Drill bit guider for high tibial osteotomy

A guider and drill bit technology, which is applied in the direction of bone drill guidance, medical science, surgery, etc., can solve the problems of reducing operation efficiency, inaccurate drilling angle, affecting the shape of long groove, etc., so as to improve operation efficiency and reduce drilling Difficulty, the effect of ensuring drilling accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

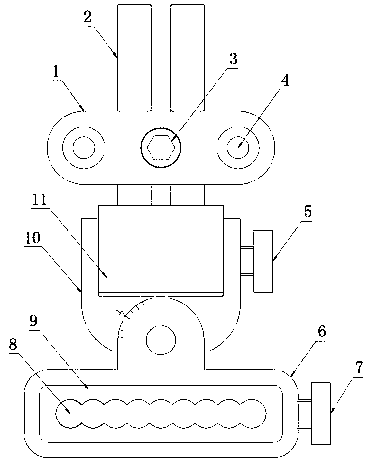

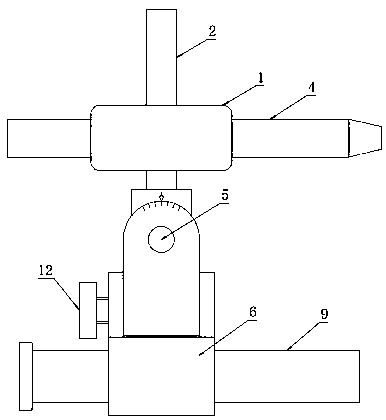

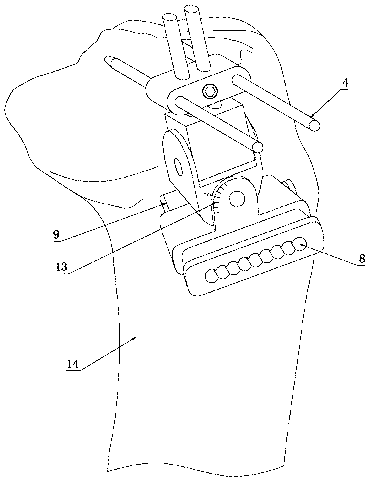

[0019] see Figure 1 ~ Figure 3 , the present invention includes a positioning rod 4, a positioning block 1, a sliding rod 2, a sliding rod locking bolt 3, a drilling module 9 and a universal adjustment mechanism, wherein the universal adjustment mechanism includes a rotating arm locking bolt 5, a guide sleeve 6, Drilling mold locking bolt 7, U-shaped arm 10, lifting block 11 and guide sleeve locking bolt 12.

[0020] Two positioning rods 4 are provided, and their front ends are inserted into the patient's knee joint cavity, that is, clamped between the patient's tibia and femur, and its effect is to position the whole device. The positioning block 1 is fixed on the middle part or the rear end of the positioning rod 4, two mutually parallel sliding rods 2 pass through the through holes on the positioning block 1 and are locked by the sliding rod locking bolt 3, and the sliding rod locking bolt 3 is screwed on The threaded hole on the positioning block 1 is pushed against the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com