Shell cleaning control system for numerical control machine tool

A technology of CNC machine tools and control systems, which is applied in the direction of manufacturing tools, metal processing machinery parts, maintenance and safety accessories, etc., can solve problems such as unfavorable cleaning of CNC machine tools, time-consuming and laborious cleaning, troublesome cleaning of CNC machine tool shells, etc., to improve cleaning efficiency As well as the cleaning effect and the effect of reducing the difficulty of cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

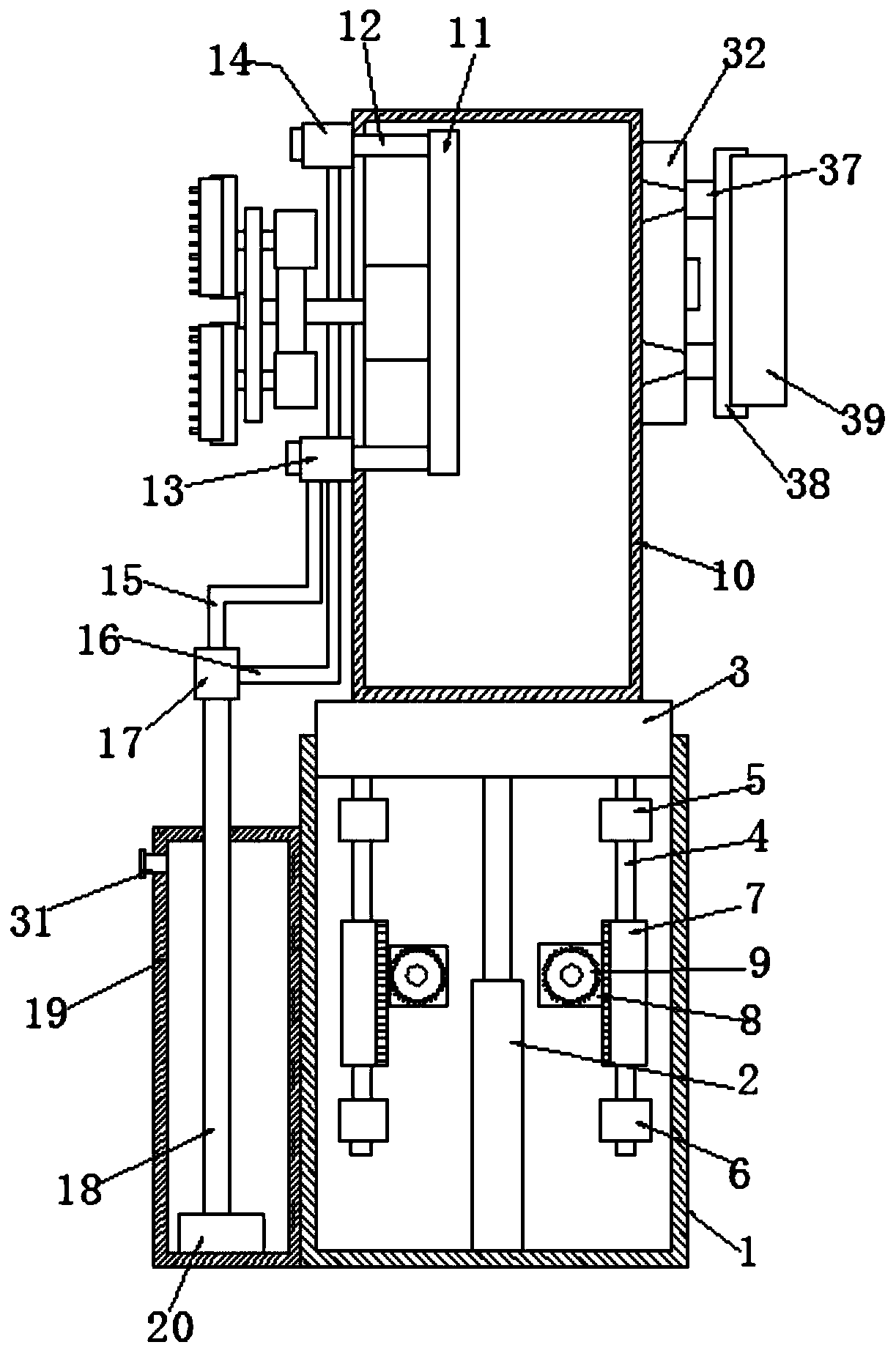

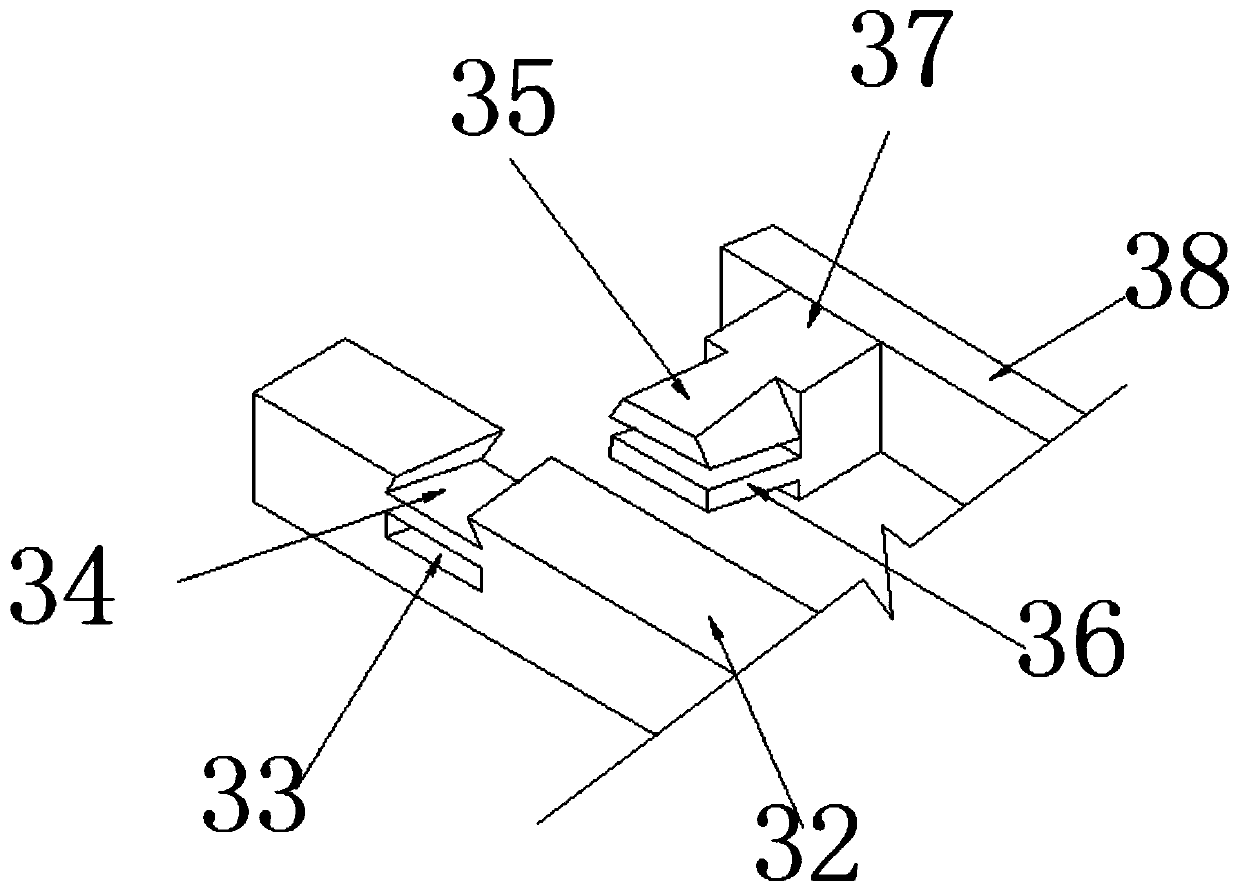

[0031] Embodiment one, such as Figure 1-2 As shown, a shell cleaning control system for a numerically controlled machine tool according to an embodiment of the present invention includes a cylinder-1, which is a cavity column, and a telescopic column is longitudinally arranged in the middle of the cylinder-1. 2. The top of the telescopic column 2 is provided with a push plate 3, and the push plate 3 is located at the opening position of the top of the column body 1, and both ends of the bottom of the push plate 3 are provided with support rods 4, so Both ends of the support rod 4 are provided with a limit sleeve 5 and a limit sleeve 6 respectively, wherein the limit sleeve 5 and the limit sleeve 6 are all fixed in the cylinder one 1 Both ends on both sides, both sides support bar 4 is provided with symmetrical half gear 7, and both sides half gear 7 corresponds to the side and is positioned at the middle part of both sides of described cylinder one 1 and is equipped with moto...

