Combined composite cylinder buoyancy tank foundation structure and construction method thereof

A technology of floating box foundation and construction method, which is applied in the direction of foundation structure engineering, construction, etc., can solve the problems of large diameter of cylindrical foundation, difficult application in areas with soil distribution and rock distribution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

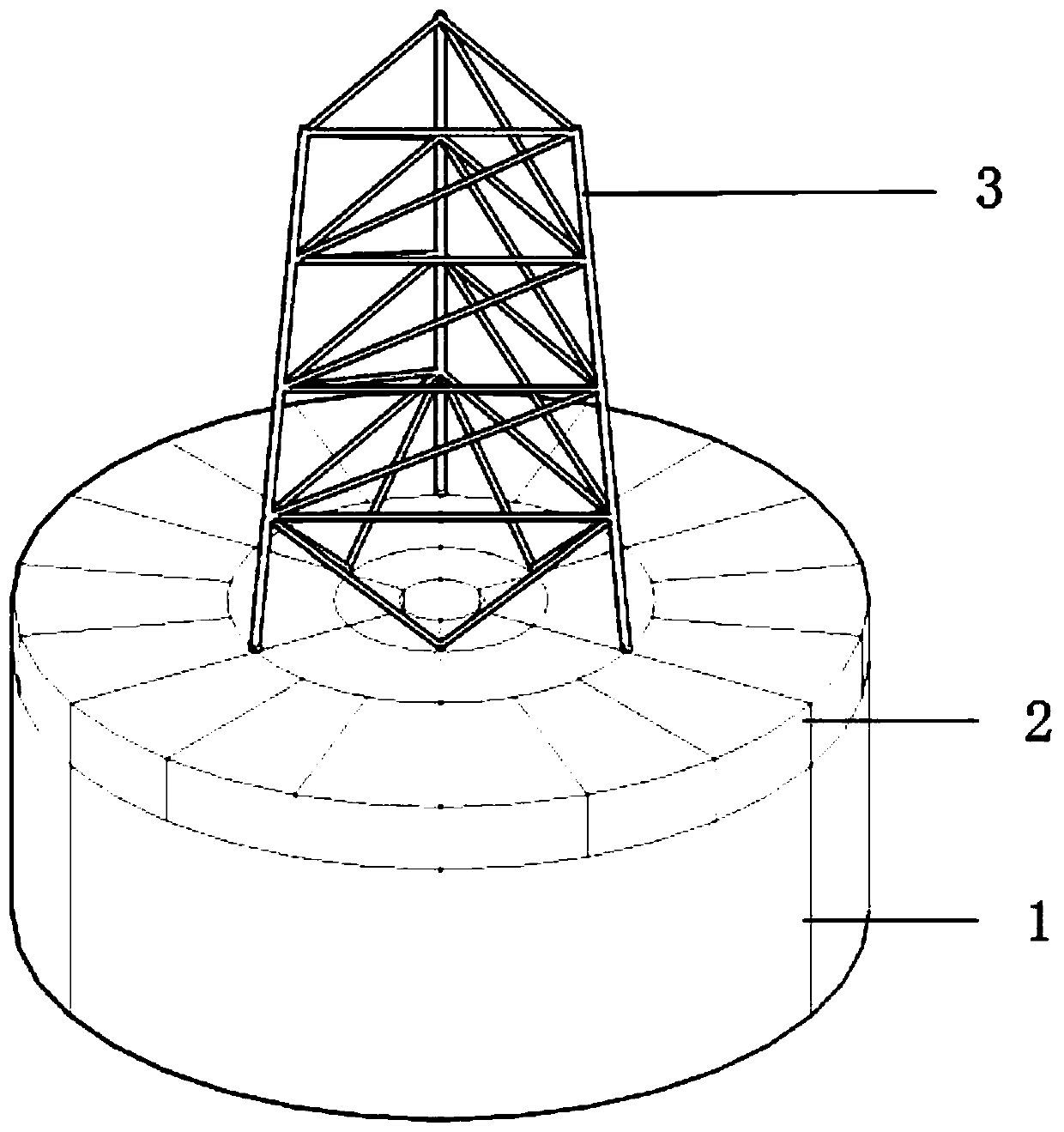

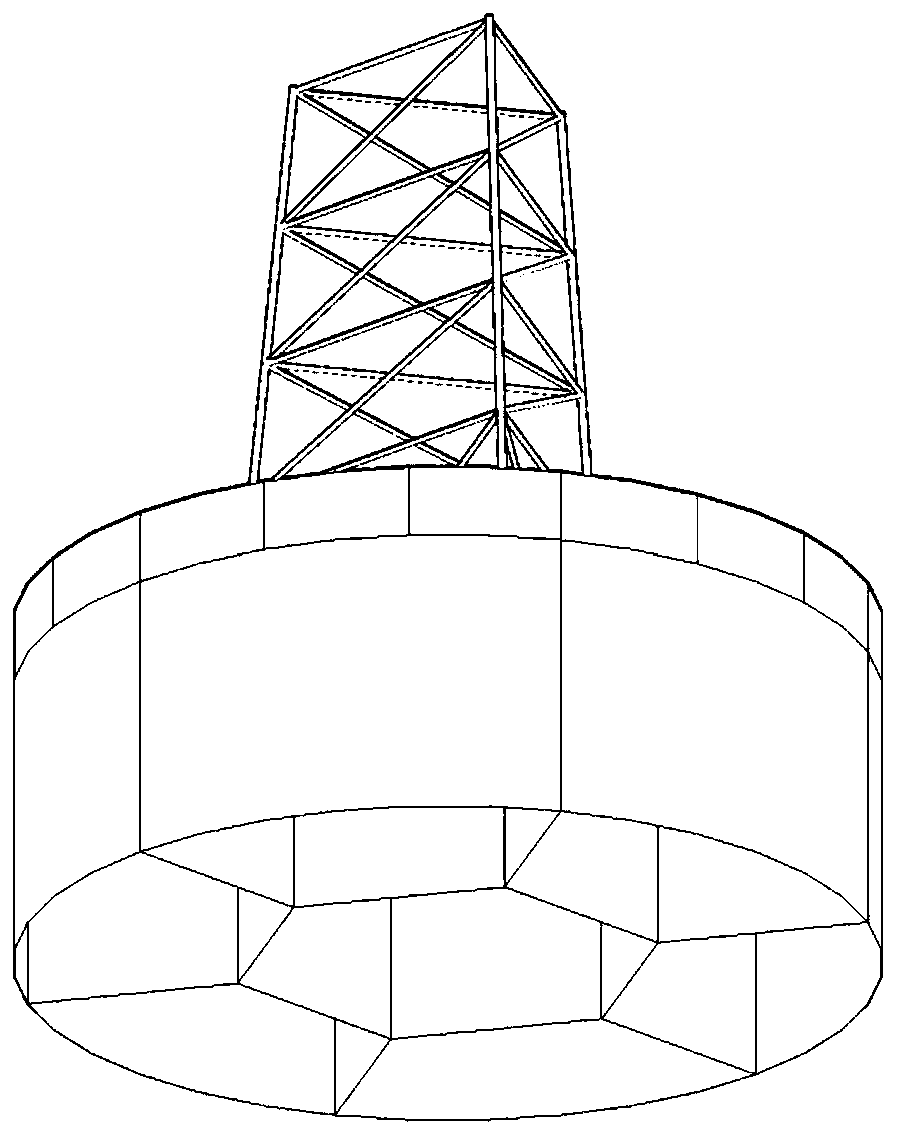

[0037] Such as Figure 1 to Figure 4 As shown, this embodiment discloses a combined composite drum buoyant foundation structure, which mainly includes a steel drum structure 1 with multiple cabins, a steel buoyant tank 2, and a transition section tower 3.

