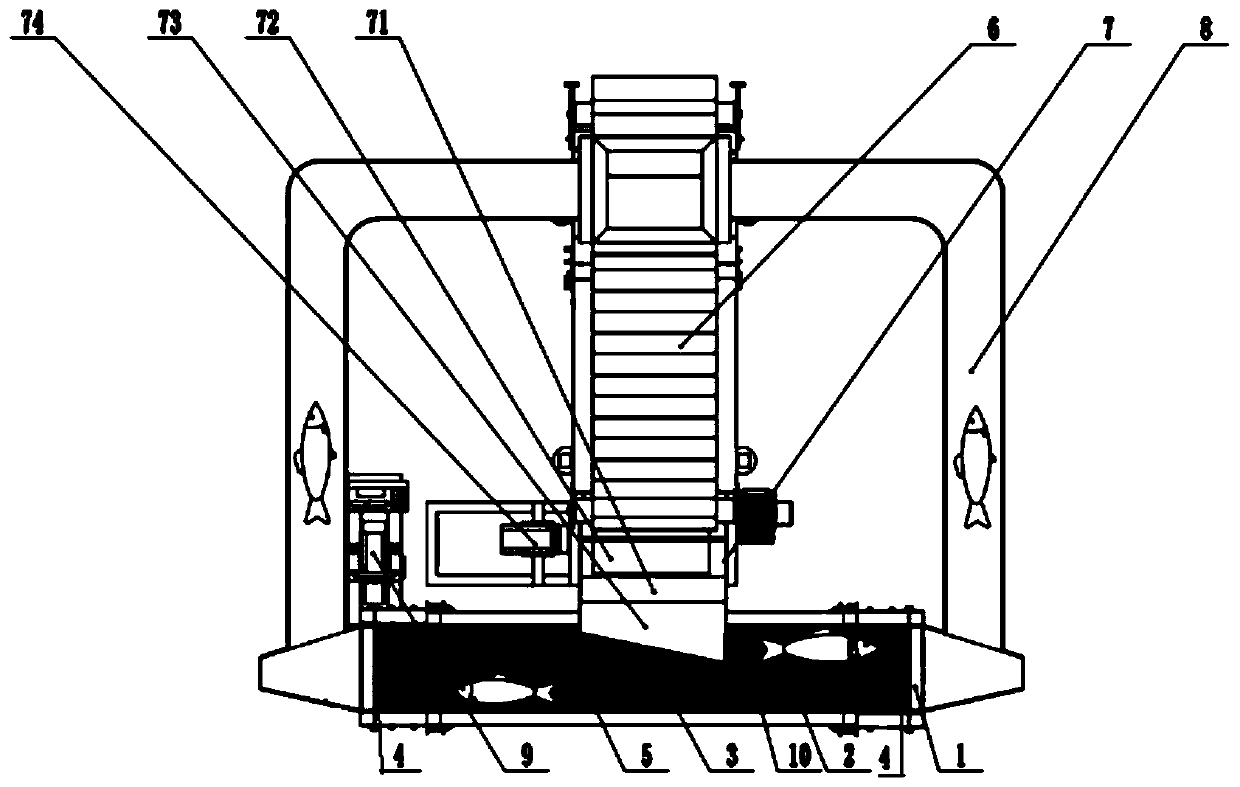

[0037] see figure 1 and figure 2, the present invention includes a fish lifting device 6, a fish separating device 7 and a horizontally reciprocating vibrating table 1 fixed by bracket components.

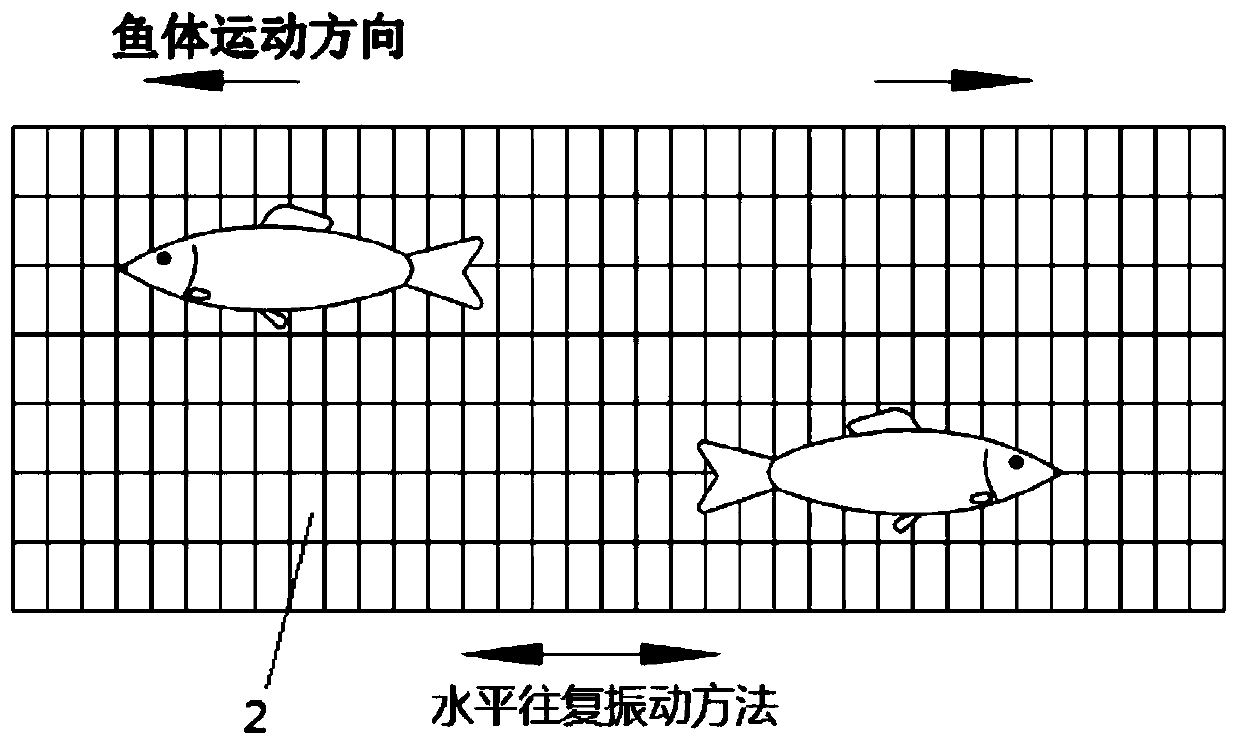

[0038] Wherein, the fish body lifting device 6 can be a lifting conveyor belt or other conveying structures, and its purpose is to replace manual labor to lift the fish body into the fish body separation device 7; the fish body separation device 7 is used to release the fish body In the feeding area 3 of the directional conveyor belt 2 on the horizontal reciprocating vibrating table top 1, so the discharge end of the chute 73 of the fish body separating device 7 should be positioned above the feeding area of the fish body separating device. In order to realize fast and uniform feeding and avoid fish bodies falling into the feeding area 3 and then piling up, the fish body s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tooth thickness | aaaaa | aaaaa |

| Tooth length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com