Continuous paper covering cutting device for battery continuous pole plates

A battery and polar plate technology, which is applied in the field of continuous paper-coated cutting devices, can solve problems such as low precision, large deviation in the cutting size of coated paper, and cracking of lead plaster.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

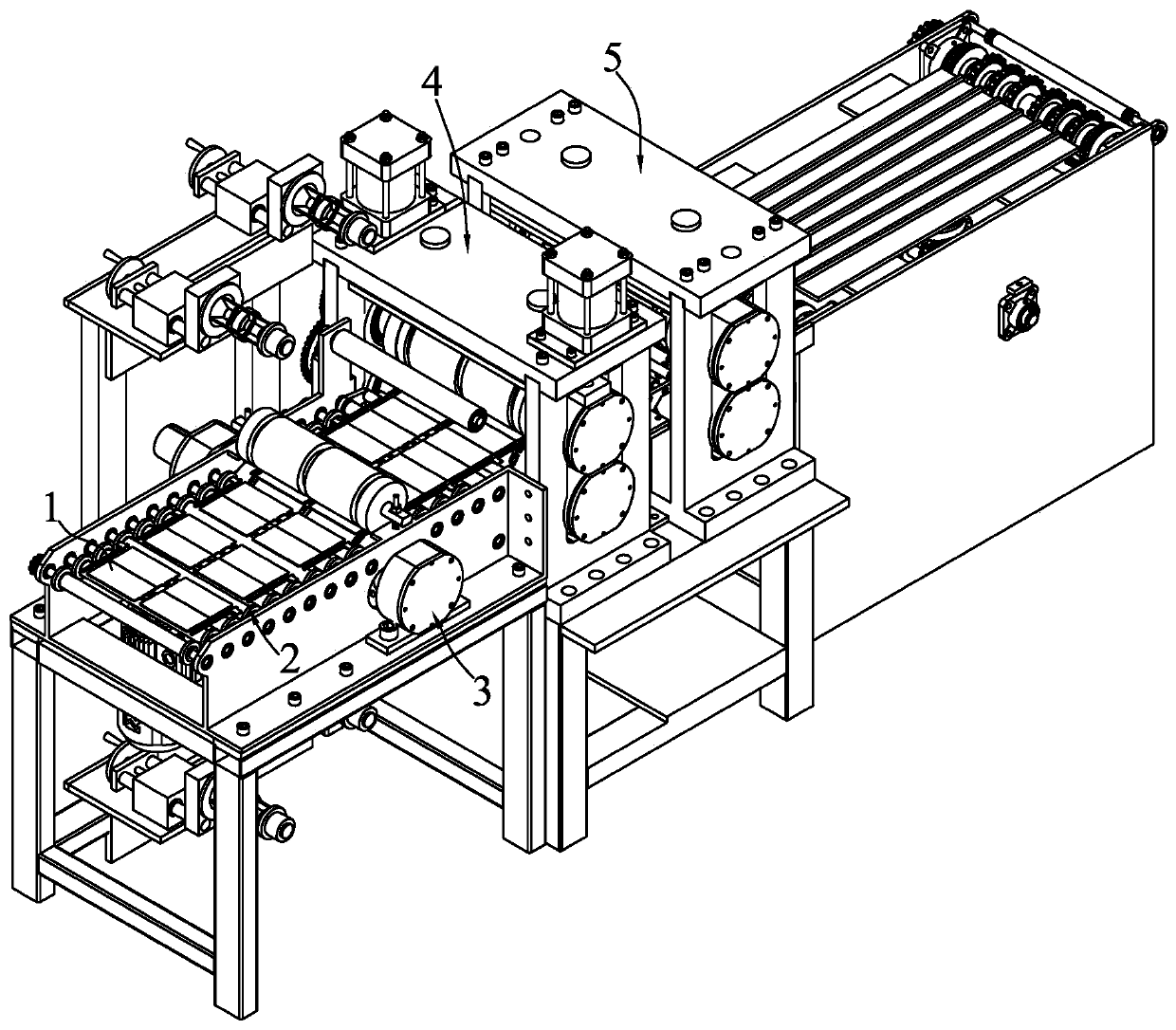

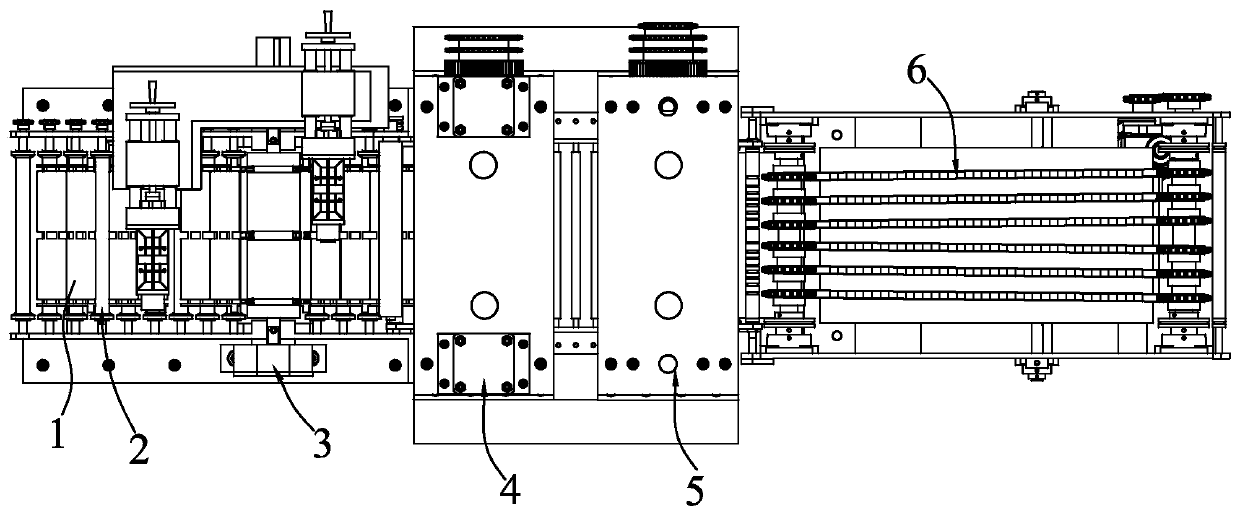

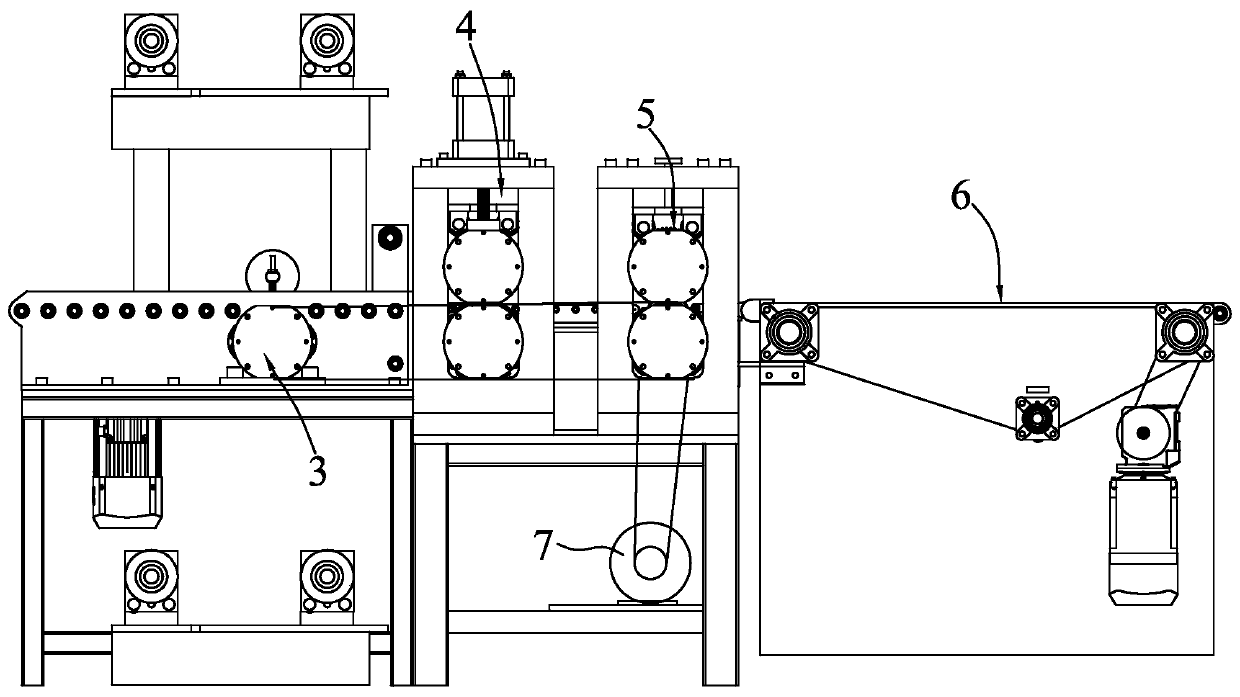

[0041] Such as Figure 1-14 As shown in the figure, a continuous paper-coated cutting device for battery connected plates is used to directly coat both sides of the plates with paste after the plates are made of paste. Board paper, and then cut the continuous plate to obtain a single plate covered with paper. Such as Figure 13 As shown, each connected pole plate 1 includes four single-piece pole plates 11 arranged in a 2×2 arrangement, and each single-piece pole plate 11 includes a pole plate body 12 and a tab 13 arranged on one side of the pole plate body 12 , connecting strips 14 are provided on both sides of the connected pole plates 1, and the adjacent single-piece pole plates 11 and between the single-piece pole plates 11 and the connecting strips 14 are connected by tabs 13 or connecting lugs 15, as shown in Figure 13 In the illustrated embodiment, the two single-piece pole plates 11 along the length direction of the single-piece pole plate 11 are connected by two tab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com