Method for quantitative analysis of brightener in copper foil electrolyte

A quantitative analysis and brightener technology, which is applied in the direction of material analysis, material analysis, and material electrochemical variables through electromagnetic means, can solve problems such as unproposed solutions, and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Take 50mL of the detection matrix solution to the reaction tank, connect the three-electrode system, and select the cyclic voltammetry to run the electrochemical workstation to obtain the initial voltammetry characteristic curve.

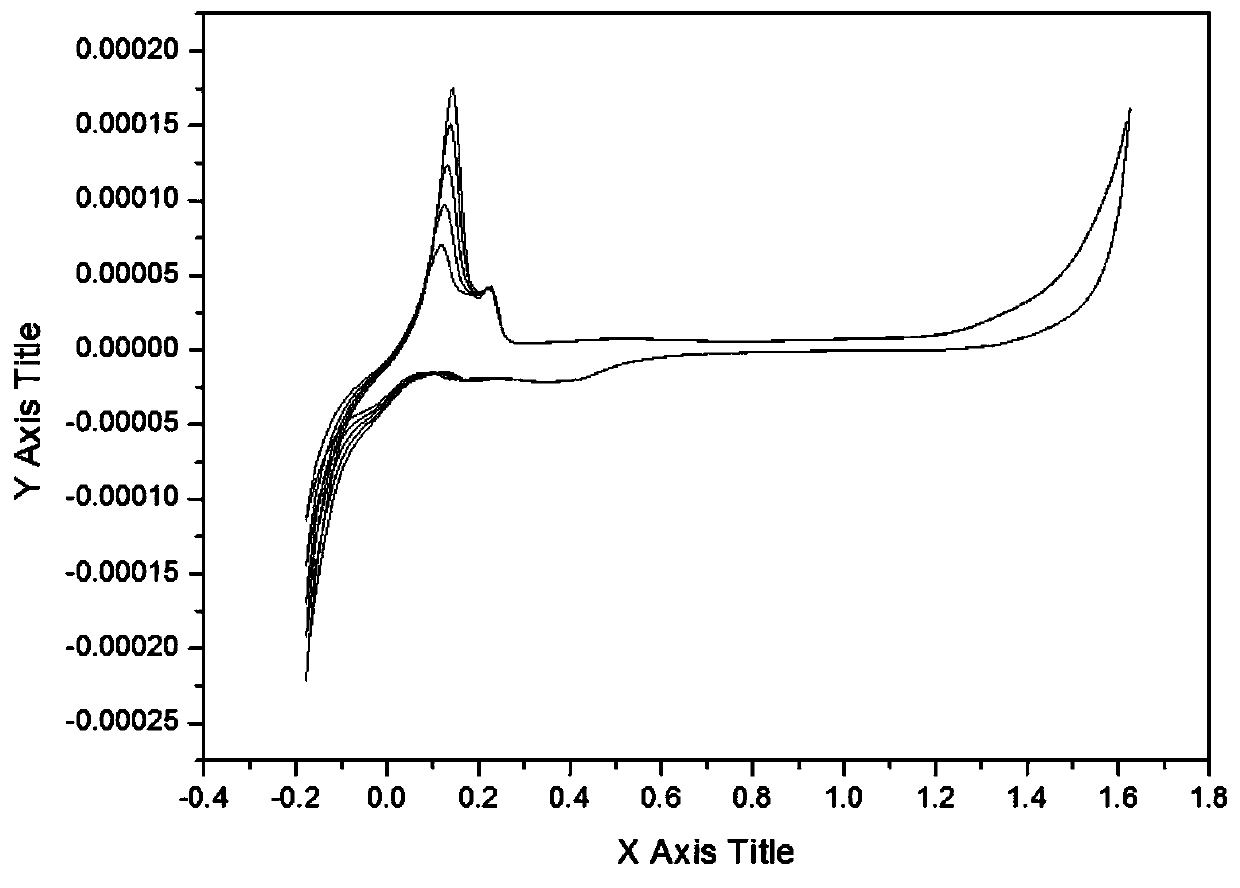

[0044] Add 1mL sample to the reaction tank, run the electrochemical workstation to obtain the volt-ampere characteristic curve after adding the sample, add 0.1mL brightener standard solution to the reaction tank three times, run the workstation respectively, and obtain a total of 5 volt-ampere characteristic curves as follows: figure 1 shown.

