Integrated methanol separation and methanol-to-gasoline conversion process

A methanol conversion, methanol technology, applied in the petroleum industry, ether preparation, organic chemistry, etc., can solve the problems of large heat exchange network, high compression cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1- 1

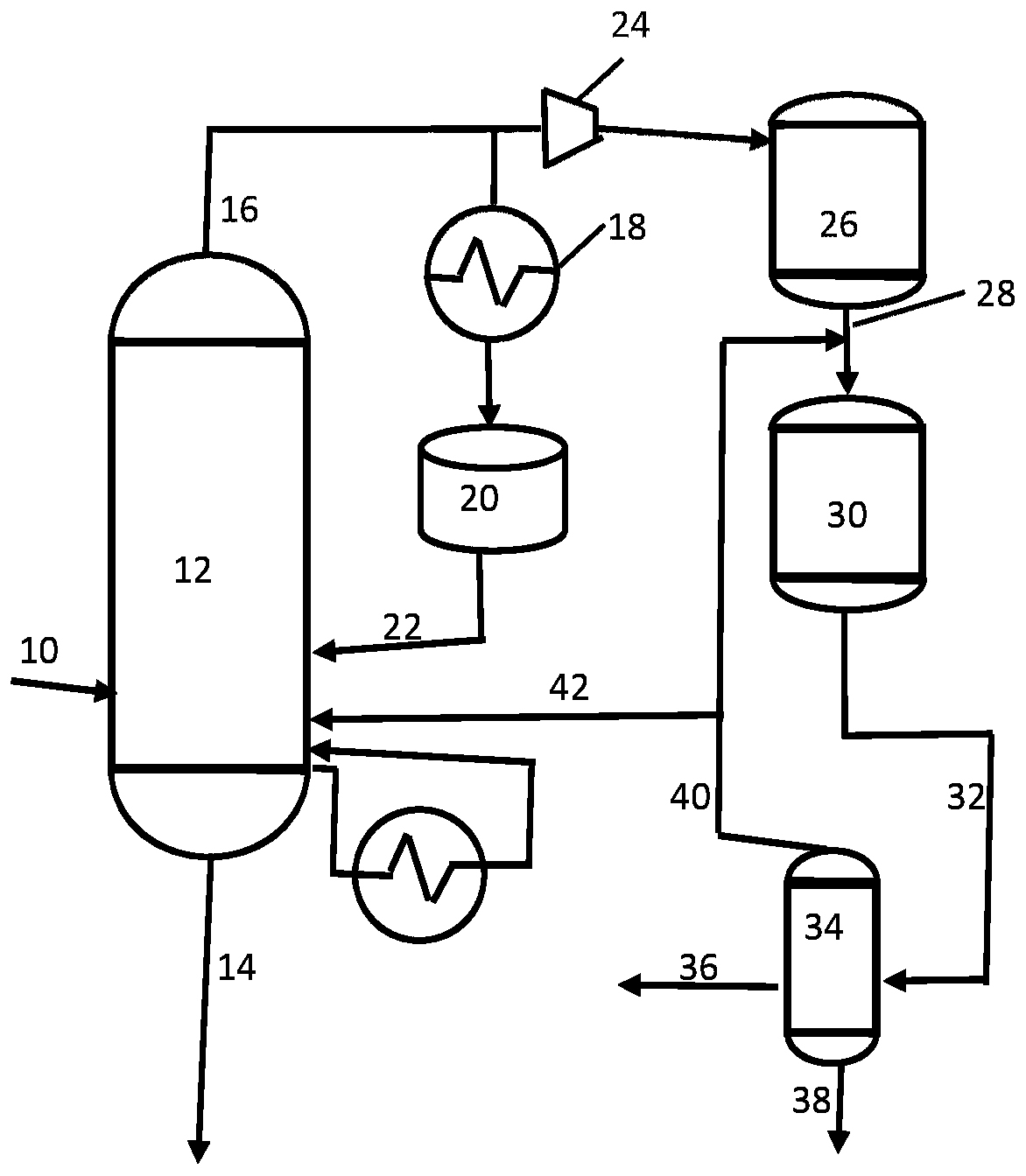

[0042] Embodiment 1 - A method of converting methanol to gasoline boiling range hydrocarbons comprising: feeding crude methanol from a methanol synthesis reactor to a methanol separation vessel to recover a methanol stream in the gas phase; In the case of a methanol stream, the methanol stream in the gas phase is fed to a reactor containing a conversion catalyst to convert the methanol to at least one of dimethyl ether or gasoline boiling range hydrocarbons.

Embodiment approach 2- 1

[0043] Embodiment 2 - A method of converting methanol to gasoline boiling range hydrocarbons comprising: feeding crude methanol from a methanol synthesis reactor to a methanol separation vessel to recover a methanol stream in the gas phase; The methanol stream is fed to a reactor containing a conversion catalyst to convert methanol to at least one of dimethyl ether or gasoline boiling range hydrocarbons, wherein the separation vessel is at substantially the same pressure as the reactor.

Embodiment approach 3- 1

[0044] Embodiment 3 - A method of converting methanol to gasoline boiling range hydrocarbons comprising: feeding crude methanol from a methanol synthesis reactor to a methanol separation vessel to recover a methanol stream in the gas phase; In the case of the methanol stream, the methanol stream is compressed and the methanol stream in the gas phase is fed to a reactor containing a conversion catalyst to convert the methanol to at least one of dimethyl ether or gasoline boiling range hydrocarbons.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com