Embodiment 2

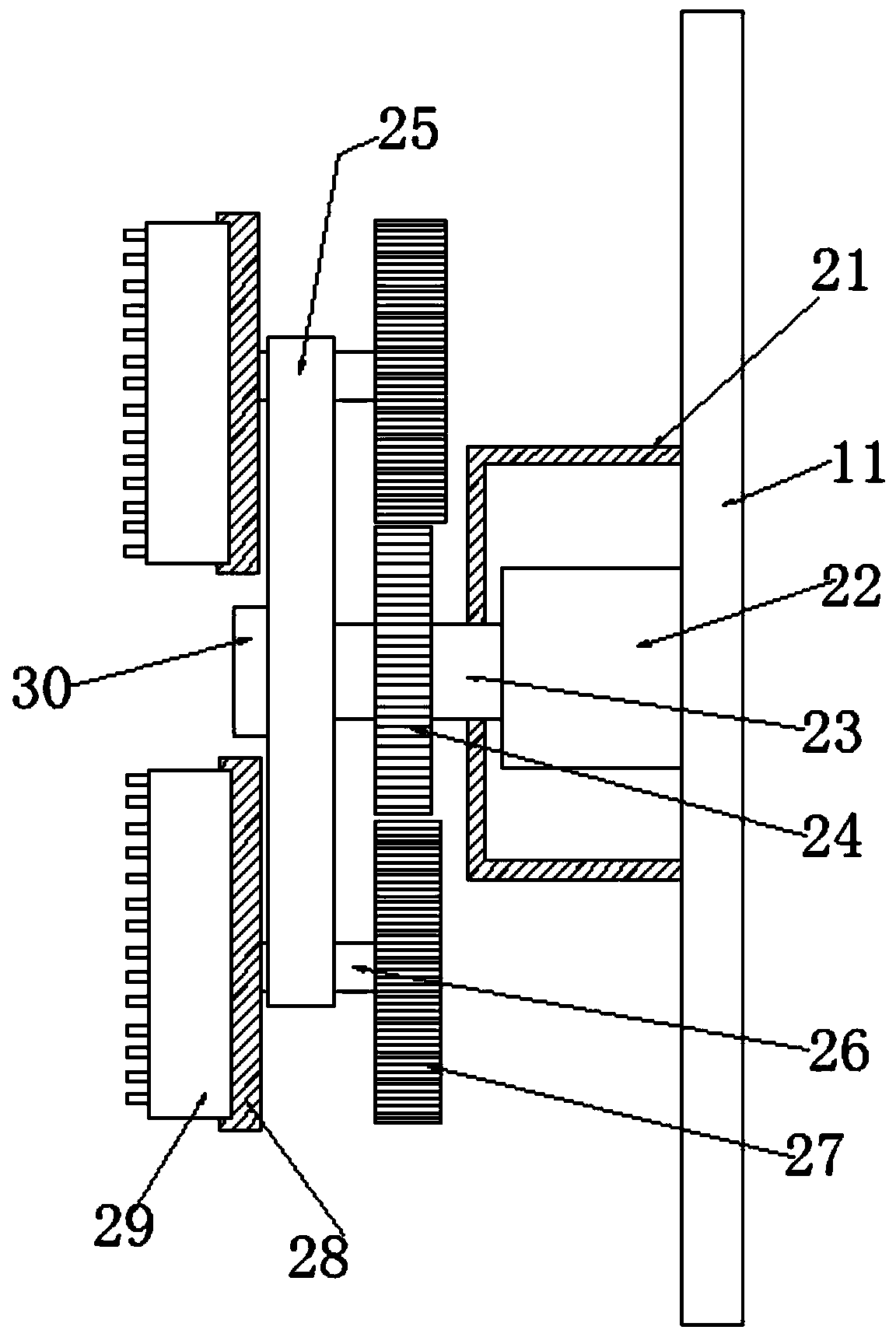

[0034] Embodiment two, such as figure 2As shown, the end of the rotating shaft 1 23 away from the motor 1 22 is sleeved with a limiting block 30 , and the sides of the limiting block 30 are fixed in the middle of the sides of the fixing plate 2 25 .

Embodiment 3

[0035] Embodiment three, such as figure 1 As shown, a water inlet 31 is provided on the top of the side of the water tank 19 away from the cylinder one 1, and a water inlet end cover is provided on the water inlet 31, wherein the diameter of the water inlet 31 is the same as that of the external inlet. The diameter of the water pipe is suitable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com