Silent throttling valve and throttling valve component

A technology of throttle valve and syllable, which is applied in the direction of sliding valve, valve detail, valve device, etc., can solve the problem of high noise of the throttle valve, reduce the impact noise, improve the problem of valve core rotation, and reduce the contact area. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

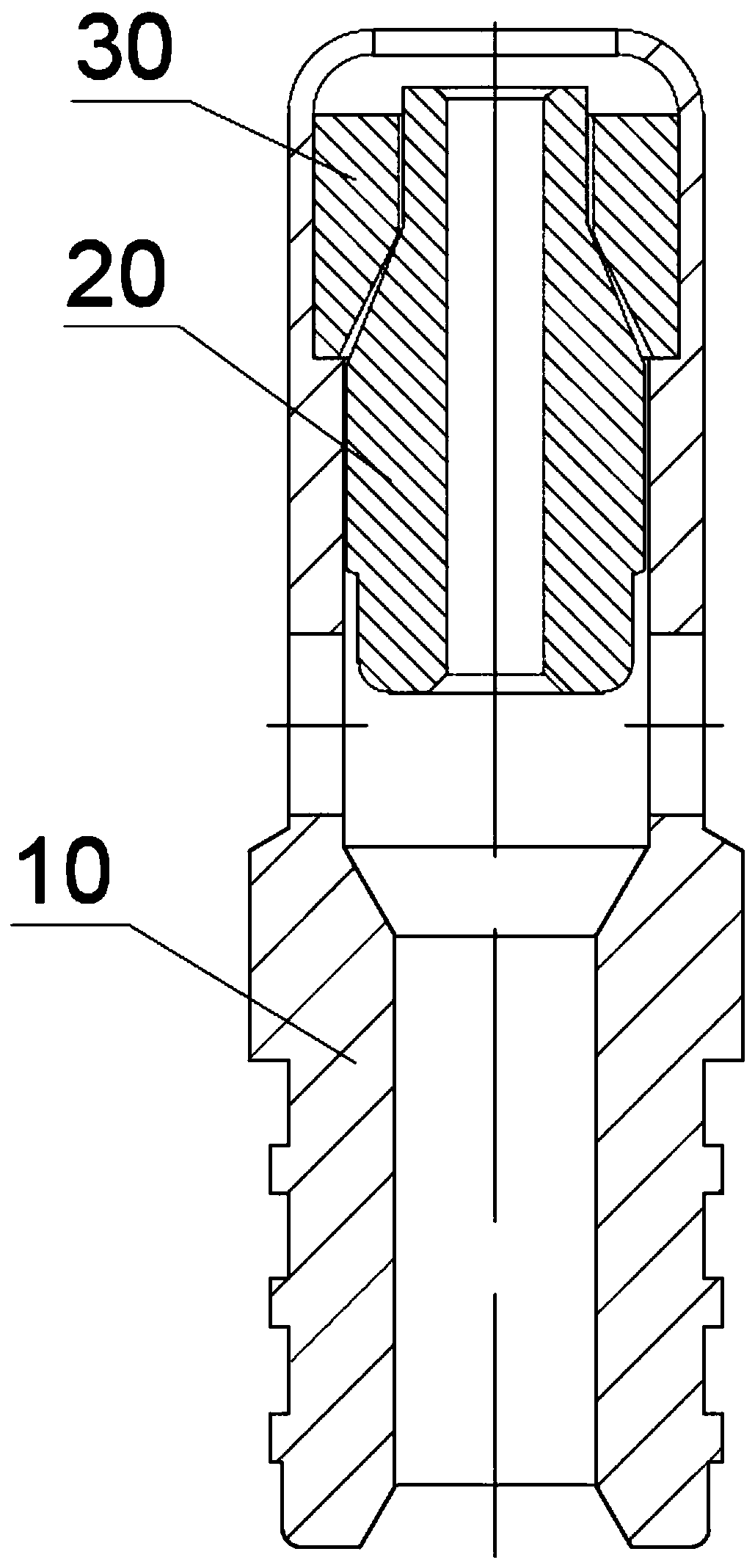

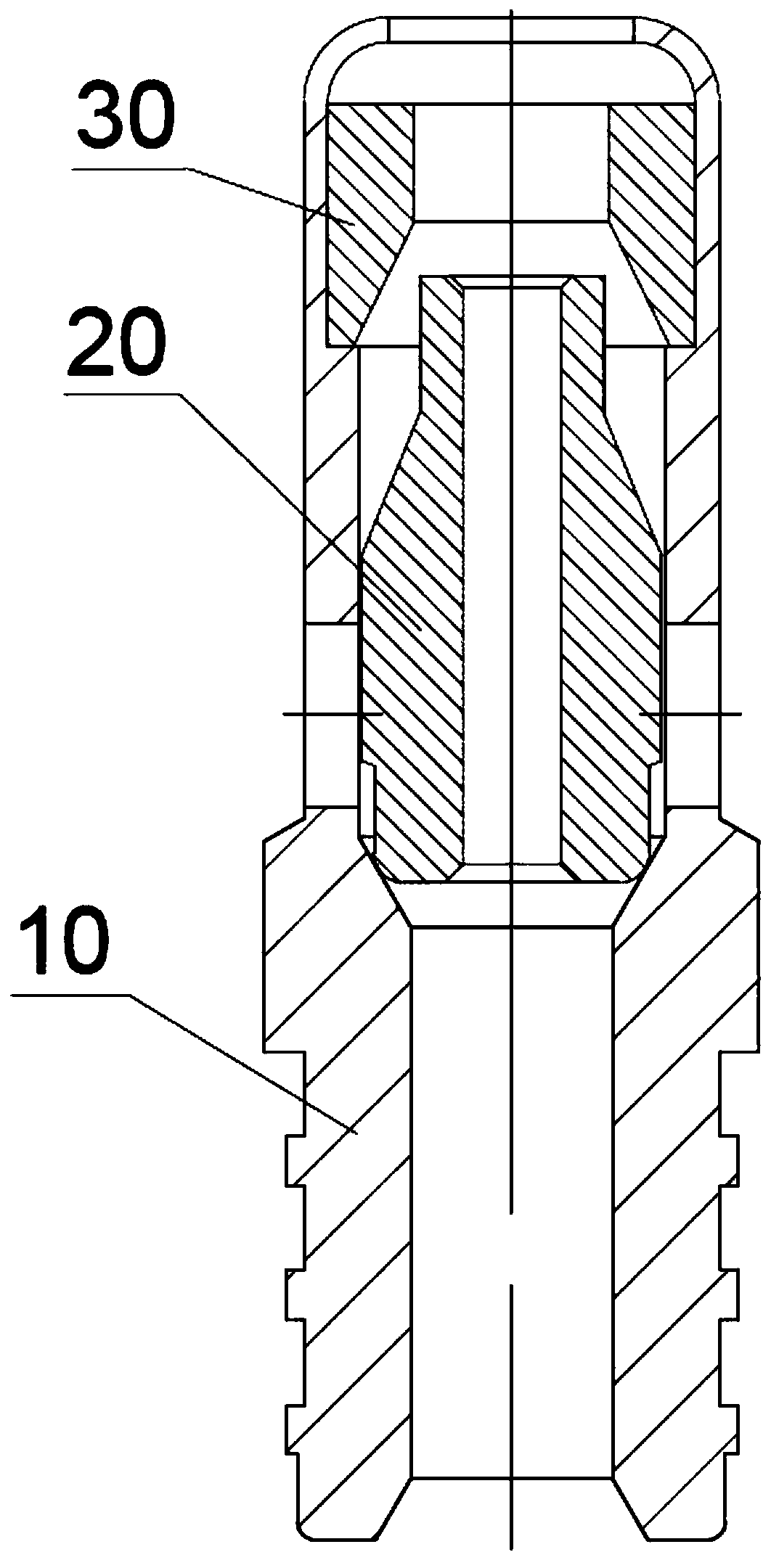

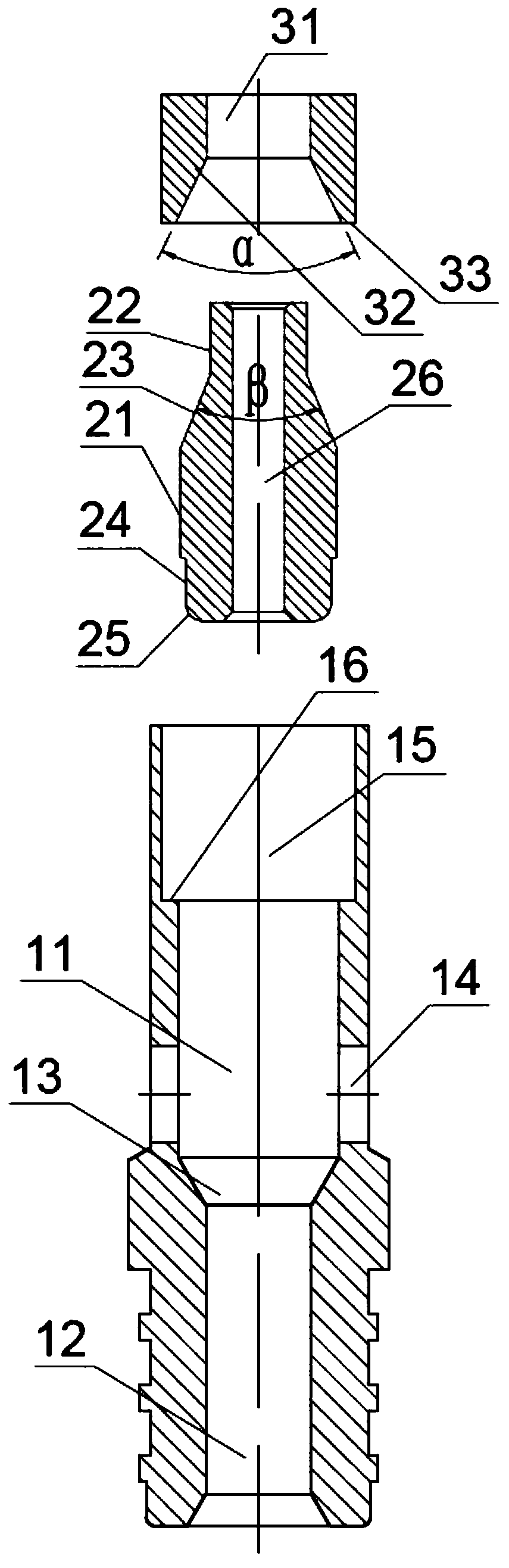

[0046] A throttle valve of this embodiment, such as Figure 1-3 As shown, it includes a valve seat 10 , a valve core 20 and a retaining ring 30 . Wherein, the valve seat 10 is provided with a valve hole 12 communicating with each other and a valve core cavity 11 for installing the valve core 20 , and the valve core 20 can move axially in the valve core cavity 11 .

[0047] Wherein, the inner diameter of the valve core cavity 11 is larger than the inner diameter of the valve hole 12 , and a transition cone surface 13 is provided between the valve core cavity 11 and the valve hole 12 .

