Direct feed type wiredrawing speed reducer

A wire-drawing reducer, straight-forward technology, applied in the directions of transmission parts, belts/chains/gears, mechanical equipment, etc., can solve the problems that affect the quality of wire-drawing, cannot be closer to the wire-drawing parts, and affect the stability of wire-drawing work. The effect of improving rigidity, high transmission efficiency and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

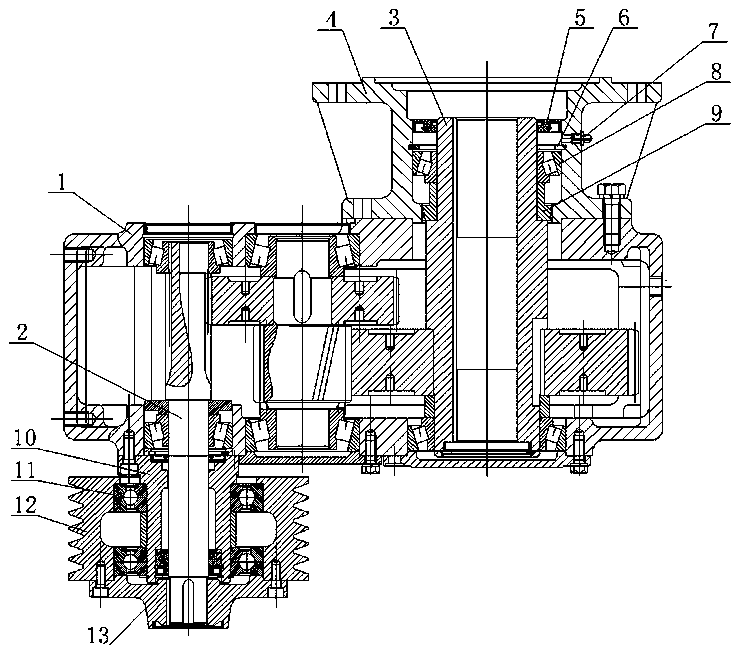

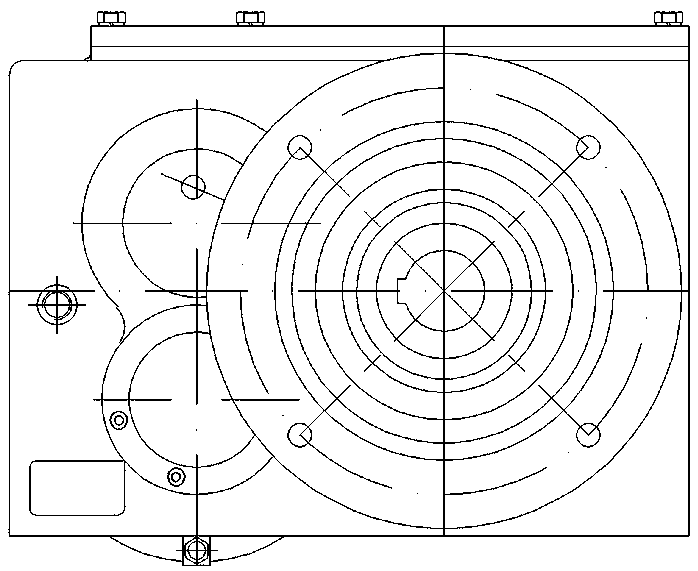

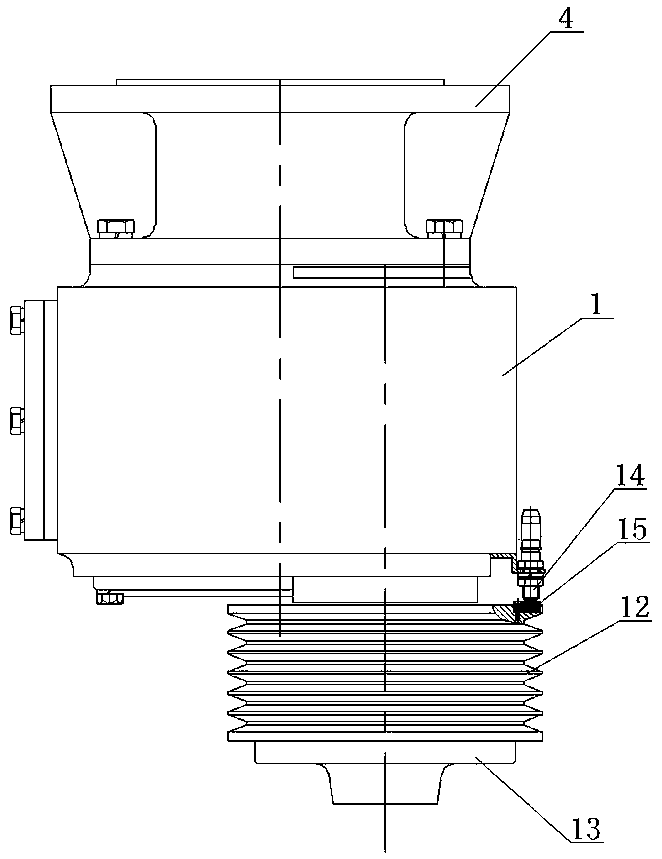

[0013] As shown in the figure, the linear drawing reducer of the present invention includes a box body 1 and an input shaft 2 and an output shaft 3 arranged vertically. The input shaft 2 transmits the output shaft 3 through gear reduction, and the upper shaft end of the output shaft 3 Rotation is supported by the tapered roller bearing 8 located in the inner hole of the connecting flange 4. The connecting flange 4 makes the upper shaft end of the output shaft 3 support higher than the top of the box body 1, and the connecting flange 4 is fixedly installed on the top of the box body 1. The upper end surface of the outer ring of the tapered rolling bearing 8 is axially limited by the retaining ring 6 for the hole, and the sealing ring 5 for sealing the shaft end of the output shaft 3 is arranged above the retaining ring 6 for the hole, and the sealing ring 5 and the tapered rolling bearing The inner hole wall of the connecting flange between 8 is provided with a grease injection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com