Stay cable viewable intelligent beam end sealing waterproof cap structure

A waterproof cap and stay cable technology, which is applied to bridges, bridge parts, bridge construction, etc., can solve problems such as damage to the sealing performance and the impossibility of accurate detection of the sealing effect of the waterproof cap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

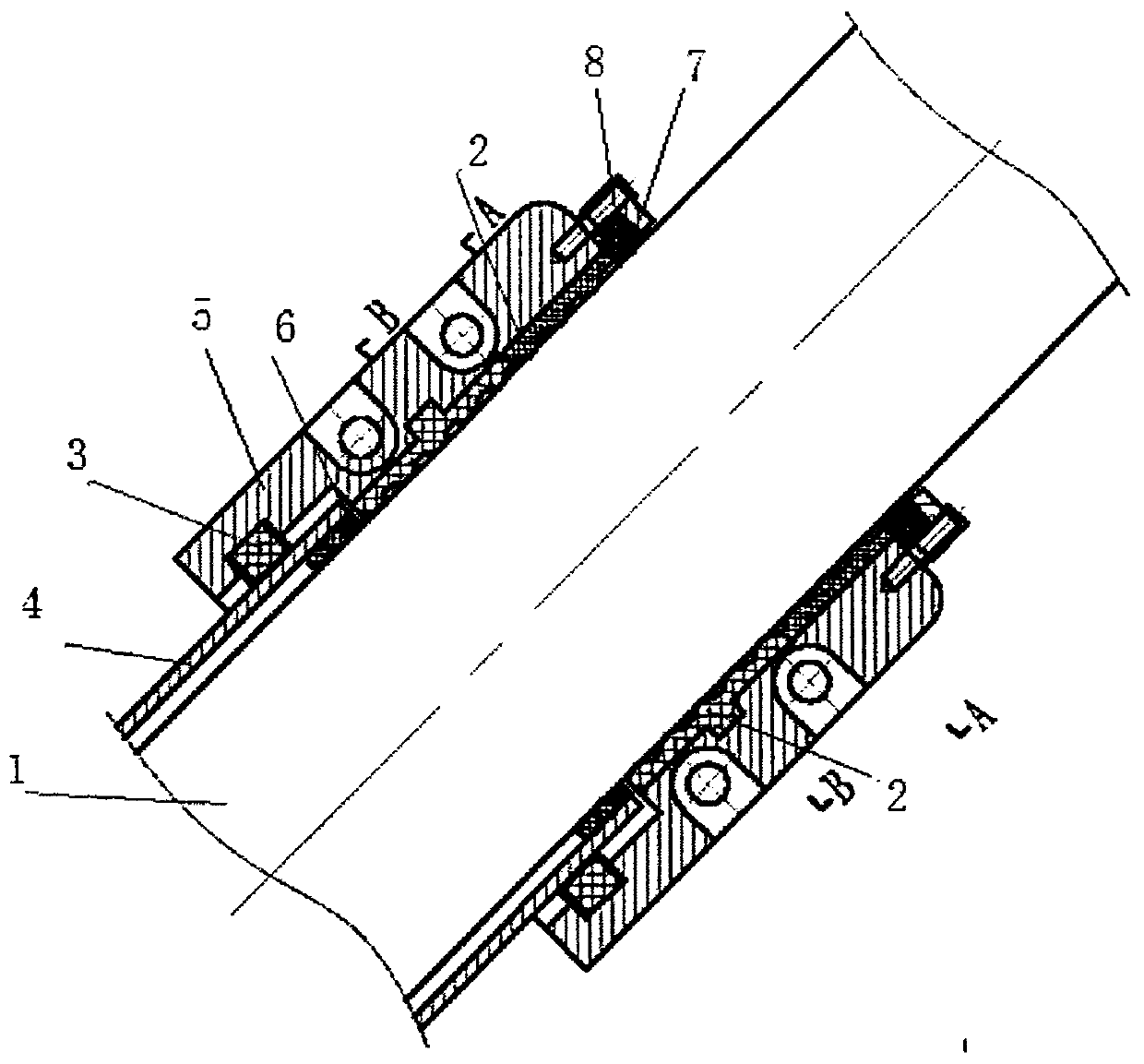

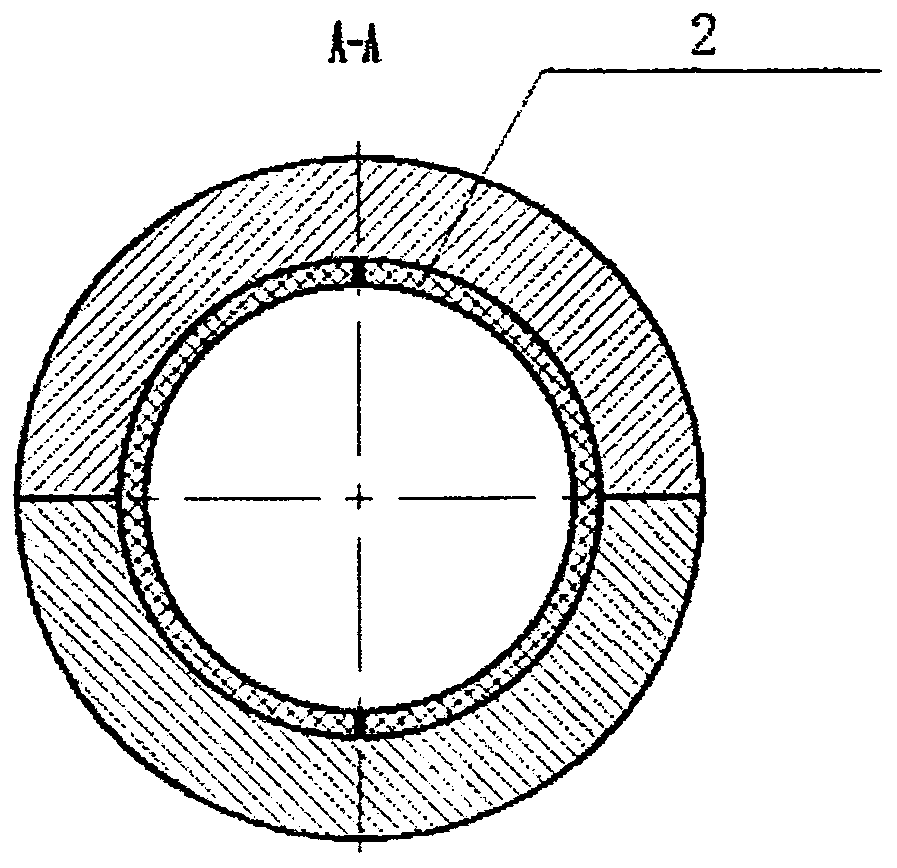

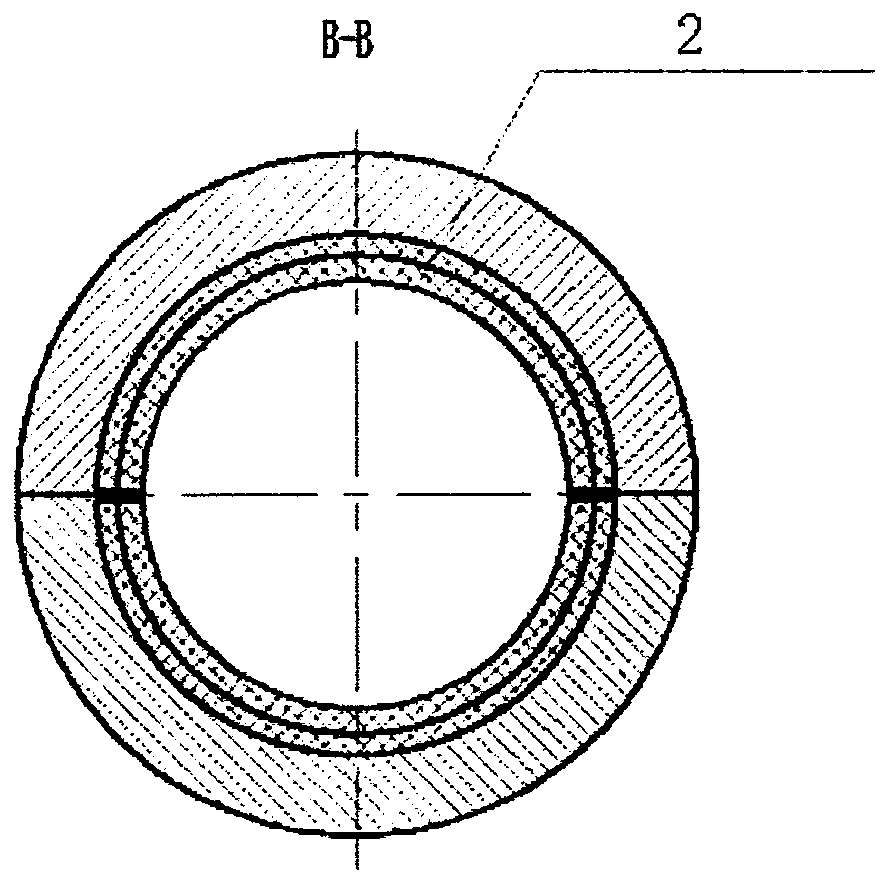

[0028] A stay cable inspectable beam end sealing waterproof cap, which is arranged at the front nozzle of the waterproof cover 4, and includes a waterproof cap body 5, which is made of carbon steel or stainless steel, or further adopts hot-dip galvanizing and paint anti-corrosion coating . The body 5 of the waterproof cap is a Hover combination structure, the inner peripheral wall of the rear end of the waterproof cap is provided with a step hole, the front end of the waterproof cover 4 extends into the step hole, and a first seal is set in the axial gap between the step hole and the waterproof cover 4 Ring 3, and a sealing ring is set between the front end of the waterproof cover and the gap between the cable body 1 and the outermost side is filled with sealant 6.

[0029] The front end of the waterproof cover is provided with a sealing head 7, the sealing head 7 has an axially formed flange, and the flange cooperates with the sealing gasket 10 to lock the sealing head at the...

Embodiment 2

[0035] The difference from Example 1 is that there is a visible hole on the body of the waterproof cap in this embodiment, and a transparent plate is arranged on the visible hole to form a visible window 9. The visible hole covers the step hole, and it can be detected at any time whether there is water seeping into the waterproof cover.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com