Manufacturing method of visual inspection defect library for practical training

A technology of visual inspection and production method, which is applied in the field of visual inspection, can solve the problems that students do not understand the shooting images, and achieve the effect of strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is described further now.

[0030] A method for making a visual inspection defect library for practical training includes the following steps:

[0031] S1. Take pictures of defective workpieces to obtain defect images, and adjust the exposure time of the camera when taking pictures so that the camera can take clear images and save them;

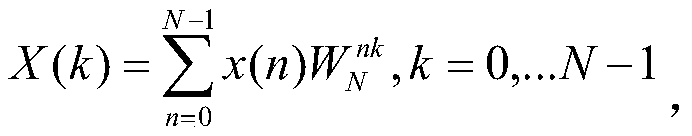

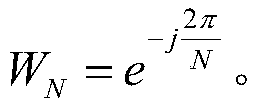

[0032] S2. Optimizing the fft speed according to the size of the specified image;

[0033] S3. Construct a Gaussian filter GaussFilter, and process the defect image through the Gaussian filter to obtain a Gaussian image. The parameters of the Gaussian filter include the standard deviation of Gaussian in the main direction, the standard deviation of Gaussian in the main direction orthogonal to the main direction, and the filter The angle of the main direction, the position of the DC term in the frequency domain;

[0034] S4, taking the gray value, and subtracting the gray value of the defect image and the Gaussia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com