Actuator for an automated or automatic transmission, and method for controlling said actuator

A technology of automatic transmission and actuator, which is applied in the direction of transmission control, engine components, components with teeth, etc., to achieve the effect of good damping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

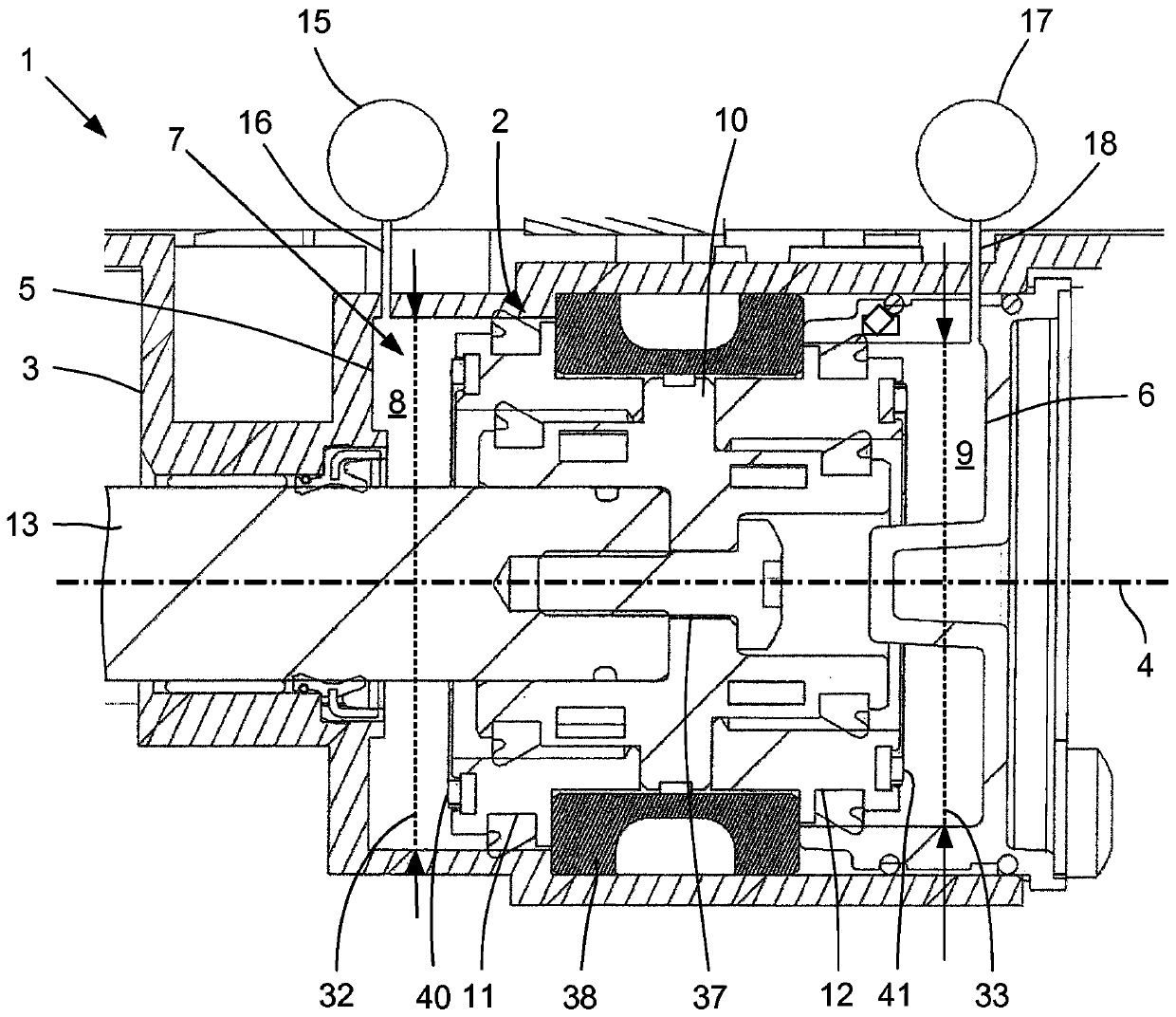

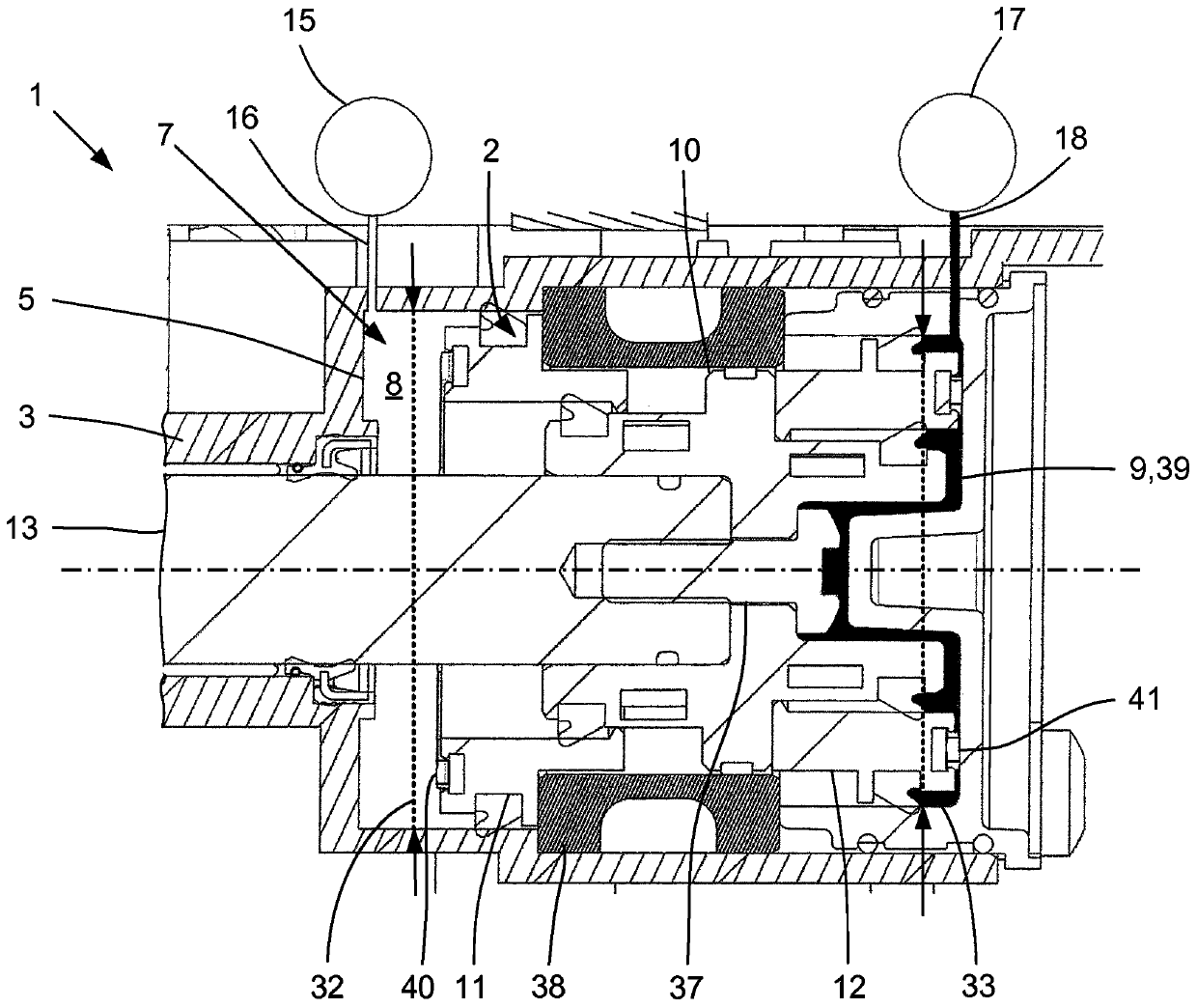

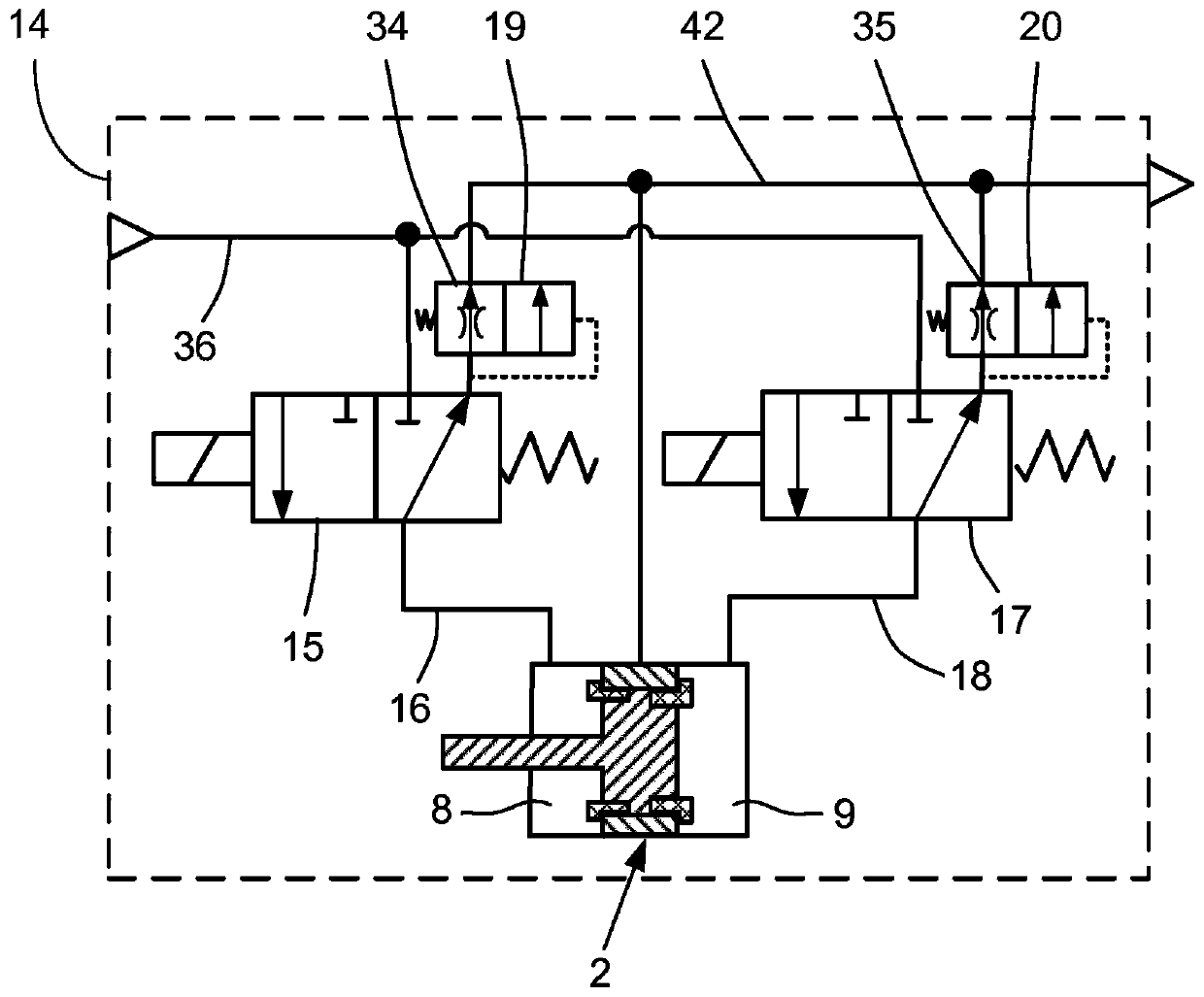

[0050] specific implementation plan

[0051] automatic transmission figure 1 with figure 2 The actuator 1 shown has a piston unit 2 in the form of a shifting piston, which is slidably arranged coaxially with the longitudinal axis 4 in a cylinder housing 3 in the form of a shifting cylinder. The piston unit 2 moves between the first end stop surface 5 and the second end stop surface 6 in the piston chamber 7 of the cylinder housing 3, wherein the piston unit 2 divides the piston chamber 7 into two compressible Air pressure chambers 8 , 9 are sealed relative to each other. The piston unit 2 comprises a main piston 10 and two auxiliary pistons 11 , 12 . Fastened to the main piston 10 is a piston rod 13 , which is mounted slidingly in the cylinder housing 3 and is guided along the longitudinal axis 4 . The connection between the main piston 10 and the piston rod 13 is realized, for example, as a second screw connection 37 .

[0052] The piston rod 13 engages or is operativel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com