Laminating device

A lamination device and lamination technology, applied in lamination devices, lamination, instruments, etc., can solve problems such as inability to properly affix the second workpiece, inability to adhere to rollers, etc., and achieve low cost of introduction , the effect of simplifying the overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] ﹝Example﹞

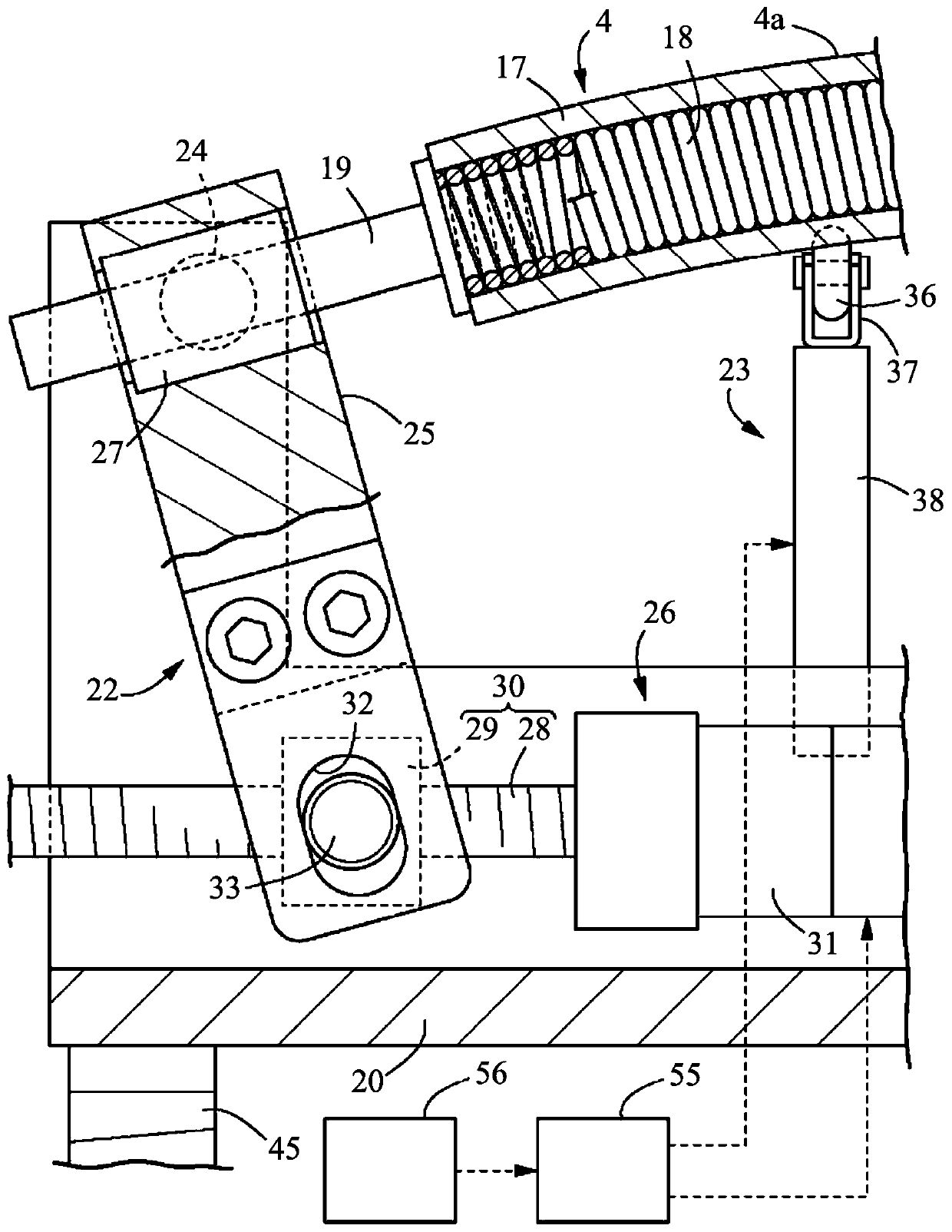

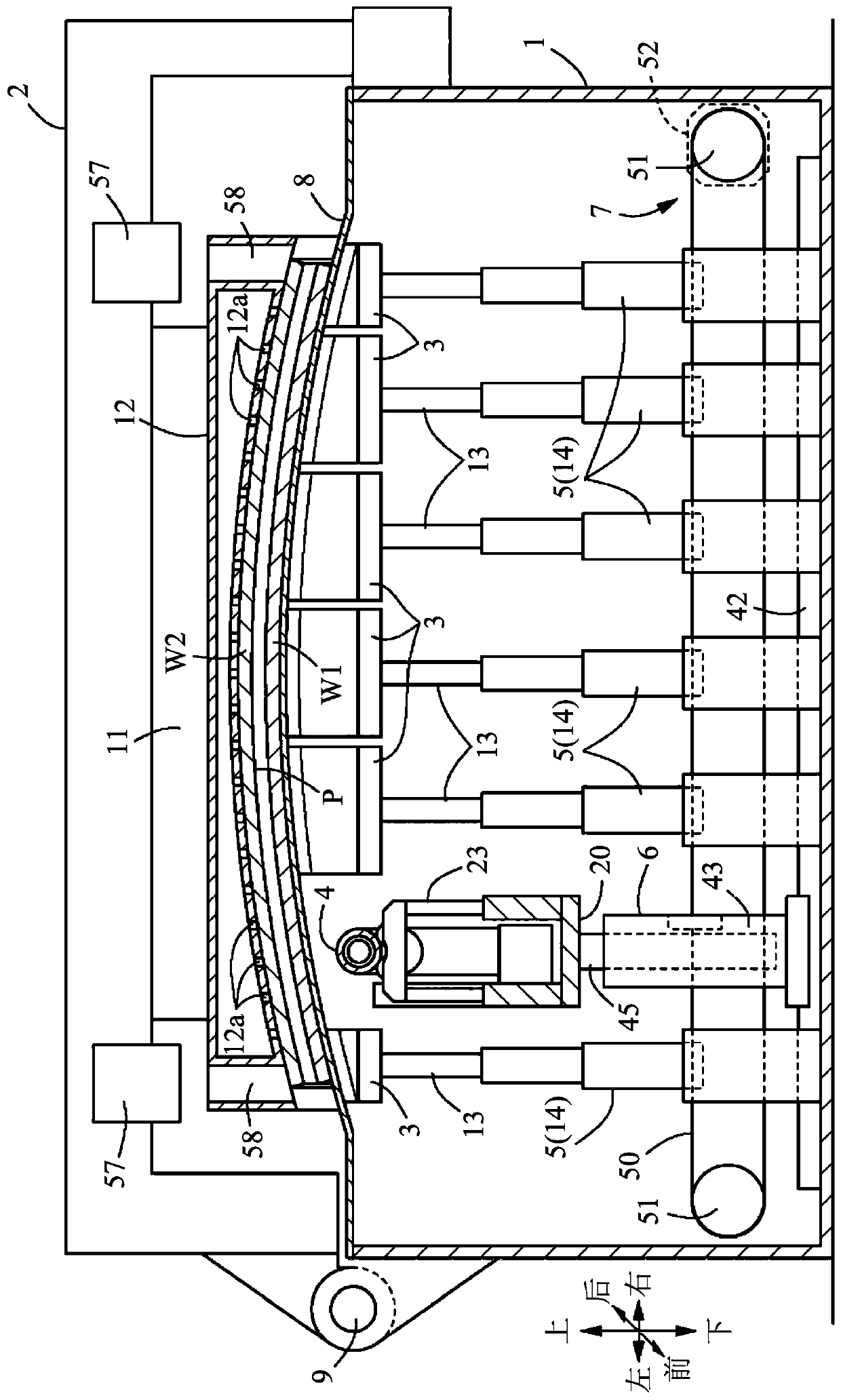

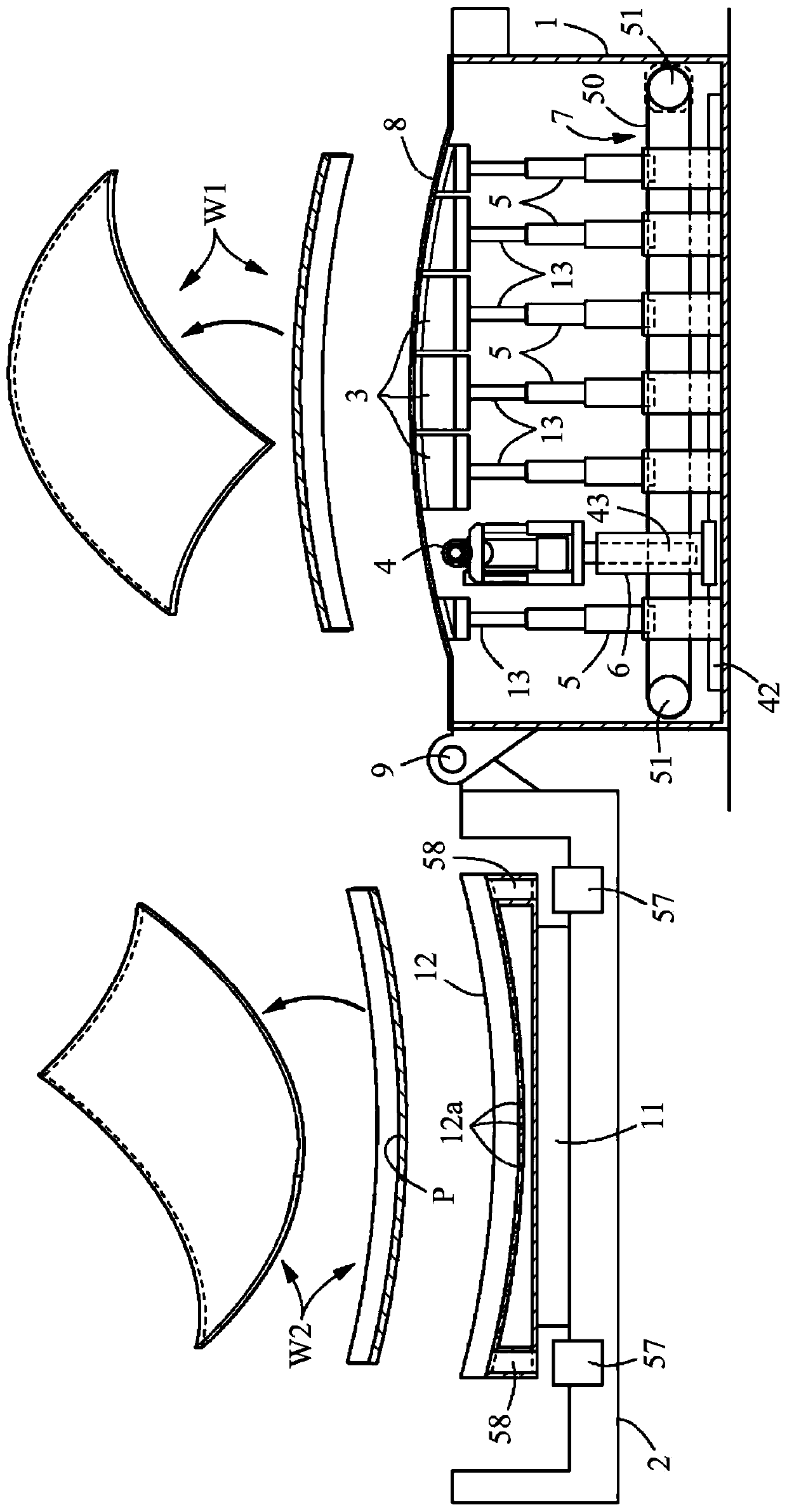

[0046] Figure 1 to Figure 1 1 shows an embodiment of the bonding device of the present invention. Front and back, left and right, and up and down in the present invention are contrasted with figure 2 The crossed arrows shown and the front and rear, left and right, and up and down displays marked near each arrow. like figure 2 As shown, the bonding apparatus includes: a base (first base) 1 with an open upper surface; and a movable base (second base) 2 supported by the base 1 so as to be swingable to open and close. The interior of the base 1 is provided with: six first adsorption tables 3, which adsorb and maintain the first workpiece W1 into a three-dimensional plane; laminating rollers 4; an adsorption table lifting structure 5 for lifting and lowering the first adsorption table 3; The roller lifting structure 6 of the bonding roller 4; and the roller moving structure 7, move and operate the bonding roller 4 between the bonding start end and the bond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com