Automobile air conditioner compressor and tilting tray structure thereof

A technology for automotive air conditioners and compressors, which is applied in mechanical equipment, machines/engines, liquid variable capacity machines, etc. It can solve problems such as troublesome installation, and achieve the effects of convenient assembly, stable interference effect, and stable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

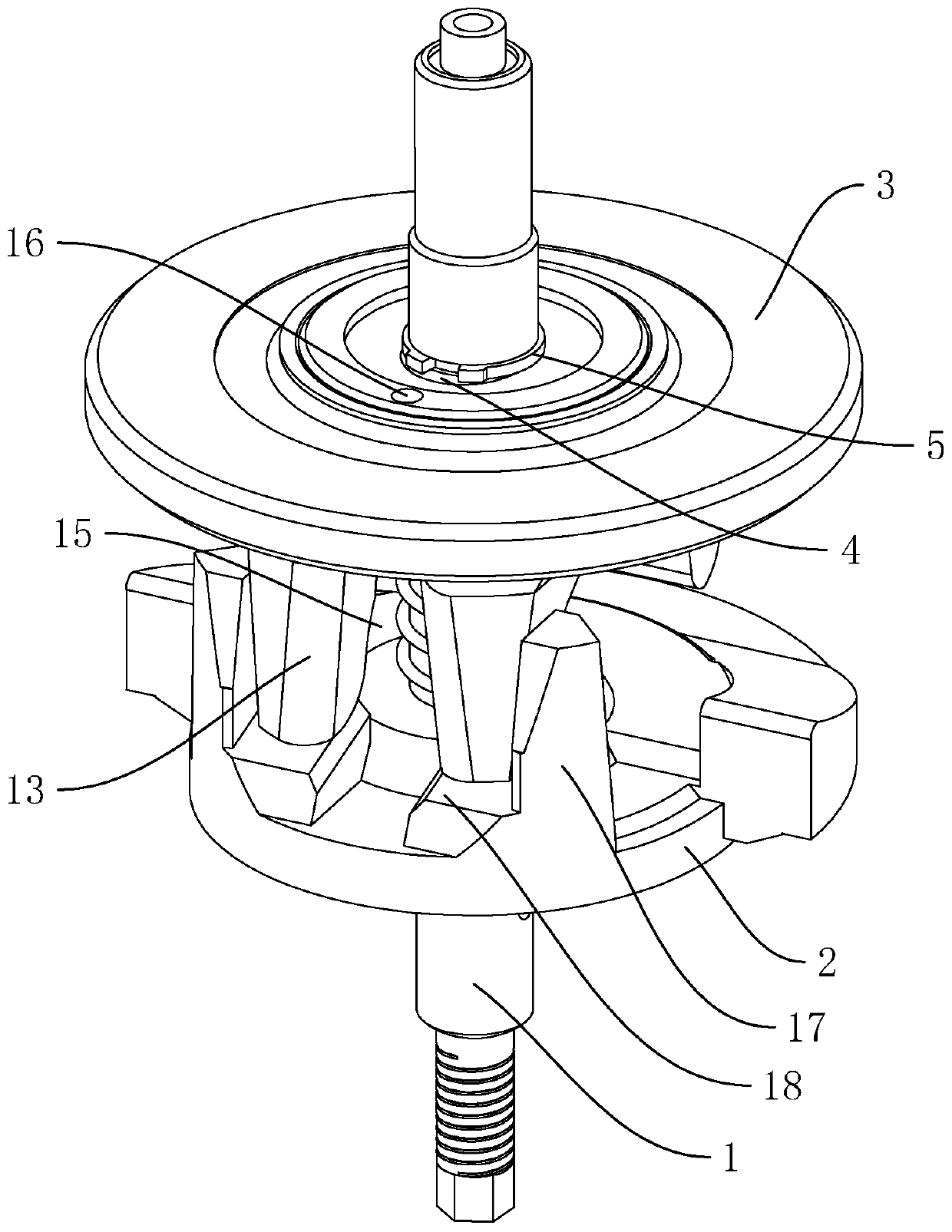

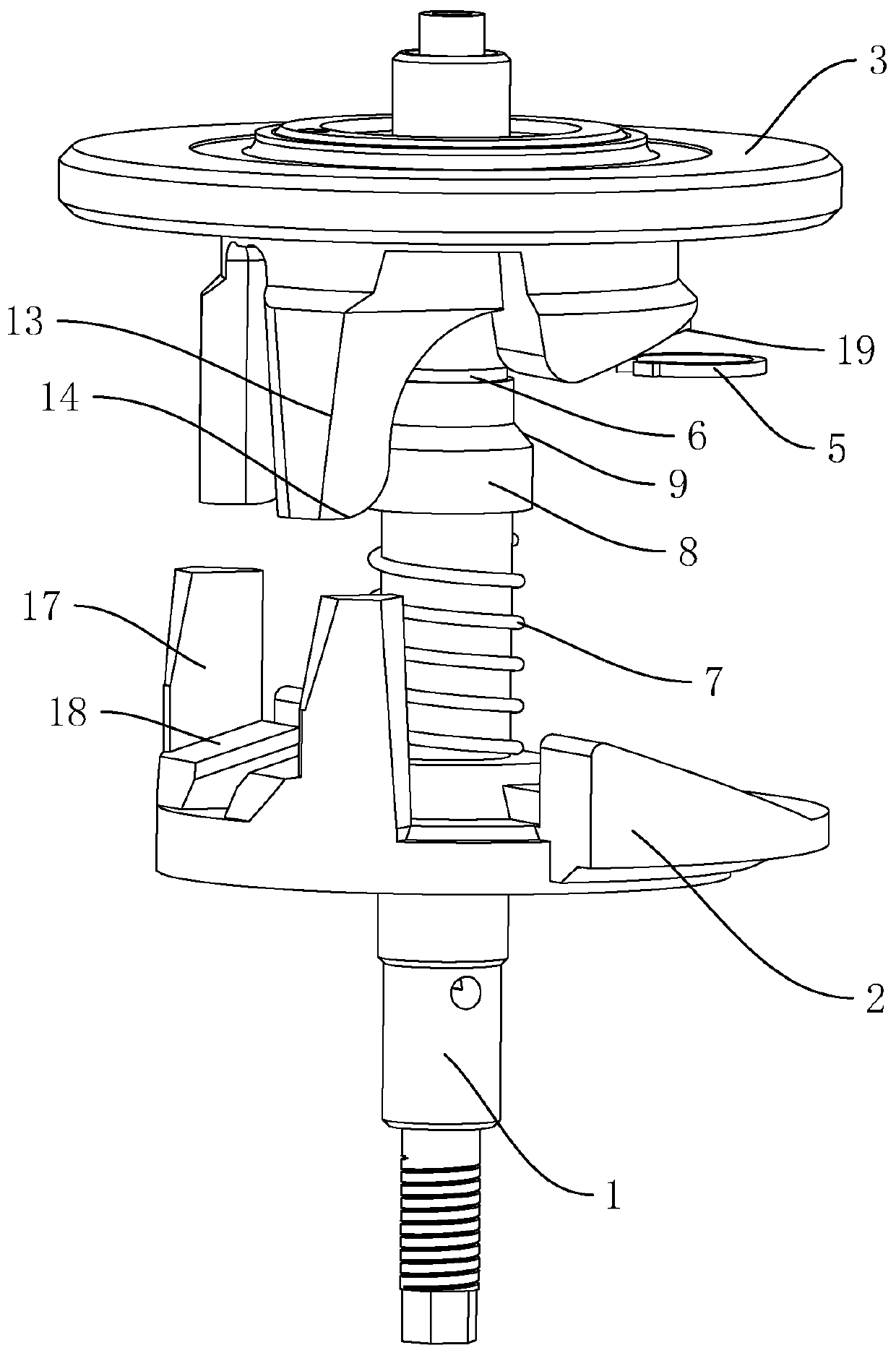

[0040] A swash plate structure of an automobile air-conditioning compressor, such as figure 1 As shown, it includes a main shaft 1 , a rotary arm 2 and a swash plate 3 arranged on the main shaft 1 . The pivoting arm 2 is coaxially fixed on the main shaft 1, and the center of the swash plate 3 is provided with an equi-cylindrical oblique hole 4 for the main shaft 1 to pass through.