[0048] In this embodiment, two liquid flow passages 14 radially penetrating through the wall of the valve core cavity 11 are provided along the circumferential direction near the transition cone surface 13 on the cavity wall of the valve core cavity 11 . Of course, the number of liquid flow channels 14 can be one, or more than two, preferably two.

[0049] In this embodiment, the end of the va...

Embodiment 2

[0059] Such as Figure 5 As shown, the silent throttle valve of this embodiment differs from the first embodiment in that an arc-shaped transition surface 34 is provided at the position where the inner taper hole of the retaining ring connects with the guide hole. The purpose of such setting is that when the retaining ring collides with the outer cone surface on the valve core, the arc surface where the arc-shaped transition surface is located will cause less damage to the outer cone surface, which is beneficial to improve the life of the silent throttle valve.

Embodiment 3

[0061] Such as Figure 6 As shown, a one-way throttle valve assembly of this embodiment includes a valve pipe 40, and the valve pipe 40 is provided with a valve seat installation chamber 41, and the valve seat installation chamber 41 is provided with the mute valve of the first embodiment. Throttle valve, and in the valve tube in this embodiment, filter screens 42 are provided at both ends of the throttle valve.

[0062] Preferably, the filter screen 42 in this embodiment is made of stainless steel with a mesh size of 50-150 mesh.

[0063] It should be noted that this embodiment is a specific application occasion of the silent throttle valve of Embodiment 1. The throttle valve assembly of this embodiment can be directly applied to an air conditioner, and its two ends are connected to the refrigerant pipeline of the air conditioner. . The throttle valve assembly with this structure also has the silent technical advantage of the silent throttle valve in the first embodiment, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com