Navy dye device for printing and fabric printing process thereof

A printing process and printing technology, applied in printing, printing machines, rotary printing machines, etc., can solve the problems of reducing work efficiency, long duration, short duration, etc., and achieve the effect of increasing work efficiency and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

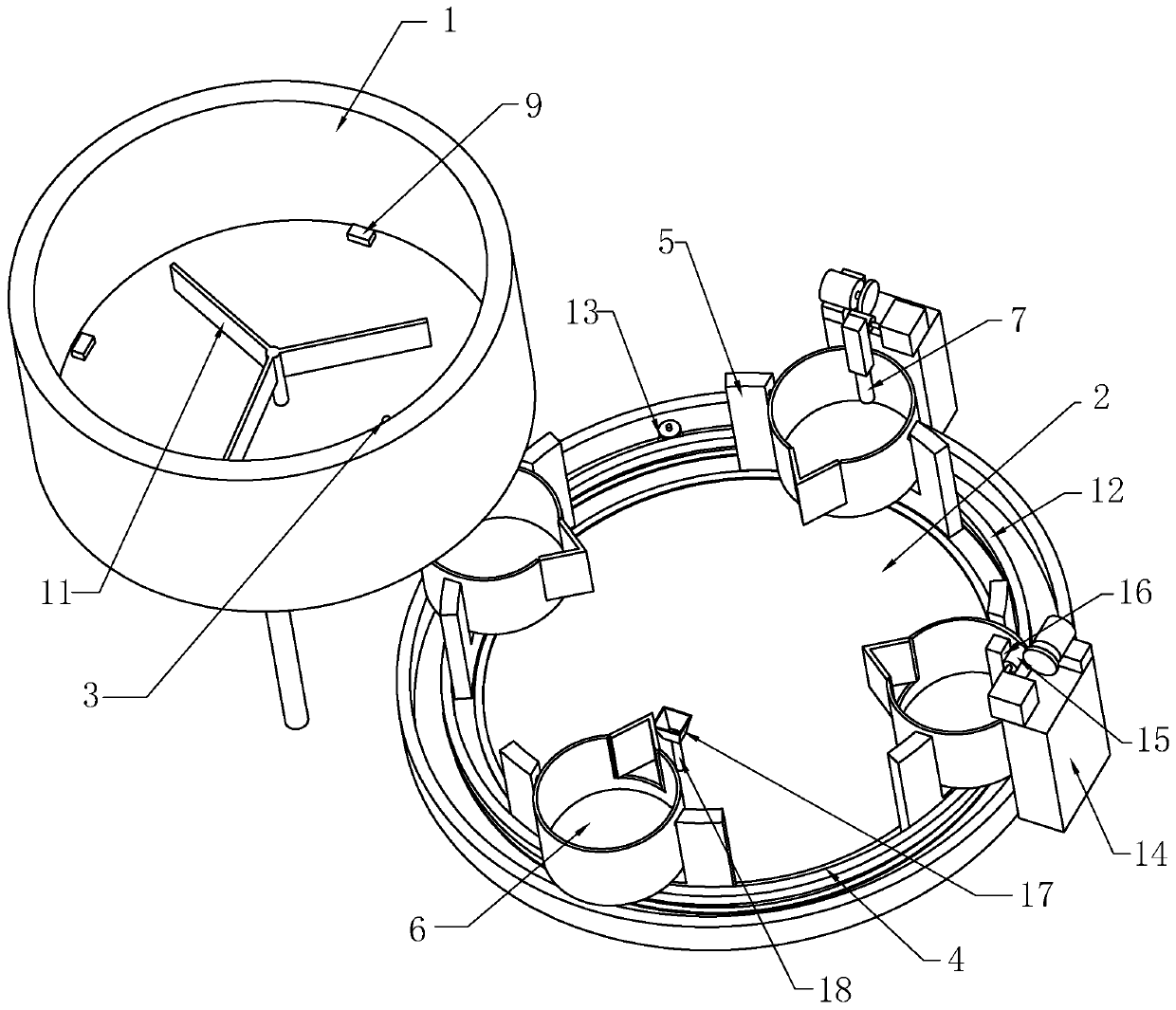

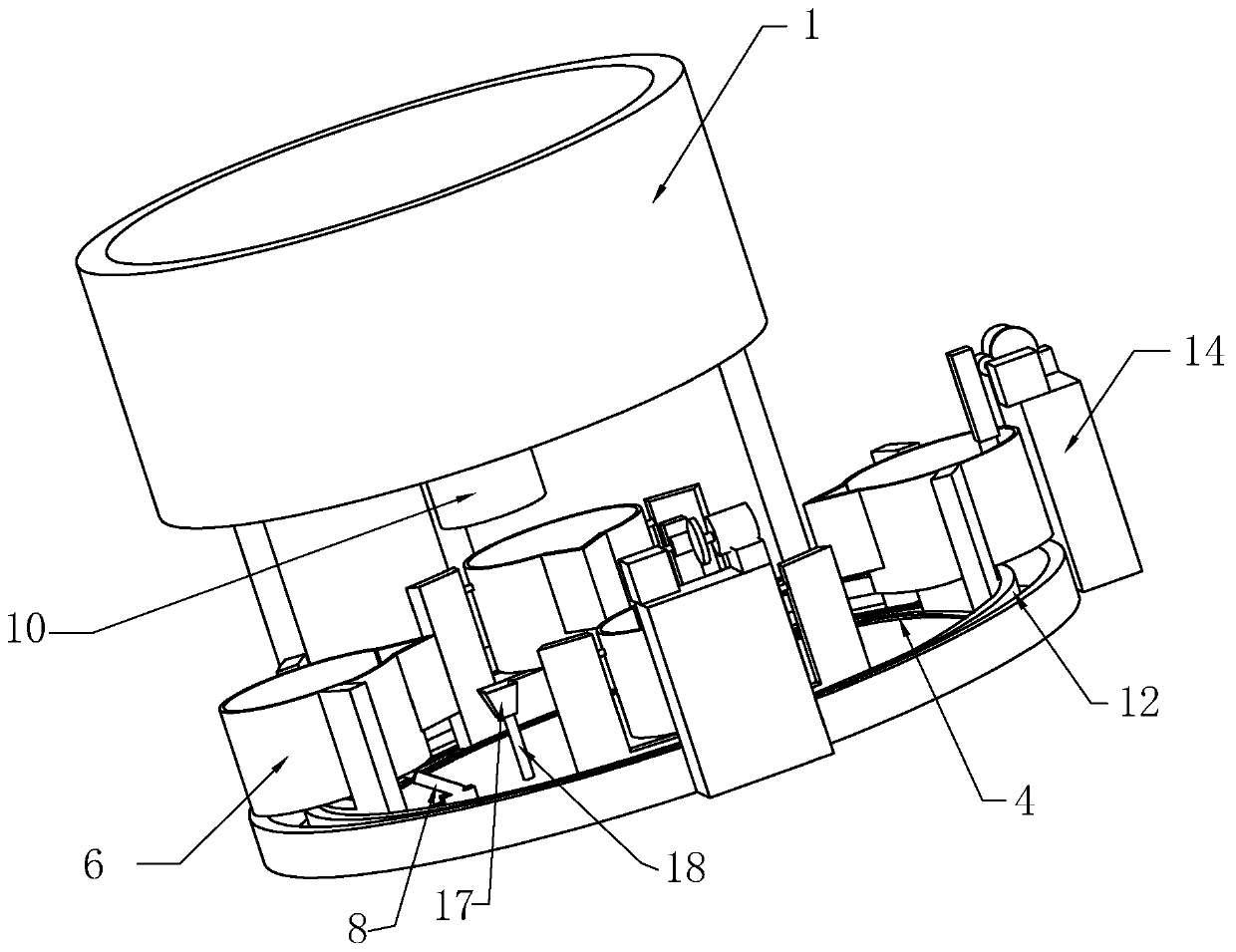

[0027] The following combination figure 1 and figure 2 The present invention is described in further detail.

[0028] A green dye device for printing, comprising an adding pool 1 and a holding tank 2, wherein the adding pool 1 is a circular pool, and a supporting frame is arranged between the bottom of the pool and the ground. A motor 10 is arranged on the bottom surface of the adding pool 1 , the rotating shaft of the motor 10 extends into the adding pool 1 , and a stirring blade 11 is arranged on the rotating shaft. The inner wall of the adding pool 1 is provided with a plurality of heating devices, the heating device can be an electric heating tube 9, and a control box for controlling the electric heating tube 9 can be set on the outer wall of the adding pool 1 to switch the electric heating tube 9 on and off. Or switch on and off by manually plugging and unplugging the power supply.

[0029] The bottom of the adding pool 1 is provided with an opening and closing openin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com