Cleaning system of prefabricated part annular production line

A technology of cleaning system and prefabricated components, applied in the field of cleaning system, can solve the problems of incomplete precipitation of concrete, low efficiency, sanitary and dirty production line, etc., and achieve the effect of optimizing the overall cleaning process, reducing occupation and waste, and improving the cleaning process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

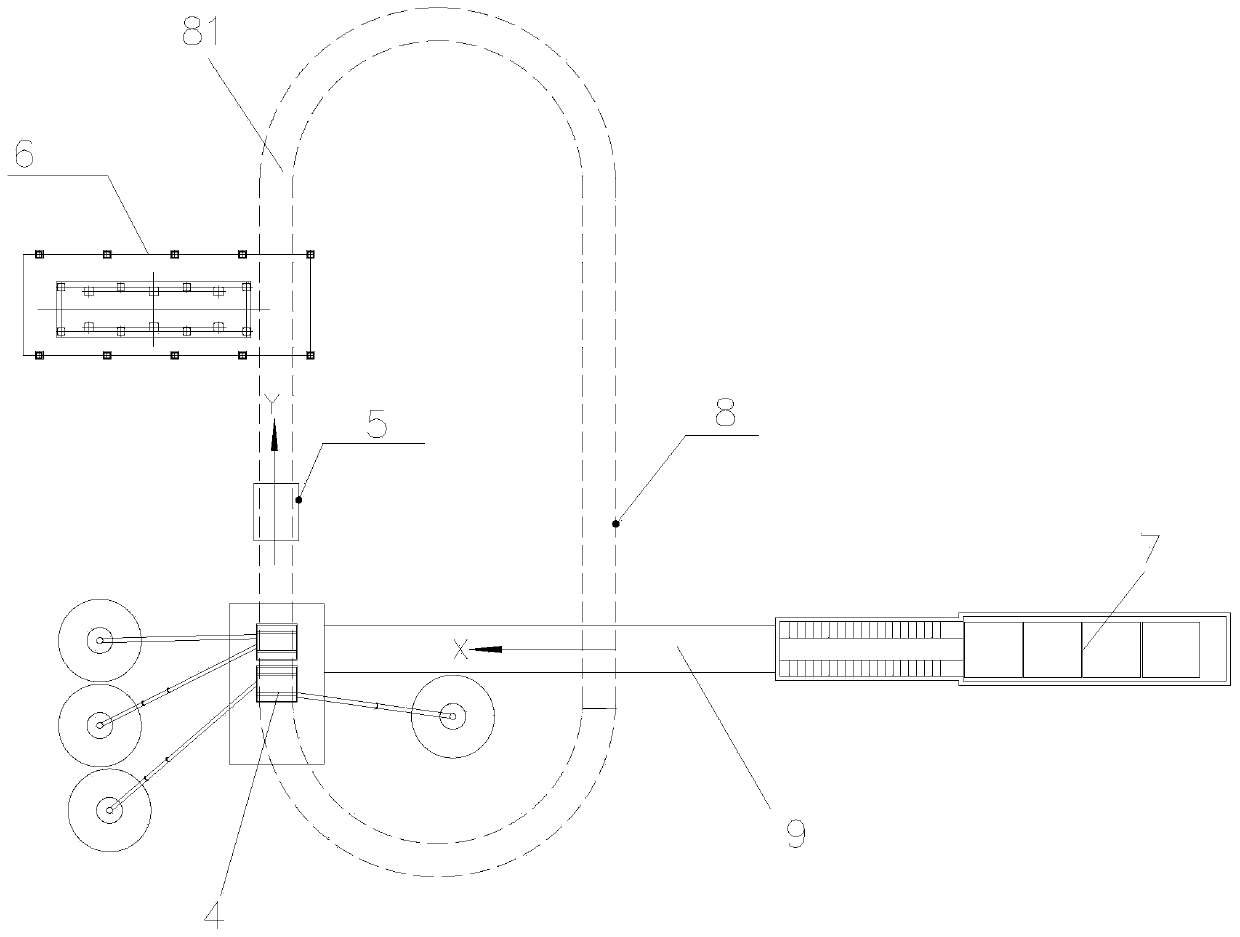

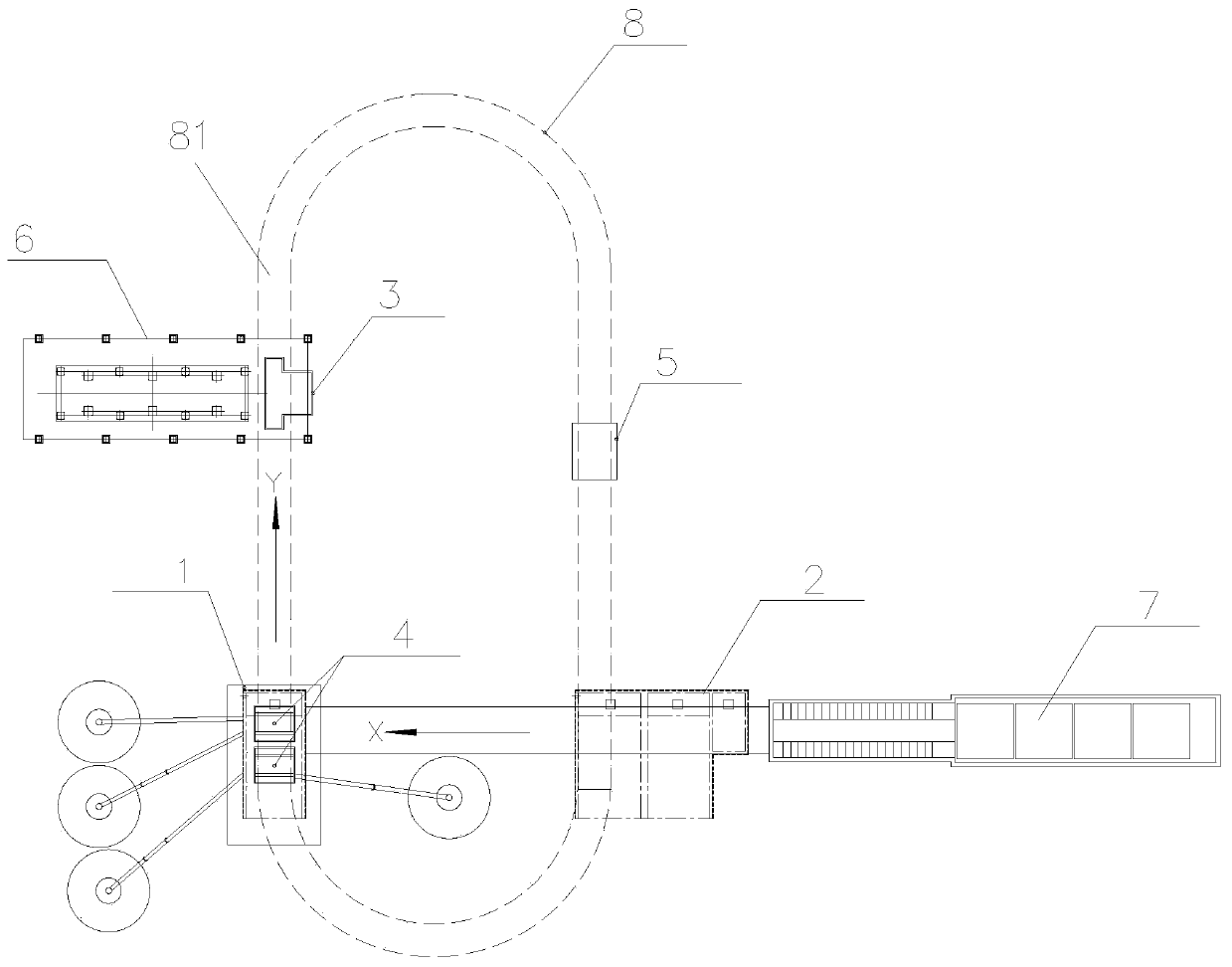

[0044] Such as figure 2As shown, the cleaning system of the circular production line of prefabricated components in this embodiment includes a first settling tank 1 for cleaning the hopper of the mixing station host 4, a first settling tank group 2 for cleaning the feeding car 5, And the second settling tank group 3 for cleaning the hopper on the cloth frame 6.

