CNC saw convenient for feeding

An electronic slicing saw and body technology, applied in sawing components, sawing equipment, loading devices, etc., can solve the problems of wasting manpower, heavy wood, and large volume, saving manpower and preventing space occupation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

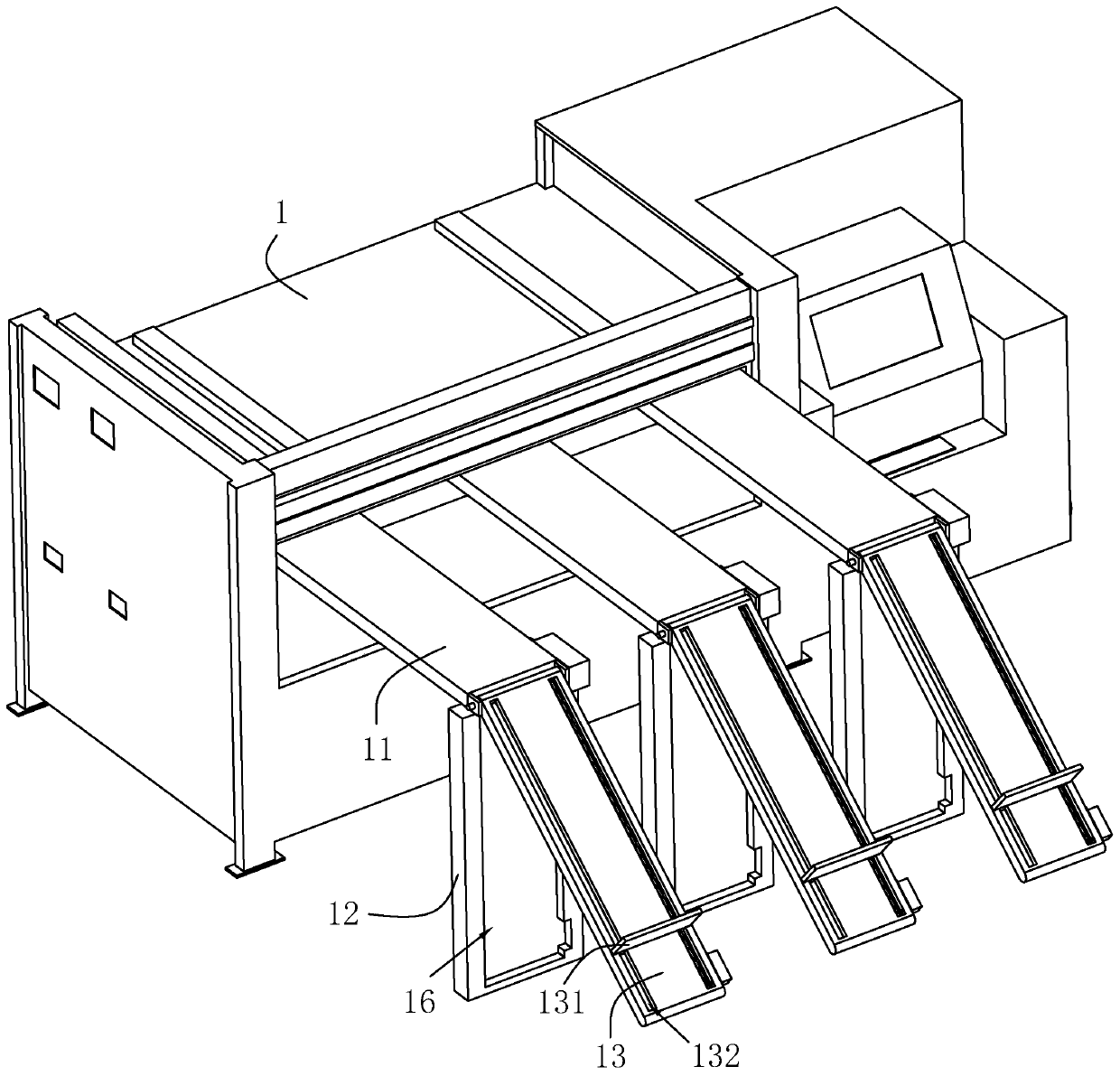

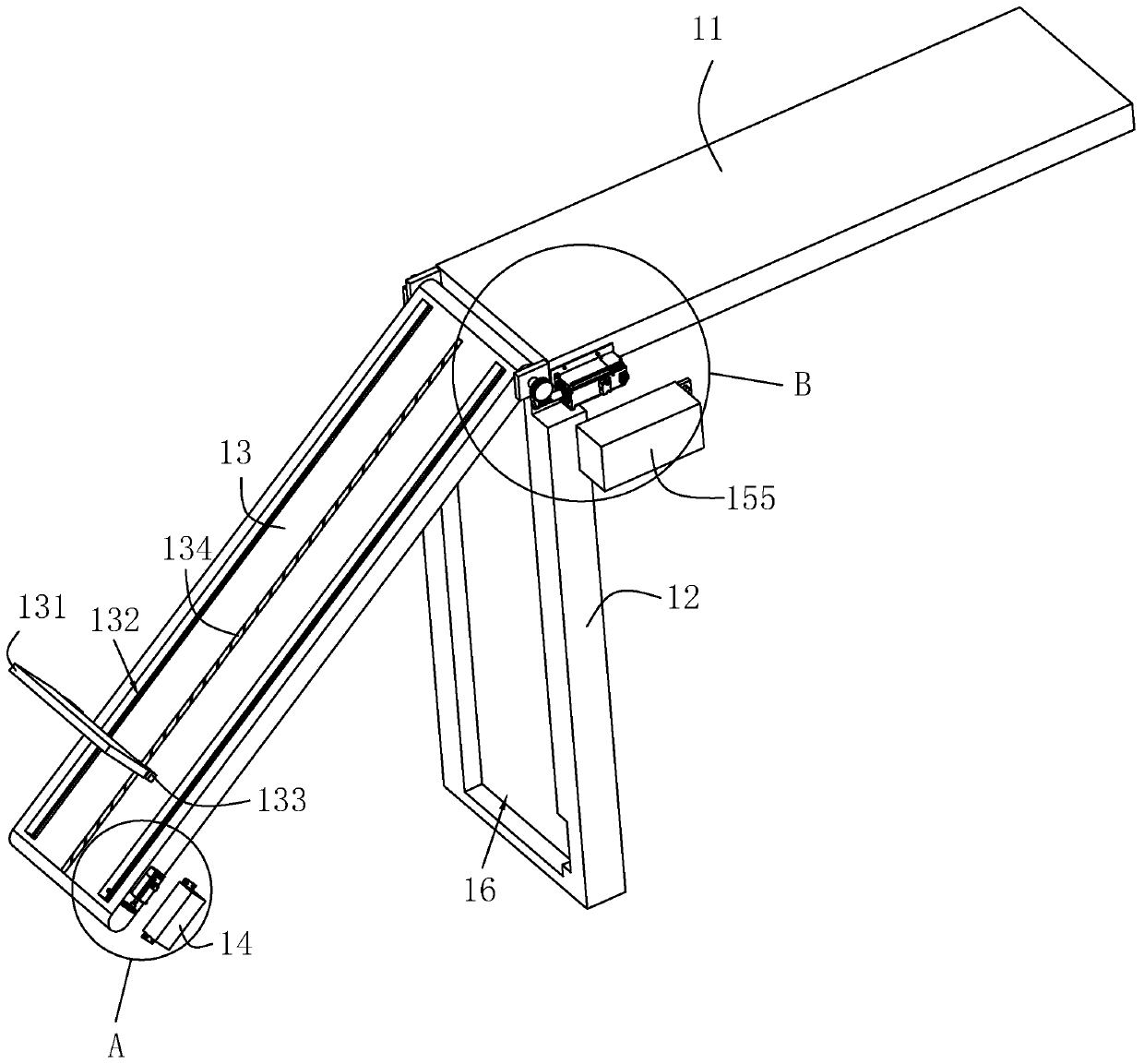

[0032] refer to figure 1 , is an electronic cutting saw that is convenient for feeding disclosed by the present invention, including a body 1, a processing mechanism for processing wood is arranged in the body 1, and a plurality of processing mechanisms for processing wood are arranged on the body 1 at intervals for transporting wood to processing. The delivery platform 11 in the mechanism, a plurality of delivery platforms 11 are located on the same plane, the edge of the delivery platform 11 away from the body 1 is perpendicular to the delivery platform 11 and is provided with a support plate 12, and the support plate 12 is used to support to the ground.