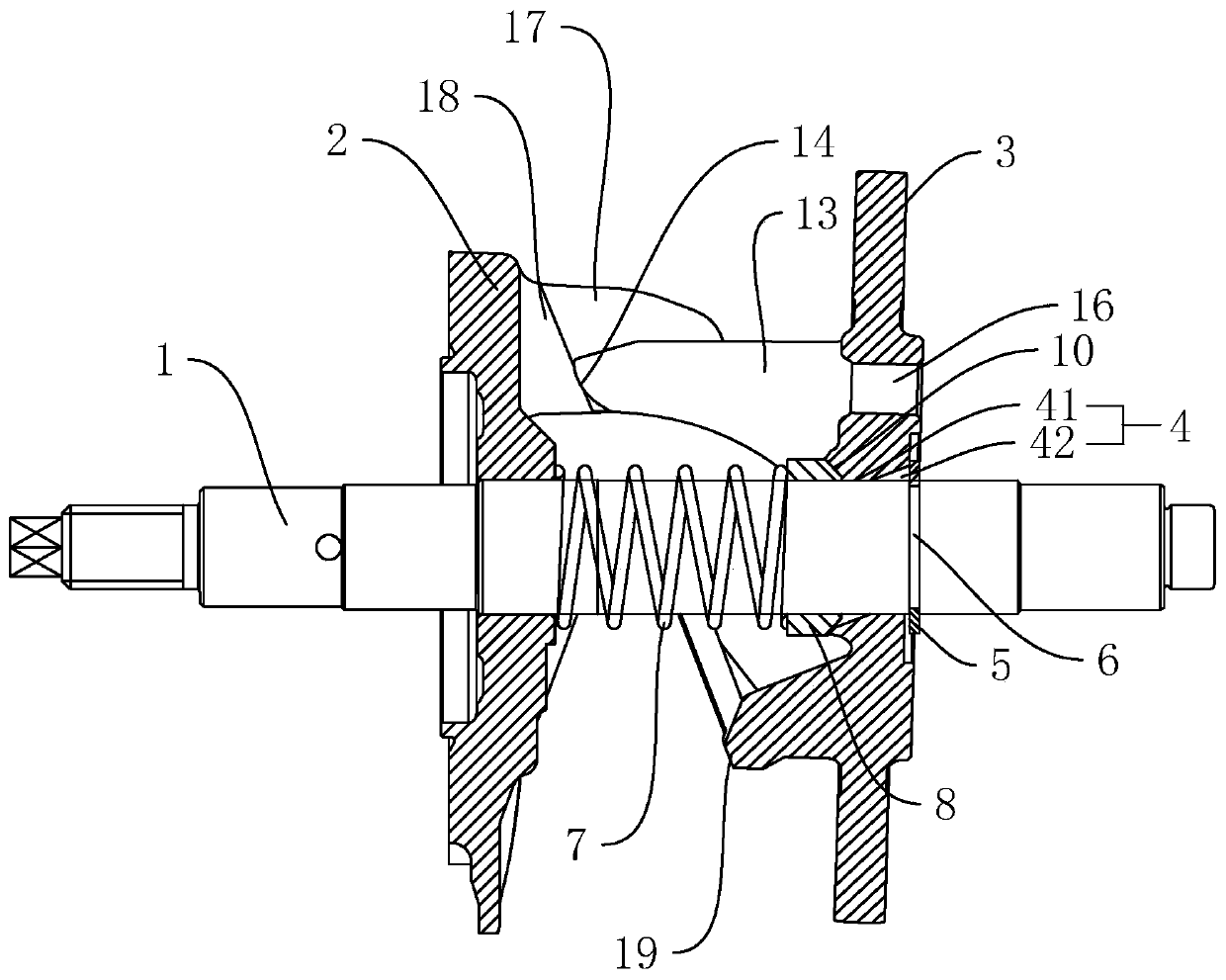

[0041] like figure 1 , image 3As shown, the equi-cylindrical oblique hole 4 includes a mounting hole 41 opened at the axial center of the swash plate 3 for the main shaft 1 to pass through, and two relief grooves 42 opened at both axial ends of the mounting hole 41 . The two relief grooves 42 are respectively located in the opposite direction of the inner wall of the installation hole 41, so that the two relief grooves 42 are respectively located on the radial sides of the main shaft 1. The space for the swash plate 3 to turn is provided by the relief grooves 42, so that the swash plate 3 The d...

Embodiment 2

[0049] A swash plate structure of an automobile air-conditioning compressor, which is different from Embodiment 1 in that the swash plate 3 is arranged in a split form. like Figure 5 As shown, the swash plate 3 includes a mounting seat 31 sheathed on the main shaft 1 and a disc body 32 fixed on the mounting seat 31 , the axis of the disc body 32 coincides with the axis of the main shaft 1 . The equi-cylindrical oblique holes 4 are arranged on the mounting seat 31, the mounting seat 31 includes a positioning convex ring 11, and the disk body 32 is correspondingly provided with a positioning groove 12 for the positioning convex ring 11 to be embedded, and the positioning convex ring 11 and the positioning groove The tight fit of 12 makes the disc body 32 and the mounting seat 31 fixedly connected together. The guide portion 13 , the limiting block 19 and the oil hole 16 are all located on the mounting seat 31 .

[0050] The split arrangement of the swash plate 3, because the ...

Embodiment 3

[0052] A car air-conditioning compressor, such as Image 6 As shown, including the body 20, the above-mentioned swash plate structure arranged in the body 20, the main shaft 1 is coaxially connected to the body 20, the body 20 is also provided with a piston 21 that cooperates with the swash plate 3, and the main shaft 1 passes through the body 20 One end of is connected with belt pulley 22. The pulley 22 is connected to the drive source to drive the main shaft 1 to rotate. When the main shaft 1 rotates, the swash plate 3 also rotates, and the edge of the swash plate 3 pushes the piston 21 to make axial reciprocating motions to realize compression, exhaust, expansion and suction. Work steps.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com