[0045] The first settling tank 1 is located below the main machine 4 of the mixing station, and the first settling tank group 2 is located between the main machine 4 of the mixing plant and the silo 7 of the mixing station and is positioned under the annular feeding rack 8; the first settling tank 1 and the first settling tank The pool groups 2 are communicated with each other through drains 9 .

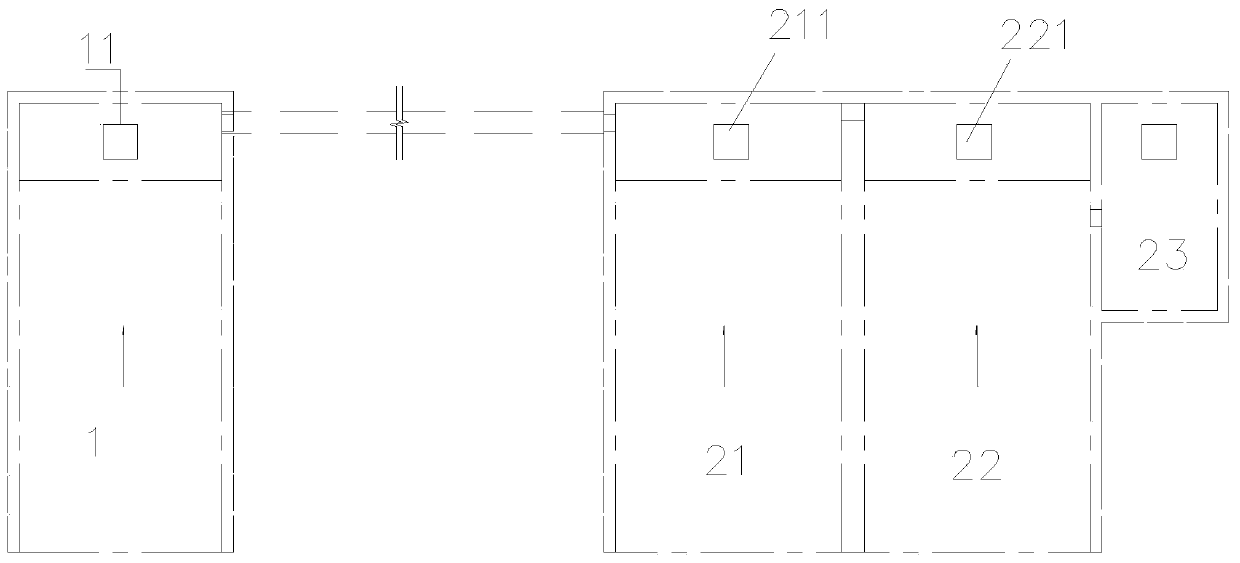

[0046] Such as image 3 As shown, the first settling tank group 2 includes the second settling tank 21, the third settling tank 22 and the fourth settling tank 23 connected in sequence, the first settling tank 1, the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com