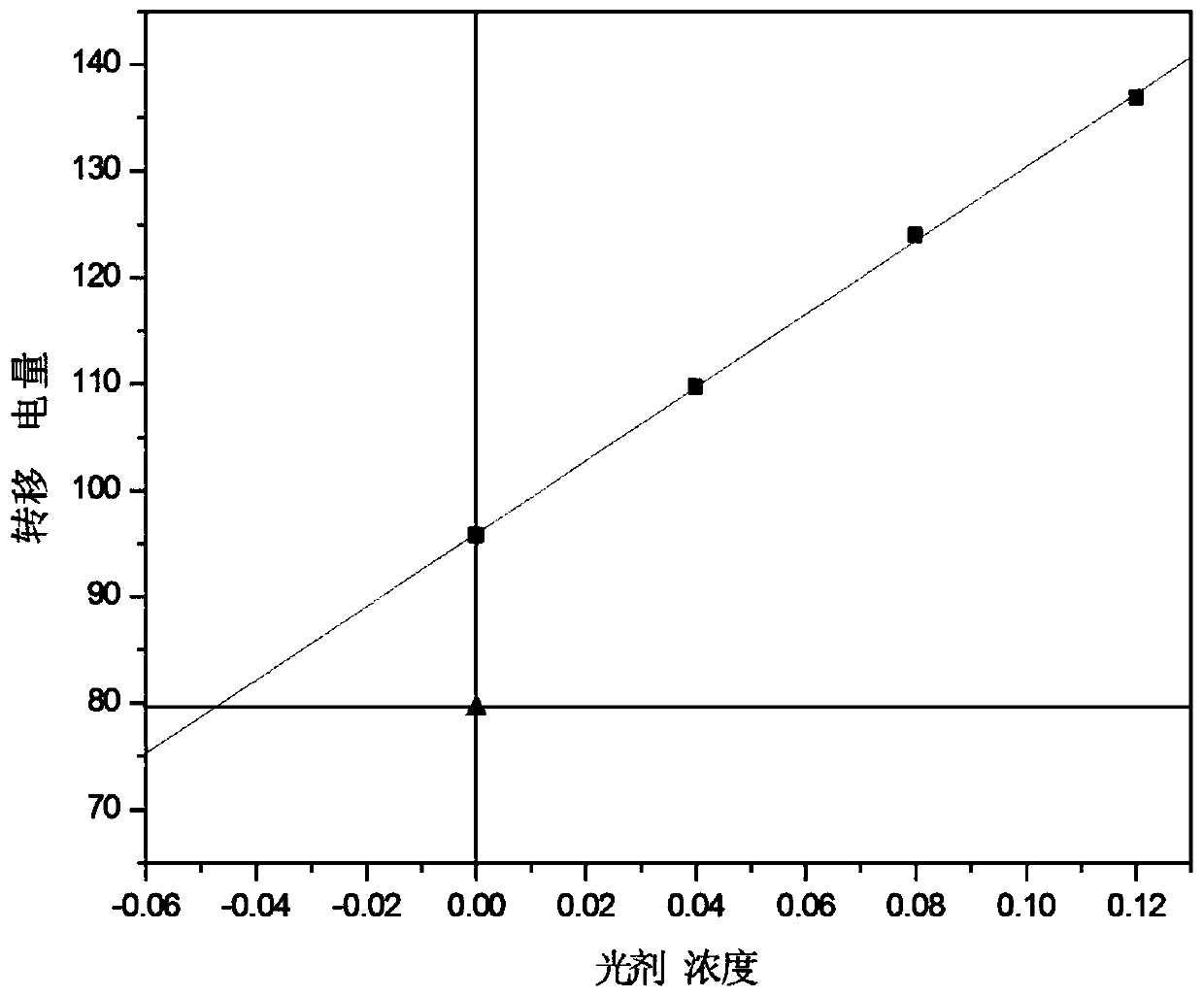

[0045] Process the volt-ampere characteristic curve, calculate the corresponding transfer electricity according to the integral area of each curve, and obtain the brightener concentration-transfer electricity curve as figure 2 As shown, the correction determination coefficient R=0.99978≥0.999.

[0046] Calculate the concentration of brightener in the sample according to the intercept of the curve ...

Embodiment 2

[0048] Take 50mL of the detection matrix solution to the reaction tank, connect the three-electrode system, and select the cyclic voltammetry to run the electrochemical workstation to obtain the initial voltammetry characteristic curve.

