Preparation method and application of mixed matrix membrane containing MOF filler

A technology of mixed matrix membrane and matrix, applied in the field of preparation of mixed matrix, can solve the problems of weak bond interaction and interface affecting the performance of mixed matrix membrane, and achieve the effects of enhanced interaction, easy industrial application, and simple and easy preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

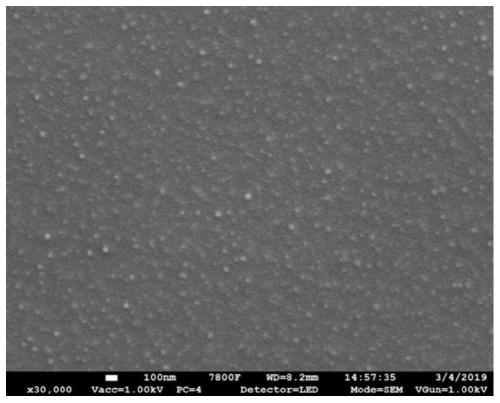

[0033] Add 6.04g of P84 powder into 21.15g of N-methylpyrrolidone solvent, stir and dissolve at 50°C; 0.43g of nickel formate [Ni 3 (HCOO) 6 ] powder was added to 23.04g of N-methylpyrrolidone solvent, stirred at 50°C for 2h, ultrasonicated for 2h, and then [Ni 3 (HCOO) 6 ] / NMP suspension was added to P84 / NMP and stirred at 50°C for 24h, and the resulting solution was ultrasonically defoamed for 2h to obtain a casting solution. Finally, the casting solution was cast on a glass plate at 60° C., scraped with a 400 μm scraper to form a film, and then allowed to stand for 24 hours. The film was removed from the glass plate and dried under vacuum at 150 °C for 48 h to obtain [Ni 3 (HCOO) 6 ] / P84 mixed matrix membrane, its cross-sectional structure is shown in the attached figure 2 , as can be seen from the figure, [Ni 3 (HCOO) 6 ] The particles are uniformly dispersed in the polymer matrix, and the bonded interface is free of defects. The gas separation performance test (0...

Embodiment 2

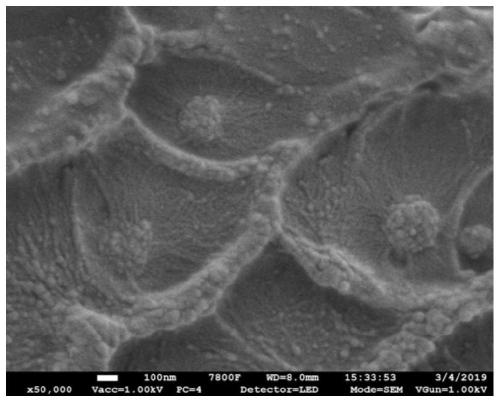

[0037] Add 6.00g of P84 powder into 16.15g of N-methylpyrrolidone solvent, stir and dissolve at 50°C; 0.90g of nickel formate [Ni 3 (HCOO) 6 ] powder was added to 28.44g of N-methylpyrrolidone solvent, stirred at 50°C for 2h, ultrasonicated for 2h, and then [Ni 3 (HCOO) 6 ] / NMP suspension was added to P84 / NMP and stirred at 50°C for 24h, and the resulting solution was ultrasonically defoamed for 2h to obtain a casting solution. Finally, the casting solution was cast on a glass plate at 60° C., scraped with a 400 μm scraper to form a film, and then allowed to stand for 24 hours. The film was removed from the glass plate and dried under vacuum at 150 °C for 48 h to obtain [Ni 3 (HCOO) 6 ] / P84 mixed matrix membrane, its cross-sectional structure is shown in the attached image 3 , as can be seen from the figure, [Ni 3 (HCOO) 6] The particles are uniformly dispersed in the polymer matrix, and the bonded interface is free of defects. The gas separation performance test (0.5...

Embodiment 3

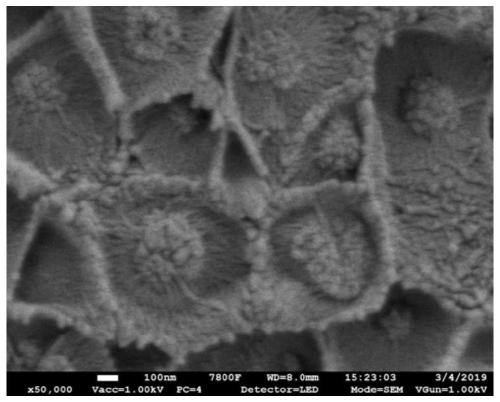

[0041] 6.02g P84 was added to 19.81g N-methylpyrrolidone solvent, stirred and dissolved at 50°C; 1.51g nickel formate [Ni 3 (HCOO) 6 ] powder was added to 27.02g of N-methylpyrrolidone solvent, stirred at 50°C for 2h, ultrasonicated for 2h, and then [Ni 3 (HCOO) 6 ] / NMP suspension was added to P84 / NMP and stirred at 50°C for 24 hours, and the resulting solution was ultrasonically defoamed for 2 hours to obtain a casting solution. Finally, the casting solution was cast on a glass plate at 60° C., scraped with a 400 μm scraper to form a film, and then allowed to stand for 24 hours. The film was removed from the glass plate and dried under vacuum at 150 °C for 48 h to obtain [Ni 3 (HCOO) 6 ] / P84 mixed matrix membrane. The gas separation performance (0.5MPa, 30°C) was tested by the constant volume change pressure method, and the test results are shown in Table 4.

[0042] Table 4

[0043]

[0044] From Comparative Example 1 and Example 1-Example 3, it can be seen that co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com