Crosshead for plunger pump and manufacturing method thereof

A processing and manufacturing, crosshead technology, which is applied to pump components, variable displacement pump components, components of pumping devices for elastic fluids, etc., can solve problems such as short service life, large processing errors, and complicated processing processes. Achieve the effects of reducing production costs, ensuring processing quality, and simplifying the processing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

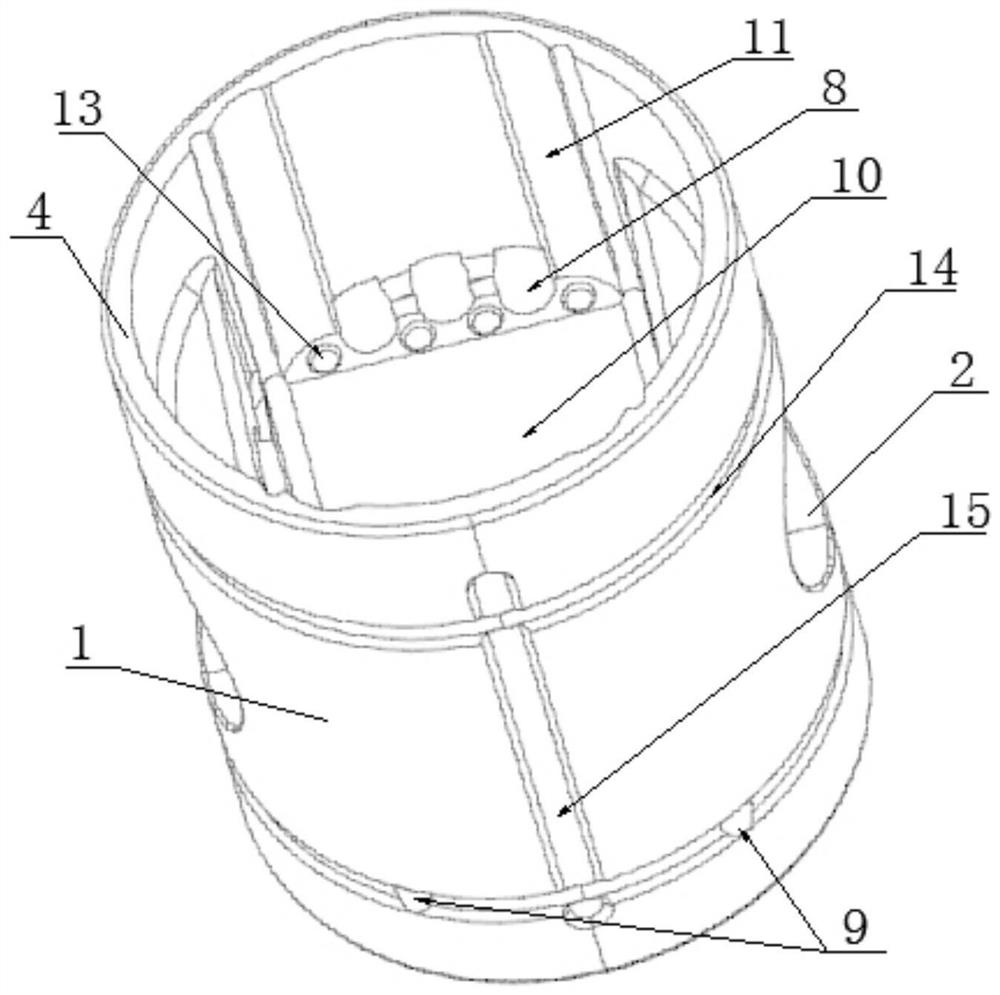

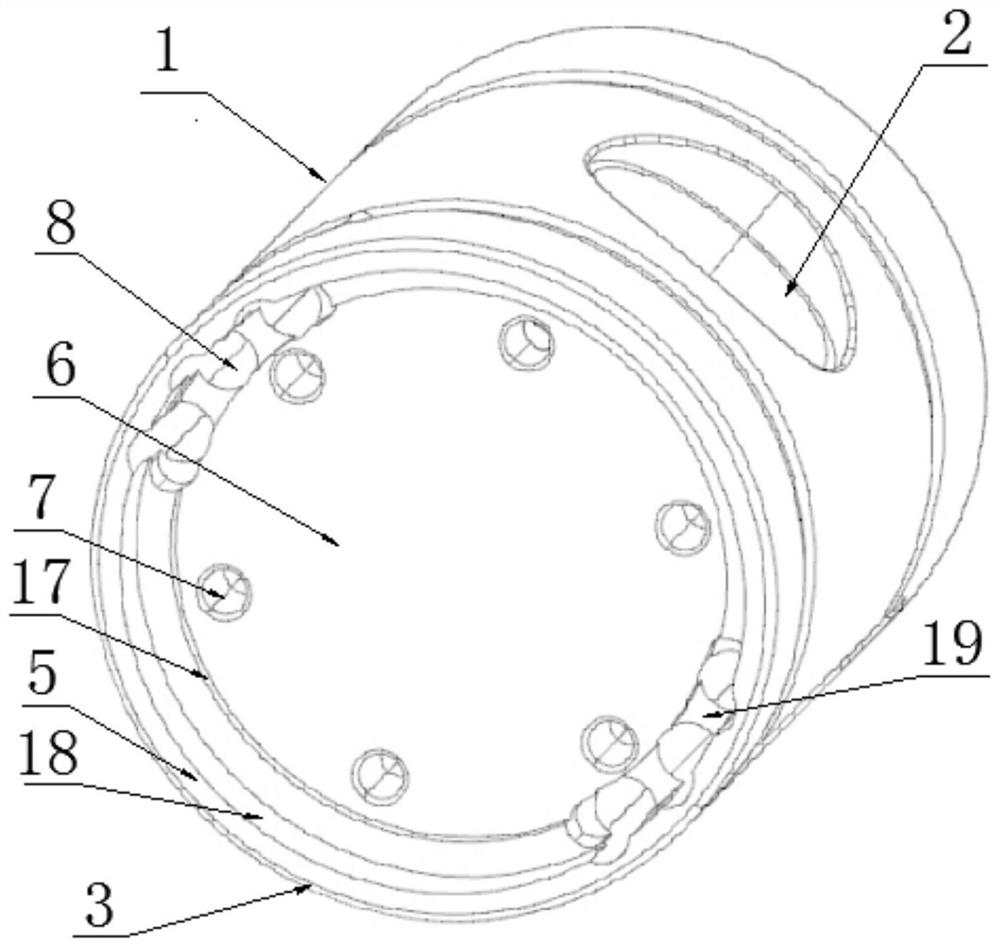

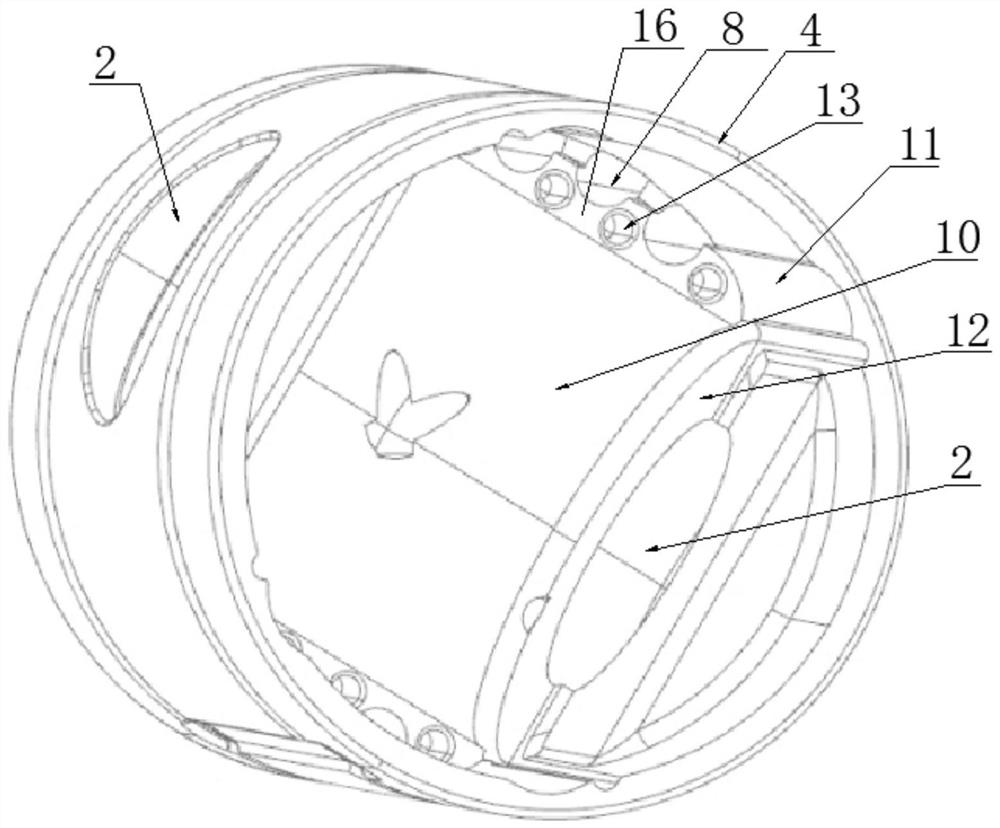

[0045] Embodiment 1 A crosshead for a plunger pump and its manufacturing method

[0046] Such as figure 1 As shown, the present invention provides a crosshead for a plunger pump, including a crosshead body 1, the crosshead body 1 is cylindrical with a cavity inside and one end is closed; There is an inner bottom surface 6; the inner bottom surface 6 divides the crosshead body 1 into two parts, top and bottom; the inner bottom surface 6 is arranged near the bottom end of the crosshead body 1; the top end of the crosshead body 1 is used for The connecting rod is mated and connected; the bottom end of the crosshead body 1 is used for mating connection with the push rod.

[0047] The outer circumference of the inner bottom surface 6 is provided with a notch, and the notch is a ring structure; the notch includes a notch circle 17 and a notch surface 18; two waist-shaped grooves 19 are arranged on the notch; The two waist grooves 19 are arranged symmetrically about the axis of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com