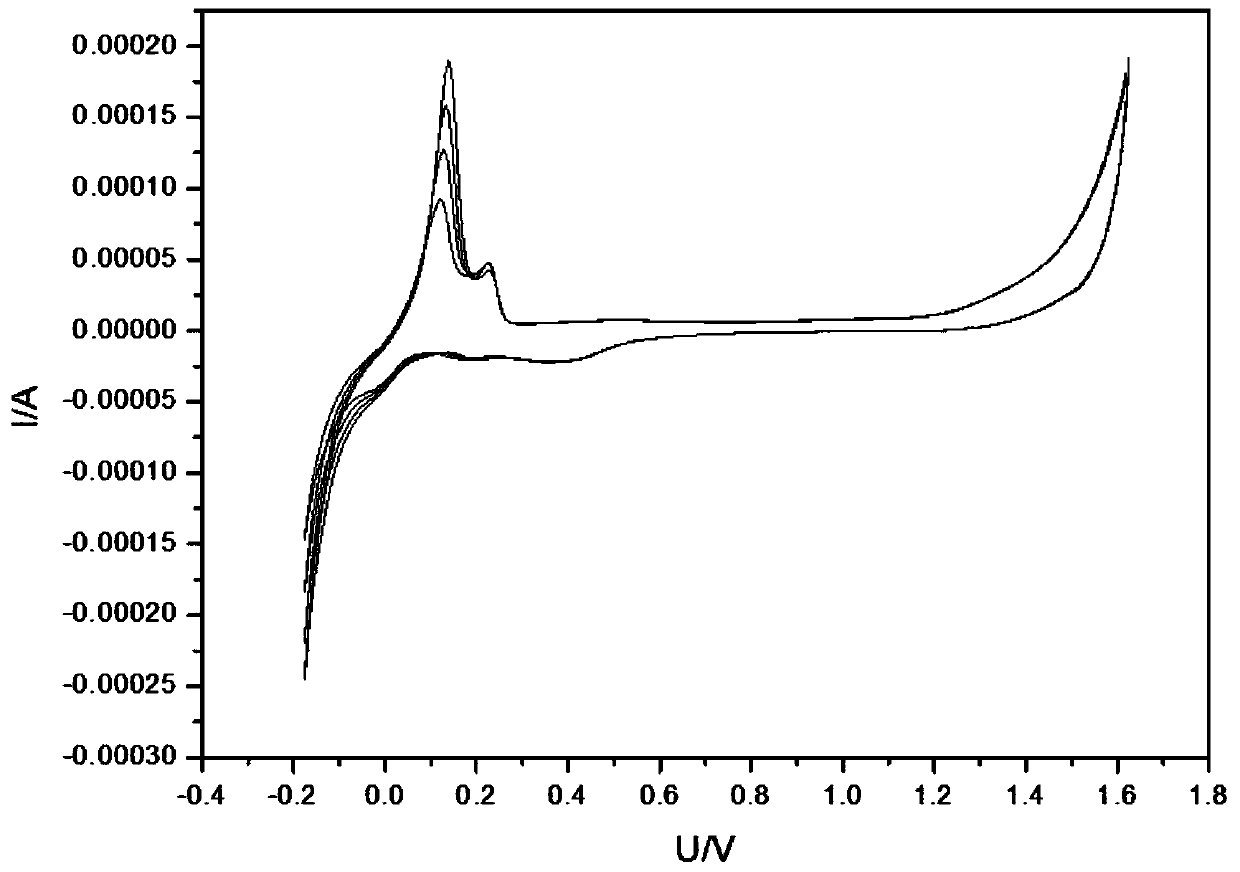

[0049]Add 1mL sample to the reaction tank, run the electrochemical workstation to obtain the volt-ampere characteristic curve after adding the sample, add 0.1mL brightener standard solution to the reaction tank twice, run the workstation respectively, and obtain a total of 4 volt-ampere characteristic curves as follows: image 3 shown.

[0050] Process the volt-ampere characteristic curve, calculate the corresponding transfer electricity according to the integral area of each curve, and obtain the brightener concentration-transfer electricity curve as Figure 4 As shown, the correction determination coefficient R=0.99924≥0.999.

[0051] Calculate the concentration of brightener in the sample according to the intercept of the curve

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com