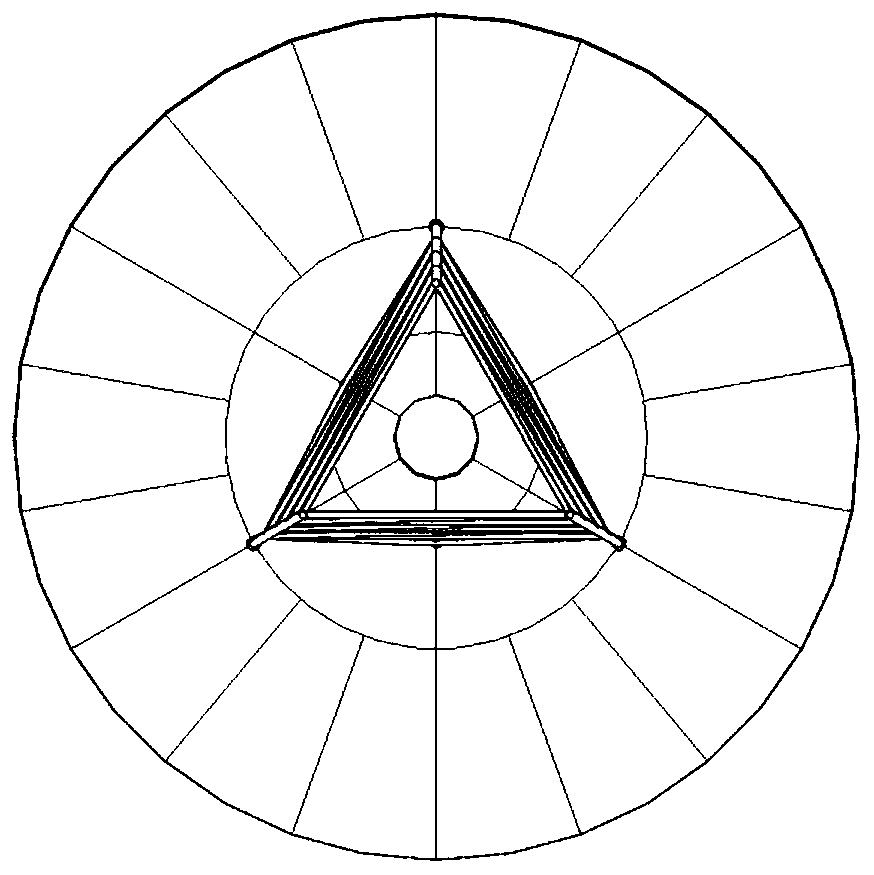

[0038] The steel cylinder structure 1 is a steel cylindrical structure open up and down, with a diameter of 10-50m and a height of 1 / 4 to 1 / 2 of its diameter. The interior of the steel cylinder structure 1 is divided into seven compartments by twelve identical steel plates, including a regular hexagonal middle compartment and six side compartments surrounding the middle compartment. Each side tank of the steel cylinder structure 1 is provided with an air pressure sensor, which is used to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com