Radar speed measurement equipment with debugging mechanism easy to assemble and disassemble

A radar speed measurement, easy loading and unloading technology, applied in measurement devices, radio wave measurement systems, radio wave reflection/re-radiation and other directions, can solve the problems of long construction period, high cost, single assembly method, etc., to achieve simple and convenient construction operation , Low cost and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

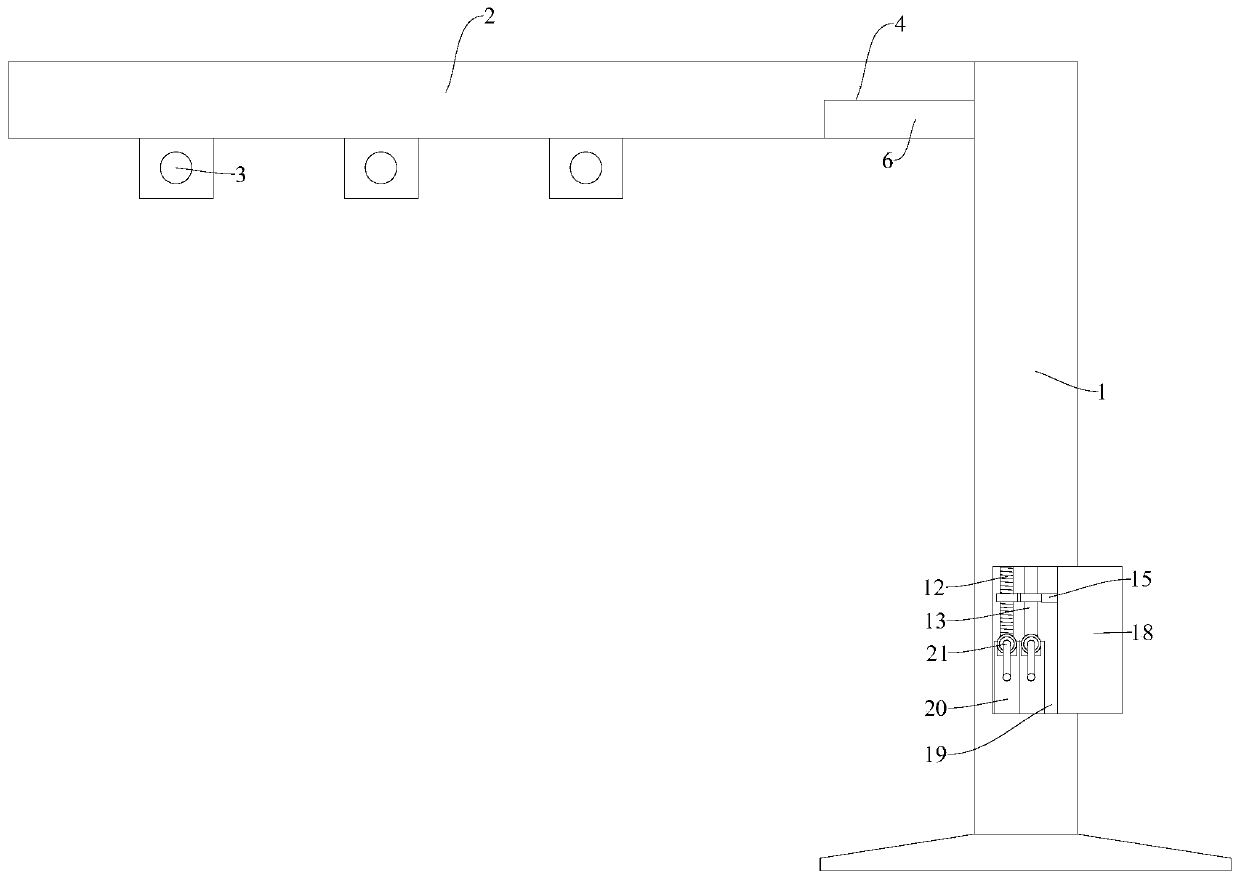

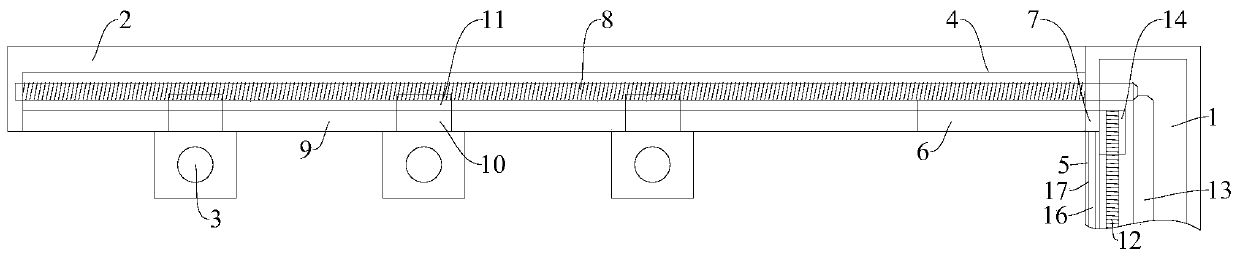

[0018] Embodiment: Turn the rotating shaft 21 upwards so that the bevel gear at the top of the rotating shaft 21 meshes with the bevel gears at the bottom end of the first vertical lifting screw 12 and the bottom end of the second longitudinal adjusting screw 13 at the corresponding positions, and then rotate To control the lifting and translation, the display controls the rotation of the second longitudinal adjustment screw rod 13, and then the second longitudinal adjustment screw rod 13 controls the rotation of the top external thread adjustment screw rod 8, and the top external thread adjustment screw rod 8 drives the radar speed measurement through rotation. The shooting device 3 moves from the lower end of the horizontal fixed rod 2 to the lower end of the bottom lifting seat 6, and then controls the rotation of the first vertical lifting screw rod 12, and the first vertical lifting screw rod 12 drives the bottom lifting seat 6 to lift, thereby driving the shooting equipmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com