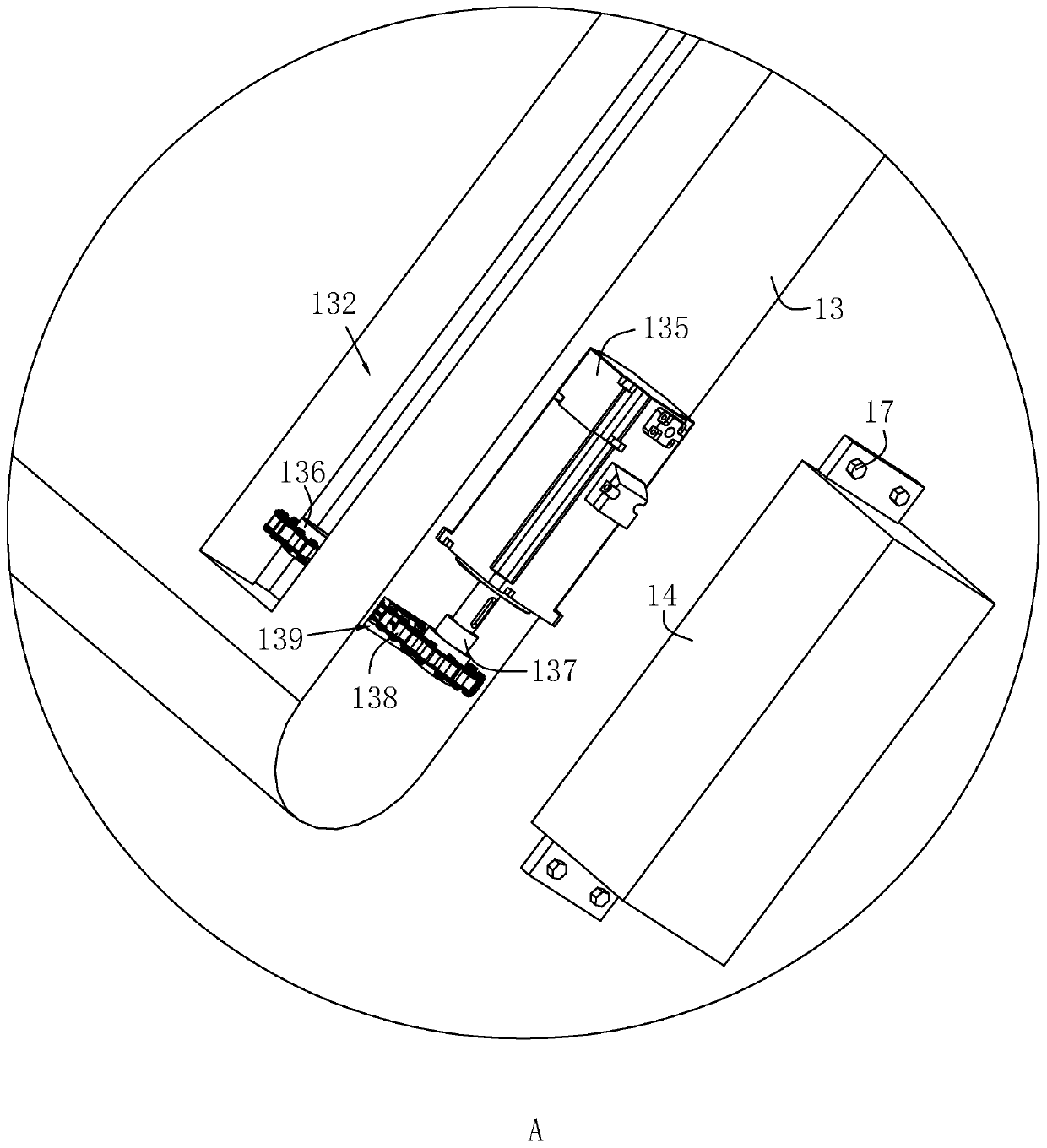

[0033] combine figure 1 and figure 2 , in order to transport the timber to the conveying platform 11, a conveying plate 13 is provided on the edge of the conveying platform 11 away from the body 1 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com